Rev Up Your Ride with DIY Electric Car Battery Backup : A Cost-Effective Solution

Do you know that you can create your own electric car battery pack for a fraction of the cost of purchasing a new one? Yes, you heard that right! With the advancements in technology, creating a DIY electric car battery pack is becoming more accessible and cost-effective than ever before. Electric cars are becoming more popular as people strive to reduce their carbon footprint and save money on fuel. However, purchasing a new battery pack for an electric car can be expensive, costing thousands of dollars.

This is where a DIY electric car battery pack comes in handy, as it can save you a significant amount of money. Creating a DIY electric car battery pack may seem daunting, but it is an achievable task with the right tools, knowledge, and guidance. It involves choosing the right cells, configuring them, and assembling them into a pack.

An electric car battery pack is essentially a collection of cells that work together to power electric cars. These cells can either be purchased new or recycled from old laptops, power tools, and other electronics. DIY enthusiasts are successfully creating their own battery packs for their electric cars, and you could do the same too! In this article, we will dive deeper into the world of DIY electric car battery packs and provide you with all the information you need to create your own.

Stay tuned to discover how to save money and power your electric car with a DIY battery pack!

Why Build Your Own Battery Pack

Building your own diy electric car battery pack may seem daunting, but there are plenty of reasons why it’s worth considering. For starters, building your own battery pack allows you to have complete control over the process and can often save you money in the long run. Plus, it’s a great opportunity to learn more about how electric cars work and gain a better understanding of the technology involved.

Additionally, many commercially available battery packs are designed to fit specific car models, leaving little room for customization or upgrades. By building your own pack, you can tailor it to meet your specific needs and make adjustments as needed. Finally, from an environmental perspective, creating your own battery pack means that you can ensure that only high-quality, environmentally friendly components are used, giving you peace of mind that your car is as sustainable as possible.

So, if you have the time and energy to devote to the project, building your own diy electric car battery pack can offer countless benefits.

Cost Advantage

When it comes to building your own battery pack, one of the biggest advantages is the cost savings. Purchasing pre-made battery packs can be incredibly expensive, especially when you factor in the price of batteries, connectors, and other necessary components. By building your own battery pack, you have control over the quality of the materials you use and can save a significant amount of money in the process.

Plus, if you need multiple battery packs, the cost savings can really add up. Imagine being able to power your devices or equipment without breaking the bank – it’s definitely possible when you take the DIY approach to battery packs. So why waste money on pre-made battery packs when you can build your own and save some serious cash?

Tailored to Your Needs

If you’re in search of a reliable power source that can be tailored to your specific needs, then building your own battery pack might be the way to go. Why should you go through the trouble of building your own battery pack instead of just buying one off the shelf? For starters, off-the-shelf batteries often come with standardized specifications that may not fit your specific requirements. By building your own battery pack, you have complete control over the specifications, such as the voltage, capacity, and size, ensuring that it meets your needs precisely.

Additionally, building your own battery pack can save you money in the long run, as you can choose only the components you need and avoid paying for unnecessary features. So, if you’re looking for a power source that can be tailored to your needs, building your own battery pack might just be the way to go.

Sustainability & Environmental Impact

As the world shifts towards green energy and sustainability, building your own battery pack has become an increasingly popular and environmentally conscious option. By constructing your battery pack from scratch, you can ensure that it is built using materials that are ethically sourced and free from potentially harmful chemicals. Additionally, building your battery pack allows you to tailor it precisely to your needs, making it much more efficient than pre-built options.

Not only is building your battery pack more sustainable for the environment, but it can also save you money in the long run by reducing your reliance on conventional power sources. By taking control of your energy consumption, you are not only making a positive impact on the environment but also on your bank account. So why not give it a try and see how you can build a more sustainable future for yourself and the world around you?

