Is it Safe and Practical to Use Electrical Tape on Car Battery Cables? Find Out Now!

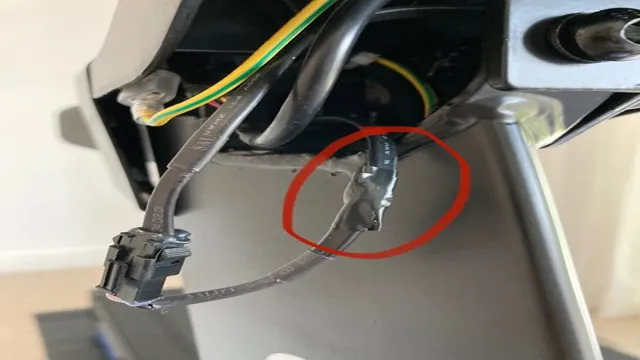

Is your car battery giving you a hard time? Do you need a quick fix to get your car moving again? Look no further than electrical tape! Yes, you read that right. Electrical tape can be a lifesaver when it comes to repairing car battery cables. When your car battery cables are corroded or have exposed wires, it can lead to a voltage drop, which can cause problems with starting your car.

Using electrical tape can help fix this issue in a pinch. It provides a barrier between the exposed wire and the car, preventing any electrical short circuits from occurring. But it’s important to note that electrical tape is only a temporary solution.

It won’t permanently fix the problem, so make sure to replace the cables as soon as possible. Also, be sure to wrap the tape tightly around the exposed area to ensure the best hold. So, next time you find yourself in a bind with your car battery, reach for the electrical tape and get yourself back on the road.

Just remember, it’s only a temporary fix, but it can definitely save the day.

Understanding the Risks

If you’re wondering whether to use electrical tape on a car battery cable, the simple answer is no, it’s not a safe solution. Electrical tape is designed for short-term repairs and can deteriorate over time due to heat, moisture, and other environmental factors. This can result in the tape coming loose or breaking down, potentially causing a short circuit or electrical shock.

Additionally, putting tape on a car battery cable will only cause a temporary fix, while the actual issue still persists. The best solution is to have a professional mechanic repair the cable or replace it entirely. It might cost a bit more, but it’s worth the investment to ensure your own safety while driving.

Remember, when it comes to electrical repairs on your car, always put safety first.

Corrosion and Damage to the Cable

Corrosion is a major concern when it comes to cable damage. Over time, cables can corrode due to exposure to moisture, salt, and other harsh conditions, which can weaken the cable and lead to failure. This makes it essential to understand the risks associated with corrosion and take proactive measures to prevent it from happening.

One effective way is to use anti-corrosion coatings on cables to protect them from environmental hazards. Additionally, regular inspections and maintenance can identify any signs of damage early on, allowing for prompt repairs that can prevent total cable failure. It’s essential never to underestimate the impact of corrosion on the lifespan and reliability of cables, as it can result in significant costs and even safety hazards.

By taking necessary steps to prevent corrosion and damage, you can help ensure that cables withstand the test of time and maintain their structural integrity.

Fire Hazard

Fire hazards are a significant concern for homeowners and businesses alike. Understanding the risks associated with fire is essential to prevent costly and often catastrophic damage. A fire can ignite from a variety of sources, including cooking equipment, electrical devices, smoking materials, and flammable liquids.

It’s crucial to keep flammable materials away from heat sources, such as stoves and heaters, and never leave cooking food unattended. Equipment should be maintained regularly to ensure it’s in good working condition and free from electrical faults. Additionally, smoking should be prohibited inside living spaces, and there should always be adequate ventilation in areas where flammable liquids are stored.

By taking these precautions, the risk of fire can be reduced, and you can feel safe and secure in your home or workplace.

Short Circuits

Short circuits can pose serious risks to your safety and property. Understanding these risks is important in preventing accidents that could lead to injury, fire, or damage. A short circuit happens when an electrical circuit, which carries electrical currents, encounters a low resistance path that causes an excess flow of current.

This can result in overheating, possibly leading to a fire or explosion. Short circuits can occur for many reasons, including wiring issues, damaged appliances or electrical systems, or even just a loose wire. It’s crucial to have a qualified electrician fix any problems as soon as possible to reduce the risk of a short circuit occurring.

Always take care around electrical circuits and appliances, avoid overloading systems, and never attempt to fix electrical problems unless you are trained and qualified. By staying vigilant and proactive, you can ensure the safety of yourself and those around you.

Alternatives to Electrical Tape

While electrical tape may seem like an easy solution for repairing car battery cables, it might not be the best option. Electrical tape is not designed to withstand the harsh conditions under the hood of a car. Heat, oil, and other fluids can cause the adhesive to deteriorate, compromising the electrical connection and potentially causing a dangerous situation.

Instead, consider using heat-shrink tubing or wire connectors to protect and repair the cables. These materials provide a stronger and more durable seal, ensuring that your car’s electrical system performs optimally and safely. So, to answer the question “Can I use electrical tape on a car battery cable?” – while it may work temporarily, it is not recommended for long-term use.

