Unveiling the Truth: The Hidden Carbon Footprint of Electric Cars Battery Production

If you’ve been considering purchasing an electric vehicle (EV) as a more environmentally friendly option, you might have heard some buzz about the carbon dioxide (CO2) emissions from EV battery production. While it’s true that the manufacturing process of EV batteries does produce some carbon emissions, it’s essential to understand the bigger picture and context. After all, the goal of electrifying transportation is to reduce overall emissions from the transportation sector.

To understand the CO2 emissions from EV battery production, we must first consider the raw materials used to manufacture them. EV batteries require several minerals such as lithium, cobalt, and nickel, which are mined from ores. Mining and refining these minerals do generate some emissions, but the environmental impact is lower than fossil fuel extraction.

Additionally, as renewable energy sources become more prevalent in the electricity grid, the emissions from the mining process become less and less. Once the raw materials are extracted, they are transformed into usable battery cells. The manufacturing process of EV batteries does produce some CO2 emissions, but it’s becoming increasingly efficient, and many companies are focused on reducing it further.

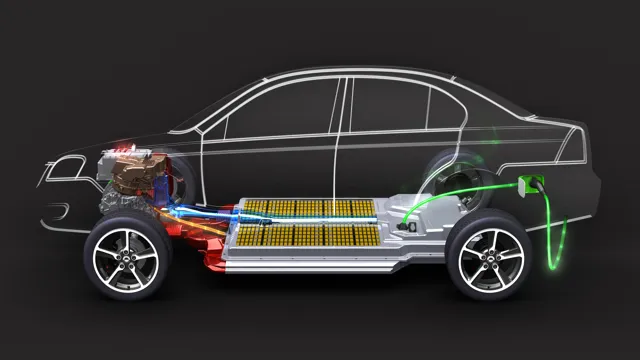

Additionally, as the demand for electric vehicles grows, the scale of production will increase, leading to economies of scale and further reductions in emissions. Furthermore, it’s crucial to consider the overall lifetime emissions of an EV versus a traditional gasoline engine vehicle. According to studies, even when accounting for the CO2 emissions from battery production, an electric vehicle has lower lifetime emissions than a conventional vehicle.

This significant reduction in emissions is due to the use of renewable energy in the electricity grid and the absence of tailpipe emissions. In conclusion, while EV battery production does produce some CO2 emissions, it’s essential to look at the bigger picture. Electrifying transportation is a crucial step towards reducing overall emissions from the transportation sector, and EVs offer a more sustainable option.

By using renewable energy sources in the electricity grid and reducing emissions from battery production, we can continue to move toward a more sustainable future.

Introduction

When it comes to electric cars, one of the common misconceptions is that they emit zero CO2 emissions. While it is true that electric cars produce significantly lower emissions than gasoline-powered vehicles, the production of their batteries is not entirely emission-free. The production process of electric car batteries involves mining and refining of raw materials, including lithium, cobalt, and nickel.

These processes emit a considerable amount of CO2 emissions, which contribute to the overall carbon footprint of electric cars. However, it is worth noting that the CO2 emissions from electric car battery production are significantly lower than those from the production of traditional gasoline cars. Additionally, efforts are being made to improve the sustainability of battery production by finding cleaner alternatives and optimizing the production process to reduce emissions.

What are EV batteries made of?