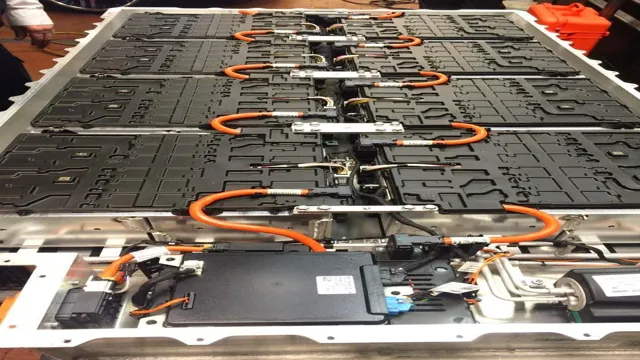

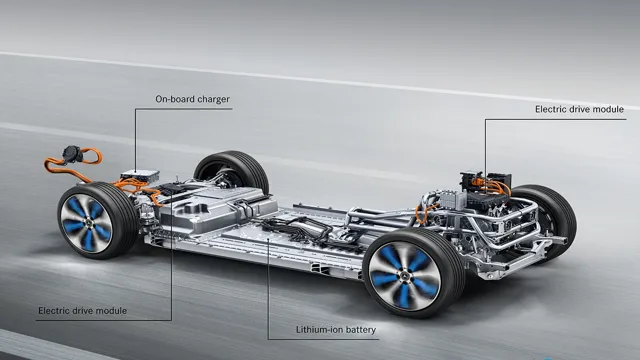

Components Needed for Building a DIY Battery Pack

Are you ready to take on the challenge of building your own DIY electric car battery pack? It’s a big task, but with the right components, you can do it! First and foremost, you will need high-quality lithium-ion cells, the heart of your battery pack. It is vital to choose cells with adequate capacity and discharge rate, as well as a reputable brand with strong safety standards. Additionally, you will need a battery management system (BMS) to monitor the cells’ performance and prevent overcharging or over-discharging.

Don’t forget about fuses, wires, and connectors – they might seem small, but they play a critical role in ensuring proper functioning and safety of your battery pack. Lastly, a high-quality battery charger is necessary to keep your battery pack charged. Remember, building a DIY electric car battery pack requires attention to detail and an understanding of electrical systems, so take the time to research and plan accordingly – the result will be worth it!

Battery Cells

When building a DIY battery pack, one of the most important components to consider is the battery cells. These can come in various shapes, sizes, and chemistries, and selecting the right one can make all the difference in the performance and longevity of your battery pack. Depending on your specific needs and budget, you can choose from lithium-ion, lithium-polymer, or even NiMH battery cells.

It’s important to make sure that the cells you choose are of high quality and from a reputable supplier, as low-quality cells can be dangerous and may even pose a fire hazard. Additionally, it’s important to ensure that the cells are matched in capacity and voltage to prevent any imbalances or issues with charging and discharging. By taking the time to carefully select and plan out your battery cells, you can create a reliable and efficient DIY battery pack that will meet your specific needs.

BMS (Battery Management System)

If you’re planning on building a DIY battery pack, then you will need a Battery Management System (BMS) to ensure the safety and longevity of your battery. A BMS is made up of several different components that work together to protect your battery from overcharging, over-discharging, and overheating. The first component you’ll need is the cell monitoring circuit, which measures the voltage and temperature of each individual cell within your battery pack.

This information is then sent to the second component, the control circuit, which determines when to charge and discharge each cell to maintain balance and prevent damage. Finally, the protection circuit is responsible for shutting down the battery in the event of a potential safety risk. With these components working together, you can ensure that your DIY battery pack is safe, efficient, and long-lasting.

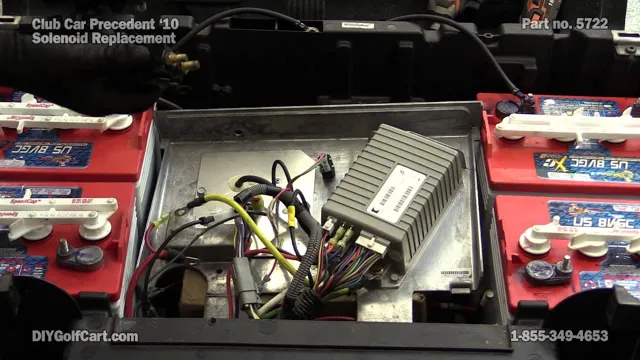

Wiring

When it comes to building your DIY battery pack, there are several components that you need to wire together before you can get started. Firstly, you’ll need a battery management system (BMS), which serves as the control center for your battery. It monitors the voltage, temperature, and current of the battery to keep it from overheating or overcharging.

Secondly, you’ll need to choose a wire size that can handle the amount of power your battery is going to produce. The larger the battery, the larger the wire size needs to be. You’ll also need to choose the connectors and terminals that you’ll use to connect your battery cells, wiring, and BMS together.

Finally, you’ll need to have a good understanding of battery safety and how to wire the components together correctly. Building a battery pack can be a challenging and rewarding project, but it’s important to do it safely and with the proper equipment.

Step by Step Guide to Building Your Own Electric Car Battery Pack

Building your own electric car battery pack may seem daunting, but with the right tools and knowledge, it can be a rewarding DIY project. First, you will need to choose the type of battery cells you will use. Lithium-ion cells are the most commonly used for electric cars due to their high energy density and longevity.

Next, you will need to plan out the layout of your battery pack and ensure that all the cells are connected in series for optimal performance. It’s important to consider factors like temperature regulation and safety features in your design to prevent potential hazards. Once your battery pack is assembled, it’s important to test it to ensure everything is working correctly.

With a little patience and attention to detail, building your own electric car battery pack can be a fulfilling and cost-effective venture for any DIY enthusiast.