Heat Shrink Tubing

Heat shrink tubing is a wonderful alternative to electrical tape when it comes to securing and insulating wires. It is easy to install, lightweight, and highly durable, making it a great option for both DIY enthusiasts and professional electricians. Unlike electrical tape, heat shrink tubing doesn’t leave a sticky residue and provides a tight, waterproof seal that keeps the wires safe from moisture, heat, and corrosion.

Plus, it comes in various sizes and colors, making it possible to match the tubing to your wiring needs. Another benefit of heat shrink tubing is that it is resistant to solvents, chemicals, and UV rays, which gives it a longer lifespan than electrical tape. Overall, heat shrink tubing is an excellent choice for anyone looking for a reliable and long-lasting solution to securing wires.

Liquid Electrical Tape

Electrical Tape Electrical tape is a versatile tool used by many DIYers and professionals alike. However, it does have its limitations. One alternative to traditional electrical tape is liquid electrical tape.

This product is a rubber coating that is applied to wires or other electrical connections to provide insulation and protection against moisture, corrosion, and other potential hazards. Liquid electrical tape can be a great option for hard-to-reach areas or when traditional tape may not provide a secure enough seal. Additionally, liquid electrical tape is often more durable and longer-lasting than regular tape, making it a more reliable choice for long-term projects.

The next time you need to insulate or protect your electrical connections, consider trying out liquid electrical tape as an alternative to traditional tape.

How to Apply Electrical Tape Safely

If you’re wondering whether you can use electrical tape on a car battery cable, the answer is yes, but there are some precautions you should take. First, make sure the area is clean and dry before applying the tape. This will ensure that the tape adheres properly and doesn’t come loose over time.

Additionally, it’s important to only use electrical tape that is approved for use on car battery cables and meets safety standards. Using the wrong type of tape can result in damage to your car’s electrical system or even pose a safety hazard. When applying the tape, make sure to wrap it tightly and evenly, covering any exposed wires or damaged areas.

And remember, electrical tape is a temporary solution, so it’s best to have any damaged cables repaired or replaced as soon as possible to ensure your car’s safety and reliability on the road.

Preparing the Surface

Electrical Tape If you’re planning to use electrical tape for any DIY project, it’s essential to prepare the surface properly. Before applying the tape, make sure the surface is clean and dry. Any dirt or moisture can severely affect the adhesive properties of the tape.

You don’t want to end up with a weak or ineffective seal. If necessary, wipe down the surface with a clean cloth and let it dry completely. Once you’ve prepared the surface, you’re ready to apply the electrical tape safely.

Start by positioning the tape carefully, making sure it covers the area you want to protect. Press down firmly on the tape to ensure it adheres correctly. Continue wrapping the tape around the object, smoothing it out as you go.

Take your time and be patient during this process, as it can be frustrating when the tape doesn’t want to stick. Remember to stretch the tape gently as you wrap it, but don’t pull it too tight, as it could cause the tape to tear. With the right preparation and application, electrical tape can be an excellent way to protect your electrical connections and keep them safe from damage.

Wrapping the Tape

When working with electrical devices, it’s crucial to know how to use electrical tape correctly. Here’s how to wrap it safely: first, ensure that the surface you’re working with is clean and dry. Next, cut off a piece of electrical tape, making sure it’s longer than the area you need to wrap.

Begin wrapping the tape, ensuring that it overlaps with each rotation until the entire area is covered. Make sure to press the tape down firmly to prevent any possible electrical shock. It’s also crucial to know the color coding of electrical tape, as each color represents a specific voltage level.

For example, black tape is suitable for low voltage applications, while red tape is used for higher voltage levels. Emphasize safety and always follow instructions carefully when handling electrical equipment. By wrapping the tape correctly, you decrease the risk of damage or injury and ensure smooth operation.

So make sure to account for all safety measures when working with electricity, and use electrical tape responsibly.

Conclusion

In conclusion, while using electrical tape on car battery cables may seem like a quick fix, it is not a long-term solution. The tape may deteriorate over time due to exposure to heat and chemicals from the battery, which can lead to unsafe conditions. It is always best to replace damaged cables with new ones and ensure your vehicle’s electrical system is functioning properly.

Remember, shortcuts may save time, but they can’t always save your car.”

FAQs

Is it safe to use electrical tape on a car battery cable?

While electrical tape can provide a temporary fix for a damaged car battery cable, it is not a long-term solution. It is best to have the cable properly repaired or replaced for optimal safety.

Can electrical tape prevent corrosion on car battery cables?

No, electrical tape cannot prevent corrosion on car battery cables. Corrosion is caused by exposure to the elements and can be reduced by preventing moisture buildup and applying a corrosion-resistant coating or spray.

How long will electrical tape last on a car battery cable?

The lifespan of electrical tape on a car battery cable varies depending on usage, exposure to heat and other elements, and the quality of the tape. Generally, it is best to replace the tape and properly repair or replace the cable as soon as possible.

Can using electrical tape on a car battery cable cause electrical problems?

Yes, using electrical tape on a car battery cable can cause electrical problems if it is applied incorrectly or if it becomes damaged or worn over time. It is always best to have the cable properly repaired or replaced for optimal safety.