Shocking Truth Revealed: The Recyclability of Electric Car Batteries

As we embrace the era of electric vehicles, it’s important to consider how we’ll recycle their batteries. After all, these batteries are a crucial component of the vehicles, providing the power that makes them run. But once they’re worn down and in need of replacement, what happens to them? While it may be tempting to simply discard them, that’s not the most environmentally friendly option.

So what’s the best way to recycle electric car batteries? Let’s explore the options.

Understanding Lithium-Ion Batteries

One of the most frequently asked questions regarding electric cars is whether or not their batteries are recyclable. The answer is yes! Lithium-ion batteries are currently the most common batteries used in electric cars and can be recycled at the end of their life cycle. Recycling these batteries has several advantages, including reducing the need for new battery materials, reducing the amount of waste that goes into landfills, and helping to conserve natural resources.

Recycling also helps to decrease the environmental impact of the production and disposal of batteries, such as the release of toxic chemicals. It’s important to note that while recycling has its benefits, prevention is always the best solution. That means maximizing the lifespan of batteries, using them for other purposes after they’ve served their original purpose, and properly disposing of them when they can no longer be used.

By taking these steps, we can help to reduce our impact on the environment and ensure a sustainable future for generations to come.

Composition of Lithium-ion Batteries

Lithium-ion batteries are the most common type of rechargeable batteries found in everyday electronics, from smartphones to laptops. These batteries are made up of three primary components: a positive electrode, a negative electrode, and an electrolyte. The positive electrode, or cathode, is made of lithium cobalt oxide or lithium iron phosphate, while the negative electrode, or anode, is typically made of graphite.

The electrolyte is a liquid or gel that allows ions to flow between the electrodes. When the battery is charged, lithium ions move from the cathode to the anode, storing energy. When the battery is discharged, the process is reversed, allowing the stored energy to power devices.

Understanding the composition of lithium-ion batteries can help you make informed choices when it comes to using and recycling these common power sources.

Shelf Life of Lithium-ion Batteries

Lithium-ion batteries have become a part and parcel of our daily lives. From smartphones to laptops, electric cars, and even power banks, they are used extensively. But have you ever thought about their shelf life? Lithium-ion batteries’ lifespan usually depends on various factors such as temperature, usage, and storage.

The general consensus is that the batteries can last up to two to three years with normal usage. However, it can vary depending on how you take care of them. For instance, storing them at high temperatures can reduce their lifespan significantly.

On the other hand, charging them to 100% can also affect their longevity. In short, understanding the science behind lithium-ion batteries is crucial to maximize their shelf life. By taking proper care of them, you can not only save money but also prolong their lifespan.

Recycling Process for Lithium-Ion Batteries

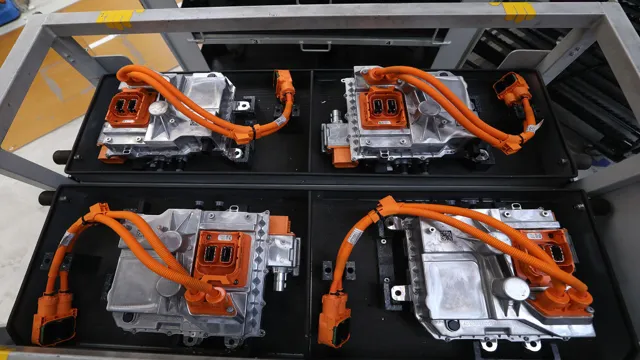

Yes, batteries for electric cars are recyclable, and recycling lithium-ion batteries is a complex process that requires specialized equipment and skilled workers. The process begins with the removal of any hazardous materials from the battery, such as electrolytes, before the battery is dismantled into its component parts. These parts include the electrodes, electrolyte solution, separating membranes, and casing materials.

From there, various chemical and mechanical techniques are used to separate and recover the valuable metals, such as cobalt, nickel, and lithium, contained within the battery. These recovered materials can then be used in the production of new batteries or other products. It is important to note that recycling lithium-ion batteries is not only environmentally responsible but also economically advantageous as it reduces the demand for finite resources and lowers the cost of raw materials for producing new batteries.

So, the next time you’re considering an electric car, remember that its battery is recyclable, and it’s just another way to help reduce your carbon footprint!

Collection and Transportation of Batteries

The collection and transportation of lithium-ion batteries is a crucial step in the recycling process. It’s important to handle them with care to prevent any possible damage or leakage of hazardous substances. This process typically involves specialized companies that have the necessary equipment and expertise to handle these batteries safely.

They use various methods to collect and transport the batteries, including specialized containers and trucks equipped with safety features. These measures ensure the safe transport and handling of batteries and reduce the risk of any potential harm to the workers, public, or the environment. Once collected, the batteries are transported to facilities where they are sorted and undergo the battery recycling process.

By ensuring proper collection and transportation of batteries, we can help protect the environment and promote sustainable practices.