Step 1: Choose Battery Cells

When it comes to building your own electric car battery pack, the first step is to choose the right battery cells for your needs. The choice of battery cells depends on various factors such as the range you desire, the weight and size of your vehicle, the charging time, and your budget. There are mainly three types of battery cells: Lithium-Ion (Li-ion), Nickel Metal Hydride (NiMH), and Lead-Acid.

Out of all these, Li-ion batteries are the most popular and energy dense as they provide a higher range and longer life as compared to NiMH and Lead-Acid batteries.

When choosing Li-ion battery cells, the most critical factors to consider are the cell’s energy density, cycle life, and safety features. Energy density measures how much energy a battery can store per unit of weight or volume, and cycle life counts the number of times a battery can be charged and discharged before it degrades.Furthermore, safety features such as overcharge and over-discharge protection, temperature control, and automatic shutdown, are essential considerations as these features will prevent internal damage and the chance of a battery fire. So, it’s vital to invest in high-quality and reliable battery cells that meet all the requirements of your electric car.

Step 2: Assemble Cells into Groups

Now that you have your cells sorted and tested, it’s time to assemble them into groups. This step is crucial as the grouping of cells directly affects the performance and overall lifespan of your electric car battery pack. It may seem simple, but it takes a bit of planning.

First, determine how many cells you need for your desired voltage and capacity. Then, arrange the cells in parallel and series connections to build modules. These modules are then connected to form the final battery pack.

Keep in mind that each module should be balanced in terms of voltage and capacity, so it’s best to use the same type and manufacturer of cells for each one. It’s also essential to monitor the temperature of each module and the overall battery pack during assembly to prevent overheating. By taking the time to properly assemble your battery pack, you can ensure optimal performance and safety while driving your electric car.

Step 3: Connecting the Cells

After preparing and testing the individual cells, it’s time to connect them to form the battery pack for your electric car. This process involves wiring and arrangement of the cells to achieve the desired voltage and capacity. The most common methods of connecting cells are series and parallel connections.

With series connection, cells are linked in a chain to increase voltage, whereas in parallel connection, cells are joined side-by-side to increase capacity. It’s crucial to follow the wiring diagram precisely, making sure that the cells are properly balanced with similar internal resistance. This helps to avoid overcharging, undercharging, or overheating of individual cells, which can cause significant damage to the battery and the electric car.

Once all the cells are safely connected, test the voltage and capacity of the battery pack again to ensure it meets the required specifications. Then, you can finally install the battery pack in your electric car and hit the road!

Step 4: Installing the BMS

Once you have all your battery cells connected, the next step is to install the battery management system (BMS). This is an essential component that monitors the voltage, temperature, and current of your battery pack. It ensures that your battery is working optimally and prevents damage and overheating.

Installing the BMS can be a bit tricky, but it’s not too difficult if you follow the instructions. First, you’ll need to mount the BMS on the battery pack. Make sure you secure it firmly so that it doesn’t move around.

Next, you’ll need to connect all the wires from the BMS to the battery cells. It’s important to follow the wiring diagram carefully to avoid any mistakes. Once everything is connected, test the BMS to ensure that it’s working correctly.

The BMS is a critical component of your electric vehicle, so it’s important to install it correctly to ensure a safe and reliable battery pack. Get this step right, and you’re one step closer to building your very own electric car!

Step 5: Wiring

Now that you’ve got your battery cells arranged in a desirable configuration, it’s time to wire them together to create your electric car battery pack. This step is crucial as it will ensure that your battery pack functions properly and provides the expected range and performance. Before starting the process, make sure to double-check the wiring diagram to avoid any mistakes.

Start by placing copper busbars or nickel strips on the cells’ ends and connecting them by welding or soldering. Then, place insulating material over the strips to prevent short-circuits. Once all the cells are connected, use a battery management system (BMS) to monitor and regulate the battery’s voltage, current, and temperature.

The BMS will also communicate with the car’s computer to ensure that it doesn’t overload the battery or cause any damage to it. By following these steps carefully, you can create a safe and efficient electric car battery pack that will power your vehicle for years to come.

Step 6: Final Checks and Testing

After assembling your electric car battery pack, the final step is to perform necessary checks and testing. This is a crucial step to ensure that your battery pack is working efficiently and safely. First, check the wiring connections to ensure that they are tight and secure.

Also, inspect the battery cells for any signs of damage or leaks. Use a voltage meter to check that each cell is within the designated voltage range. It’s also important to perform a balance test to ensure that each cell is working at the same level.

This can be done using a balance charger or a diagnostic tool. Finally, test the entire battery pack to check that it’s charging and discharging properly, and that the voltage remains steady over time. Taking the time to thoroughly check and test your battery pack can help prevent future issues and ensure that your electric car runs smoothly and safely.

