Rev Up Your Savings: A Comprehensive Guide to DIY Electric Car Battery Cost

If you are looking to make the switch to an electric vehicle, you may have wondered about the cost of the DIY electric car battery. While converting a gas car to electric can be a daunting task, it can also be an exciting and fulfilling project for those interested in sustainable, environmentally-friendly transportation. One major consideration for DIY electric car enthusiasts is the cost of the battery.

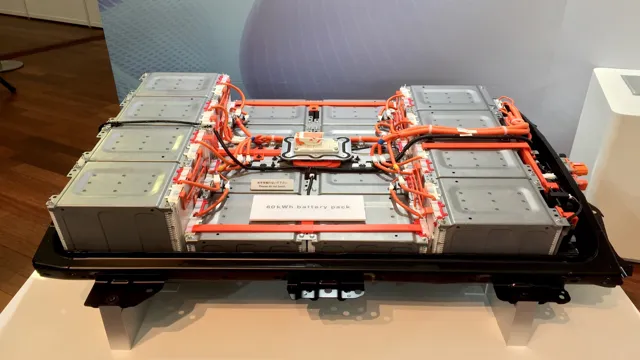

After all, the battery is the heart of the electric vehicle, and it can be expensive to purchase. However, the cost of the battery can vary widely depending on several factors. Some of these factors include the size of the battery, the type of battery, and the age and condition of the used battery being repurposed.

Additionally, the cost of the battery can be impacted by the availability of materials and components necessary to build the battery. Despite these considerations, there are ways to save on the cost of your DIY electric car battery. One option is to source used batteries from electric vehicles that have been decommissioned or are no longer operational.

Another option is to purchase new batteries in bulk to take advantage of wholesale pricing. Overall, while the cost of the DIY electric car battery may be a significant consideration, it should not discourage you from pursuing your dreams of converting a gas car to electric. With proper planning, research, and sourcing of materials, you can build a sustainable, efficient electric vehicle at a reasonable cost.

Introduction

Looking to convert your gas-guzzling car into an eco-friendly electric vehicle? One of the biggest factors to consider is the cost of the electric car battery, and whether it’s worth the investment. DIY electric car battery cost can vary depending on the size and range of the battery, the type of cells used, and whether you choose to buy new or used. On average, a DIY electric car battery can cost anywhere from $5,000 to $20,000, but can be higher if you opt for premium materials or professional installation.

However, it’s important to weigh this cost against the long-term savings and environmental benefits of driving a zero-emission car. With rising gas prices and a growing consciousness around sustainability, the DIY electric car battery has become an increasingly popular choice for those looking to reduce their carbon footprint.

Why DIY Electric Car Battery Cost Matters

When it comes to purchasing or building an electric car, the cost of the battery is a major factor to consider. The DIY electric car battery cost matters because it can significantly impact the overall cost of the vehicle and determine its affordability for many consumers. Besides, the cost of the battery is a significant component that affects many aspects of the electric car, such as its range, performance, and safety.

Therefore, understanding how much a DIY electric car battery cost can help consumers make informed decisions on whether to buy or build an electric car, and ensure they are getting the best value for money. In this blog section, we will explore the reason why it’s essential to consider the DIY electric car battery cost.

Benefits of DIY

As humans, we are wired to seek out satisfaction from our accomplishments. DIY (Do-It-Yourself) projects, regardless of the scale, provide a sense of achievement that has a positive impact on our lives both mentally and physically. Not only do we get a sense of pride and ownership from completing a project, but we also save money, learn new skills, and have fun in the process.

DIY projects can range from something as simple as fixing a leaking faucet to something as complex as building a treehouse. Whatever your skill level may be, there is always something that you can learn and improve upon. By taking the time to learn and invest in your projects, you can create something truly unique and personally rewarding.

So don’t be afraid to roll up your sleeves and try your hand at a DIY project, you might just surprise yourself with what you are capable of achieving.

Research on DIY Electric Car Battery Costs

Are you thinking of converting your gas-guzzling car into an environmentally friendly electric vehicle? Well, one of the most significant costs you’ll need to consider is the battery. Research has shown that the cost of a DIY electric car battery can range anywhere from $7,000 to $20,000, depending on the size and type of battery you choose. However, the good news is that the price of batteries has been steadily dropping over the years, with an estimated 60% decrease in cost since 20

One of the reasons for this drastic decrease in cost is the advancement of technology, which has led to the development of cheaper and more efficient battery chemistries. Additionally, the rise in demand for electric vehicles has led to increased competition among battery manufacturers, resulting in cheaper prices. When deciding on a battery for your DIY electric car, it’s essential to factor in the cost, weight, and performance.