Disassembly of Batteries

As we become increasingly reliant on our electronic devices, the issue of how to dispose of lithium-ion batteries is becoming more pressing. Luckily, there is a process for recycling these batteries that can greatly reduce their environmental impact. First, the batteries are disassembled, and their various components are sorted into different categories.

The lithium-ion cells are then separated from their protective covers and shredded into smaller pieces. These pieces are then soaked in a chemical solution to separate the valuable metals such as cobalt, nickel, and lithium from the other materials like plastic and copper. These metals can then be used to create new batteries or other electronic components.

By recycling lithium-ion batteries, we can reduce the amount of toxic waste that ends up in landfills and protect our environment for future generations.

Separation and Sorting of Battery Components

When it comes to recycling lithium-ion batteries, separation and sorting of the battery components is a crucial step in the process. This involves separating the different materials that make up a battery, such as the lithium cobalt oxide cathode, graphite anode, and electrolyte solution. One of the methods used for separation is mechanical shredding, which breaks down the battery into smaller pieces, making it easier to remove the different components.

After separation, the materials are sorted and processed based on their chemical composition. This allows for more efficient recycling since each material requires different processes for recovery. With the increasing demand for electric vehicles and portable electronics, it is essential to have an effective recycling process in place to reduce waste and conserve resources.

By separating and sorting the components of lithium-ion batteries, valuable materials can be recovered and reused, while reducing the environmental impact associated with battery disposal.

Challenges and Solutions

If you’re wondering, “Are batteries for electric cars recyclable?”, the short answer is yes! But, like any recycling process, it’s not without its challenges. Electric car batteries are typically made from a combination of metals, including lithium, cobalt, and nickel. Recycling these materials is essential for reducing waste and conserving natural resources.

However, the process can be difficult and expensive. For example, the extraction and separation of materials can be energy-intensive, and recycling facilities must utilize specialized equipment to safely handle the hazardous components of a battery. Despite these hurdles, many manufacturers are committed to promoting sustainable practices and investing in research to improve battery recycling.

As we continue to transition towards a more eco-friendly future, it’s crucial to prioritize responsible end-of-life management for electric car batteries.

Safety Concerns in Recycling Batteries

Recycling batteries is a critical process that reduces the amount of electronic waste and helps protect our environment. However, safety concerns arise when recycling batteries due to the potential for chemical leaks and explosions. The high flammability of lithium batteries poses a particular risk, and any mishandling during the recycling process puts operators and the surrounding environment at risk.

Fortunately, various technological advancements have led to safer recycling processes. For example, recycling plants can use robotic sorting systems and advanced chemical analysis techniques to reduce the potential for human exposure to toxic materials. Additionally, safety training programs for workers can help minimize the risks involved in battery recycling processes.

By prioritizing safety protocols and embracing modern recycling technologies, we can continue to reap the environmental benefits of recycling batteries while minimizing risks to human health and the environment.

Innovations in Battery Recycling

In recent years, innovations in battery recycling have become increasingly important due to the growing concern of electronic waste and its impact on the environment. However, there are a number of challenges that have hindered progress in this field. Firstly, battery recycling is an expensive process that requires a lot of resources and specialized equipment.

Secondly, the process is often inefficient, resulting in low yields and a high amount of waste. Fortunately, there are solutions that can help address these challenges. One of the most promising innovations is a process called “hydrometallurgy,” which involves using chemical solutions to recover valuable metals from the batteries.

Other solutions include the development of new technologies and the use of automation to reduce the cost and complexity of the recycling process. While there is still much work to be done in this field, these innovations offer hope for a more sustainable and efficient battery recycling industry.

Conclusion

In conclusion, the answer to whether batteries for electric cars are recyclable is a resounding yes. However, it’s not as simple as popping them in the recycling bin with your soda cans. The process involves intricate and specialized techniques to extract valuable materials and minimize waste.

So, the next time you’re taking your electric car for a spin, remember that your battery is not only helping the environment but is also a valuable resource that can be repurposed for future use. Reduce, reuse, and recycle – electric vehicle-style!”

FAQs

Why is battery recycling important for electric cars?

Battery recycling is important for electric cars because these batteries are made up of valuable materials like lithium, cobalt, and nickel that can be reused. Recycling helps to reduce the amount of mining required for these materials, which in turn reduces the impact on land, water, and air.

Can all types of electric car batteries be recycled?

No, not all types of electric car batteries can be recycled. Lithium-ion batteries, which are commonly used in electric cars, can be recycled, but other types of batteries like lead-acid batteries are not as easy to recycle and can have harmful effects on the environment if not disposed of properly.

How are electric car batteries recycled?

Electric car batteries are first dismantled and then crushed into small pieces. The parts of the battery that can be reused, such as the electrodes, are separated out and processed for re-use. The remaining materials are then sent to a specialized recycling facility where they can be further processed for use in other products.

What happens to batteries when they are not recycled?

When batteries are not recycled, they can end up in landfills where they can release harmful chemicals and metals into the surrounding soil and water. This can cause pollution and harm to wildlife and humans who come into contact with these materials. It also wastes valuable resources that could otherwise be reused.