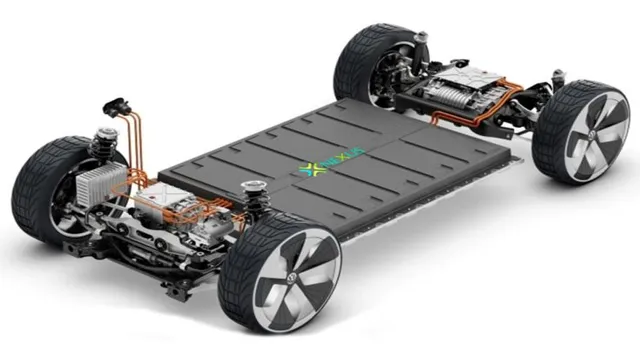

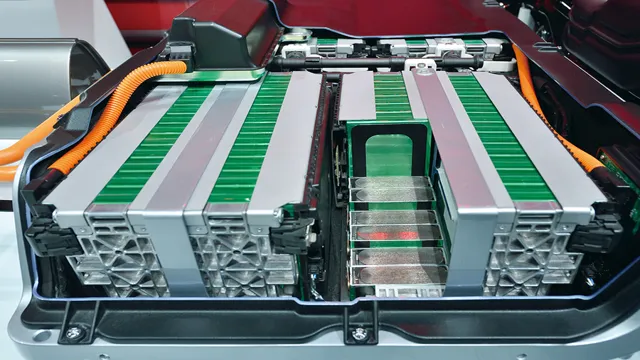

Electric vehicle (EV) batteries are one of the most significant components of any electric car. EV batteries are made of lithium-ion, which consists of several materials such as lithium, cobalt, nickel, and manganese. The composition of the battery may vary depending on the manufacturer, but the use of lithium-ion technology is relatively standard for most electric vehicles.

Overall, lithium-ion batteries are highly sought after in the electric vehicle industry due to their high energy density, low self-discharge rate, and long life cycle. In this article, we’ll explore the different materials that are used to make EV batteries and how they contribute to the overall performance of electric cars.

Why are CO2 emissions from battery production important to consider?

CO2 emissions from battery production Introduction: With the growing demand for electric vehicles and renewable energy storage systems, the production of batteries to power these devices has become an integral part of our daily lives. However, the process of producing these batteries has significant environmental consequences, including CO2 emissions and other contaminants. Therefore, it is essential to consider CO2 emissions from battery production, causing environmental destruction.

This blog aims to delve deeper into why CO2 emissions from battery production are crucial to consider and understand the impact of battery production on our planet.

CO2 emissions from EV battery production

Many people believe that driving an electric car is good for the environment but what about the CO2 emissions from producing the batteries? The reality is that it takes a lot of energy to mine, refine, and manufacture battery components, resulting in significant CO2 emissions. However, it’s important to note that despite these emissions, electric cars still have a much smaller carbon footprint compared to traditional gasoline-powered vehicles over their lifetime. In fact, studies have shown that an electric car produces just 30% of the CO2 emissions of a gasoline-powered car over its lifetime, even factoring in battery production.

Additionally, as renewable energy becomes increasingly common, the carbon footprint of electric car battery production is expected to further decrease in the coming years. So while it’s true that there are CO2 emissions involved in electric car battery production, the emissions are relatively small when compared to the benefits of a cleaner, more sustainable mode of transportation.

How is electricity generated for battery production?

Electricity, CO2 emissions, EV battery production Generating electricity for EV battery production requires a lot of energy, and this can result in CO2 emissions. Depending on the energy source used to generate the electricity, the emissions can vary. If renewable energy sources, such as solar or wind power, are used, the emissions will be lower.

However, if fossil fuels, such as coal or natural gas, are used, the emissions can be significant. It’s important for battery manufacturers to consider the environmental impact of their production methods, and to strive for cleaner and more sustainable methods of energy production. By reducing the emissions associated with EV battery production, we can help to make electric vehicles a truly eco-friendly transportation option.

What are the CO2 emissions from battery production?

CO2 emissions, battery production, EV CO2 emissions from EV battery production can vary depending on several factors, such as the type of battery, the materials used, and the location of the production facility. Generally, however, the production of lithium-ion batteries – the most common type used in EVs – does result in CO2 emissions. This is because manufacturing processes involve the use of fossil fuels, electricity, and other resources that emit greenhouse gases.

The amount of CO2 emissions from battery production can be significant, but it is important to keep in mind that EVs produce much less CO2 over their lifetime than traditional gasoline vehicles. Additionally, efforts are being made to reduce the carbon footprint of battery production by using renewable energy sources and improving efficiency in manufacturing processes. So while CO2 emissions from battery production cannot be completely eliminated, steps are being taken to minimize their impact and make EVs more environmentally-friendly overall.

Comparison of CO2 emissions from EV battery production to conventional car production

CO2 emissions, EV battery production, conventional car production. When it comes to comparing the CO2 emissions from the production of electric vehicle (EV) batteries versus conventional car production, the results are clear. Studies have shown that the production of an EV battery releases more CO2 than the production of a conventional car battery.