Lithium-ion batteries are currently the most popular choice due to their lightweight and high energy density. However, they are also the most expensive, so it may be worth considering other battery technologies like lead-acid batteries for a lower-cost option. In conclusion, while the cost of a DIY electric car battery may seem daunting at first, the decreased price and advanced technology have made it more accessible than ever before.

Proper research and consideration of factors like cost, weight, and performance will help you choose the best battery for your DIY electric car.

Average Cost of Lithium-Ion Batteries

If you’re thinking about building your own electric car, one of the biggest costs you’ll face is the battery. Lithium-ion batteries are currently the most popular choice for electric vehicles, and the average cost of these batteries has been steadily decreasing over the years, making them a more affordable option for DIY enthusiasts. In fact, a recent study found that the average cost of lithium-ion batteries has dropped by over 80% since 20

This is great news for those looking to build their own electric car, as it means that the cost of the battery is becoming more and more manageable. Of course, the exact cost of the battery will depend on a number of factors, such as the size and capacity of the battery, as well as where you source it from. However, with prices continuing to decrease, there has never been a better time to consider DIY electric car battery costs.

Comparing DIY Costs vs. Commercially Available Batteries

When it comes to electric car batteries, DIY projects can be a tempting option for those looking to save money. However, research shows that the costs of building your own battery can quickly add up, and may even exceed the price of commercially available batteries. This is because constructing a battery from scratch requires specialized materials, tools, and expertise that can drive up costs.

Additionally, DIY batteries may not have the same level of reliability or performance as commercially available options, which can lead to greater long-term expenses and safety concerns. Ultimately, while building your own battery may seem like a cost-effective solution, in reality, it may not be the most practical or affordable option in the long run. It is important to carefully weigh the pros and cons before embarking on any DIY electric car battery projects.

Factors that Affect DIY Electric Car Battery Costs

DIY Electric Car Battery Costs When it comes to building your own electric car, battery costs can vary greatly depending on a number of factors. One of the main factors is the type of battery cells you choose to use. There are various types of cells available on the market, ranging from nickel-metal hydride (NiMH) to lithium-ion (Li-ion).

While NiMH batteries may be cheaper in the short term, they are generally less efficient and will likely need to be replaced more often. Li-ion batteries, on the other hand, are more expensive upfront but offer higher energy density and longer lifespan. Another factor to consider is the capacity of the battery pack, which will affect the overall size and weight of the car.

The more cells required, the higher the cost. Other considerations include the sourcing of materials, the complexity of the build, and the inclusion of any additional features, such as battery management systems. All of these factors will influence the final cost of a DIY electric car battery, but with careful planning and research, it is possible to build a high-quality and cost-effective battery pack.

DIY Electric Car Battery Cost Breakdown

DIY electric car battery cost can vary depending on the type of battery, its size, and the number of cells needed. Generally, the most commonly used battery for DIY electric cars is the lithium-ion battery, which has an average cost of around $200-$300 per kWh. The size of the battery will depend on the required range of the car, with a typical electric car battery using around 10-15 kWh.

However, larger batteries with a capacity of 100 kWh and above can cost upwards of $15,000. It’s also important to factor in the cost of additional components such as battery management systems, wiring, and chargers, which can add an additional $2,000-$4,000 to the total cost. Overall, DIY electric car battery cost breakdowns show that building your own electric car can be both cost-effective and rewarding, especially for those with a passion for DIY projects.

Materials List

If you’re interested in building your own electric car, one of the biggest factors to consider is the cost of the battery. The battery will likely be the most expensive component of the car. A typical electric car battery can cost anywhere from $5,000 to $20,000, depending on the size and type of battery you choose.

For example, a 24 kWh battery can cost around $6,000, while a 40 kWh battery can cost around $10,000. When building a DIY electric car, you have the option to either purchase a pre-built battery pack or assemble your own using individual cells. Assembling your own battery pack can be more cost-effective, although it does require more time and effort.

Overall, the cost of the battery will depend on your specific needs and budget.

Tools List

Are you considering building your own electric car, but are worried about the costs of the battery? Don’t fret, because we’ve got a DIY electric car battery cost breakdown just for you. The battery is arguably the most important component of an electric car, and it can also be the most expensive. However, with a little research and planning, you can bring down the cost significantly.

The main cost of building an electric car battery lies in the cells, and the number of cells you’ll need will depend on the voltage and range requirements of your car. You can choose between lithium-ion, nickel-metal hydride, or lead-acid cells, each with their own advantages and disadvantages. Lithium-ion cells are the most efficient and have the longest lifespan, but are also the most expensive.

Nickel-metal hydride cells are more affordable, but have a lower energy density. Lead-acid cells are the cheapest, but also the least efficient and heavier. Aside from the cells, you’ll also need a battery management system (BMS) to monitor the battery’s health and safety.