Safety Considerations When Building Your Own Battery Pack

If you’re planning to build your own battery pack for a DIY electric car, there are some essential safety considerations to keep in mind. First off, it’s crucial to choose the right battery chemistries and technologies for your specific needs. Some batteries are more prone to thermal runaway and overcharging than others, and you don’t want to take any risks with your safety or the reliability of your car’s power supply.

Secondly, you’ll need to invest in high-quality components and materials, such as sturdy battery holders, cell balancers, and thermal management systems. These will help prevent any electrical shorts or malfunctions that could cause a fire or damage your battery cells. Finally, make sure to follow all the recommended safety guidelines and procedures when assembling and testing your new battery pack.

This includes wearing protective gear, keeping your work area well-ventilated and well-lit, and using professional-grade testing equipment to ensure that your cells are properly charged and balanced. With the right safety precautions in place, you can enjoy the many benefits of building your own battery pack for an electric car, from saving money on expensive factory-made models to gaining greater control over your vehicle’s performance and range.

Avoid Short Circuits

When building your own battery pack, safety should be your top priority. One important consideration is to avoid short circuits. A short circuit occurs when a circuit’s current takes a path of least resistance, bypassing the intended load.

This can cause a high current flow and result in overheating, damage to the battery, and possibly even a fire. To avoid short circuits, ensure that the components used are properly connected and insulated. It’s also crucial to check for any loose connections or damaged wires.

Additionally, using a high-quality protection circuit can help prevent short circuits by monitoring the battery’s voltage and current and cutting off power if any abnormalities are detected. Overall, taking the necessary precautions to avoid short circuits can go a long way in ensuring a safe and functional battery pack.

Handling Battery Cells Carefully

When building your own battery pack, it is crucial to handle battery cells with care to ensure safety. One of the most important considerations is to avoid puncturing or damaging the cells, as this can cause leakage or explosion. Always store battery cells in a safe and stable manner, such as in a fire-resistant container.

When soldering the battery pack, use a low-temperature soldering iron and avoid overheating the cells. It’s also essential to use the correct battery management system that can prevent overcharging or discharging, and monitor the temperature and voltage levels to prevent potential hazards. Overall, taking proper precautions when handling battery cells can ensure the safety and longevity of your DIY battery pack.

Proper Tools and Equipment

When building your own battery pack, it is important to have the right tools and equipment to ensure safety and avoid accidents. Some of the essential tools include a soldering iron, wire strippers, heat shrink tubing, and a multimeter. These tools not only help with the overall construction process, but they also help in identifying and rectifying issues in the battery pack.

Safety should be a top priority when building a battery pack, so it is important to invest in quality equipment. Imagine trying to repair a car without the right tools, it would be a difficult and possibly dangerous task. Building a battery pack is no different; using the proper tools and equipment can be the difference between a safe and successful build, or a potentially dangerous one.

Final Thoughts

In conclusion, building a DIY electric car battery pack can be a daunting task, but it is also a rewarding one. It requires the right tools, knowledge, and patience to complete the project successfully. However, the benefits of having your own electric car are priceless.

Not only will you be reducing your impact on the environment, but you will also save money in the long run. Before embarking on this journey, it is important to do your research and understand the components involved. You will need to source high-quality batteries, have a deep understanding of electrical wiring, and be able to troubleshoot any issues that may arise.

With dedication and determination, building your own DIY electric car battery pack is possible and can lead to a more sustainable future.

Conclusion

In conclusion, creating a DIY electric car battery pack can be a fun and challenging project for the eco-conscious enthusiast. With a little bit of knowledge and elbow grease, anyone can convert their gas guzzling vehicle into a sleek, energy-efficient machine. Plus, every time you hit the road without emitting harmful pollutants, you can pat yourself on the back for being the ultimate DIY environmentalist.

“

FAQs

What are the advantages of DIY electric car battery pack?

DIY electric car battery pack offers cost savings and customization options compared to pre-built battery packs. Additionally, it can be a fun DIY project for car enthusiasts.

Can I use any type of battery for a DIY electric car battery pack?

No, not all batteries are suitable for a DIY electric car battery pack. Lithium-ion batteries are the most commonly used type of battery due to their high energy density and low weight.

How do I know if my DIY electric car battery pack is safe?

Safety should be a top priority when building a DIY electric car battery pack. Ensure that the pack has proper insulation, overcharge/over-discharge protection, and is never exposed to high temperatures or punctures.

Is it possible to improve the performance of a DIY electric car battery pack?

Yes, there are various ways to improve the performance of a DIY electric car battery pack, such as increasing the number of cells or using higher quality cells with better energy density. However, it is important to ensure that the overall design of the battery pack is optimized for performance and safety.