However, it’s essential to note that this difference is negligible when considering the lifetime emissions of an EV versus a traditional gasoline-powered vehicle. In fact, over the lifetime of an EV, it will emit far less CO2 than its conventional counterpart due to its more efficient energy usage and the lack of emissions from its tailpipe. While initial production of an EV battery may release more CO2, in the long run, it’s ultimately the more sustainable choice for reducing overall carbon emissions.

Reducing CO2 emissions from EV battery production

As electric vehicles become increasingly popular, it’s important to address the CO2 emissions from EV battery production. While electric cars themselves produce fewer emissions than their gasoline counterparts, the production of their batteries has a significant environmental impact. There are several ways to reduce these emissions, including using more sustainable materials in battery production and adopting more efficient manufacturing processes.

For example, some companies are experimenting with using recycled materials in battery production, reducing the need for mining and reducing waste. Additionally, rethinking the way batteries are manufactured, such as reducing the energy required to produce them, can also have a positive impact on the environment. While there is still work to be done, it’s encouraging to see companies taking steps towards reducing CO2 emissions from electric car battery production.

Improving battery production efficiency

Electric vehicle (EV) battery production has been identified as a significant contributor to CO2 emissions. Therefore, reducing CO2 emissions from EV battery production is crucial. To improve battery production efficiency, manufacturers are exploring various ways to reduce carbon footprint.

One approach is to reduce the amount of energy used in the production process. For example, using renewable energy sources like wind and solar power to generate electricity for battery production can decrease the carbon footprint. Another strategy is to decrease the amount of raw materials used in the manufacturing process.

Recycling and reusing battery components can reduce the amount of waste generated, resulting in less energy consumption in the production process. Improving battery production efficiency not only reduces CO2 emissions, but it also decreases production costs, making it more accessible for consumers to switch to electric vehicles. By adopting these methods, we can make strides in reducing our carbon footprint and moving towards a sustainable future.

Increasing the use of renewable energy sources

Renewable energy sources are becoming more and more popular, as people strive to reduce their carbon footprint and mitigate the effects of climate change. One important aspect of renewable energy that often gets overlooked is the production of batteries for electric vehicles (EVs). These batteries are essential for powering EVs, but their production can have a significant impact on the environment.

By using renewable energy sources to produce these batteries, we can reduce the amount of CO2 emissions that are produced as a result. This is because renewable energy sources such as solar or wind power do not produce any greenhouse gases, unlike traditional energy sources like coal or natural gas. By increasing our use of renewable energy sources, we can help reduce CO2 emissions from EV battery production and protect the environment for future generations.

Conclusion

It turns out that the spark of inspiration that led us to embrace electric cars as a solution to reduce CO2 emissions may have overshadowed a critical element – the generation of CO2 emissions from battery production. While these towering CO2 emissions figures may make us feel a bit low, we must remember that electric cars still hold significant promise for reducing our carbon footprint, but manufacturers and policymakers alike must take steps to mitigate the emissions generated from battery production. So, let’s power up our creative juices and brainstorm ways to supercharge the production of electric car batteries with a green, emissions-free approach!”

FAQs

How much CO2 emissions are produced during the production of an electric car battery?

The amount of CO2 emissions produced during the production of an electric car battery can vary, but on average it is estimated to be around 150-200 kg CO2 per kWh of battery capacity.

How do CO2 emissions from electric car battery production compare to emissions from gasoline-powered cars?

The CO2 emissions from electric car battery production are higher than the emissions from gasoline-powered cars during the production phase. However, over the lifetime of the vehicle, electric cars produce significantly lower emissions.

Can CO2 emissions from electric car battery production be reduced?

Yes, CO2 emissions from electric car battery production can be reduced by using renewable energy sources in the production process and improving the efficiency of the production methods.

How do different types of batteries used in electric cars affect CO2 emissions during production?

Different types of batteries used in electric cars can affect CO2 emissions during production. For example, lithium-ion batteries have a higher CO2 footprint compared to nickel-metal hydride batteries. However, lithium-ion batteries offer higher energy density and are therefore more widely used.