This is an essential component that will protect the battery from overcharging, over-discharging, and overheating. Depending on the size and complexity of your battery, a BMS can cost anywhere from a few hundred to a few thousand dollars. Other tools you’ll need for building the battery pack include a battery enclosure, wiring, thermal management system (cooling or heating), and safety equipment.

Don’t forget to include the cost of these components in your budget, as they can add up quickly. Overall, a DIY electric car battery can cost anywhere from $5,000 to $20,000, depending on the size, range, and type of cells used. While it may seem like a large investment, many electric car enthusiasts and builders see it as a worthwhile endeavor that can save money in the long run and offer a fun and sustainable mode of transportation.

Cost of Materials

When it comes to building your own electric car, one of the most significant costs will be the battery. The battery is the heart of the vehicle, providing the power needed to move the car forward, and it can be expensive. The cost of materials for a DIY electric car battery depends on the type of battery you choose to use.

Lithium-ion batteries are the most popular and expensive type of battery, with prices ranging from $300 to $500 per kWh. Lead-acid batteries are a more affordable option, ranging from $100 to $150 per kWh. However, they are heavier and less efficient than lithium-ion batteries.

When calculating the cost of your DIY electric car battery, it’s essential to consider the price of the battery, plus any additional components, such as a battery management system, wiring, and fuses. While it may be tempting to cut costs by opting for a cheaper battery, investing in a high-quality battery will pay off in the long run, providing you with better performance and longevity.

Tips for Reducing DIY Electric Car Battery Cost

If you’re considering building your own electric car, one of the biggest expenses you’ll likely face is the cost of the battery. Fortunately, there are several ways you can reduce the DIY electric car battery cost and save money without sacrificing quality or performance. One tip is to purchase a used battery.

This may sound daunting, but many electric car owners upgrade their batteries, meaning you can save money buying their slightly used one. Another way to cut costs is by purchasing individual battery cells rather than buying an entire pre-assembled battery pack. This allows you to customize your battery pack to meet your specific needs while also saving money.

Lastly, be sure to research multiple suppliers before making a purchase as prices can differ considerably. By following these tips, you can build a high-quality, cost-effective DIY electric car battery that will power your car for years to come.

Sourcing Batteries and Materials at a Lower Cost

Electric car DIY enthusiasts know that the battery system is one of the most significant expenses incurred. However, many productive techniques can be applied to reduce the cost of your battery or materials. Firstly, buying used batteries can be a great option since the technology brings little depreciation, and if you know how to refurbish them, you can save a considerable amount of money.

Another technique is to opt for a different type of cell for car batteries, like lithion ion, since it is becoming more affordable and offers high performance. Buying parts in bulk can also reduce costs since many retailers offer discounts for high-volume purchases. Comparing prices and looking for sales are also crucial in finding the best deals on materials.

Researching and exploring alternative sources like international retailers and ending auctions can also be worthwhile in finding bargains. Ultimately, creativity and resourcefulness can enable the reduction of expenses for DIY electric car building.

Optimizing Battery Configuration

When it comes to DIY electric car battery cost, optimizing the battery configuration can make a significant difference. One tip for reducing the cost is to use a battery pack with fewer, larger battery cells instead of many smaller cells. This can lower the cost per cell and reduce the complexity of the battery management system.

Another tip is to consider using second-hand batteries from electric vehicles that have reached the end of their life cycle. These batteries can still have a significant amount of usable capacity, and they can be acquired at a fraction of the cost of brand new cells. It’s important to keep in mind that safety should always be the top priority, so it’s crucial to work with reputable suppliers and to properly manage the battery system’s voltage and temperature.

By following these tips, you can significantly reduce your DIY electric car battery cost without compromising safety or performance.

Conclusion

In conclusion, deciding to build a DIY electric car may seem daunting at first, but with the increasing availability of affordable battery packs, the cost of entry has never been lower. While the initial investment may require some careful budgeting, the long-term savings on gas and maintenance costs make it a wise financial decision. Plus, who wouldn’t want to brag about their eco-friendly, custom-built ride at dinner parties? So, get ready to roll up your sleeves and start tinkering – the future is electric, and it’s DIY!”

FAQs

What is the average cost of building a DIY electric car battery?

The cost of building a DIY electric car battery varies depending on the size and type of battery, but it can range from $1,000 to $5,000.

Can I use recycled batteries to build a DIY electric car battery?

Yes, you can use recycled batteries to build a DIY electric car battery. This can significantly reduce the cost of building the battery.

Do I need any special tools to build a DIY electric car battery?

Yes, you will need some special tools such as a multimeter, soldering iron, and battery management system (BMS) to build a DIY electric car battery.

How long does it take to build a DIY electric car battery?

The time it takes to build a DIY electric car battery can vary depending on your level of experience, the size and complexity of the battery, and the availability of parts. It can take anywhere from a few days to several weeks to build a DIY electric car battery.