Powering the Future: A Closer Look at Lithium Nickel Cobalt Aluminum Oxide Batteries for Electric Cars

As our world becomes increasingly concerned with the impact of fossil fuels on the environment, electric cars are rapidly gaining popularity. However, the true key to a cleaner future lies in the electric car batteries that power them. These amazing technological marvels are quietly working behind the scenes to revolutionize transportation, and their influence on our lives could be profound.

With their ability to reduce emissions, increase efficiency, and decrease our reliance on oil, electric car batteries may just be the key to a brighter tomorrow. So, if you’re looking to make a difference and get ahead of the curve, it’s time to start embracing the power of electric car batteries!

Understanding Lithium Nickel Cobalt Aluminum Oxide Batteries

Electric car batteries have come a long way in recent years, and one of the latest battery technologies that has caught the attention of car manufacturers is Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries. These batteries use a blend of lithium, nickel, cobalt and aluminum oxide to create a high-capacity energy storage unit that is compact and lighter than traditional batteries, making them perfect for use in electric cars. NCA batteries offer many benefits such as improved performance, higher energy density, and longer life span, which means electric cars powered by NCA batteries can achieve longer range and better acceleration, while also being more resilient and having a lower cost of ownership in the long run.

With the increasing demand for electric cars, it is likely that we will see more and more NCA batteries being used in the near future.

What are Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries?

Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries are a type of rechargeable battery typically used in high-performance devices such as electric vehicles and power tools. These batteries are known for their high energy density, meaning they can store a large amount of energy in a small space. They also have a long cycle life, meaning they can be charged and discharged many times without degrading.

Another advantage of NCA batteries is their ability to deliver high power output, making them perfect for applications that require a lot of energy in a short amount of time. However, they can be sensitive to high temperatures, and care should be taken to ensure they are used and stored within their recommended temperature range. Overall, Lithium Nickel Cobalt Aluminum Oxide batteries are an excellent choice for high-performance applications that require long-lasting, reliable power.

Advantages of NCA Batteries in Electric Vehicles

Lithium Nickel Cobalt Aluminum Oxide batteries, or NCA batteries, have become a popular choice for electric vehicles due to their numerous advantages. These batteries have a higher energy density than other types of lithium-ion batteries, which means they can store more energy in a smaller space. This translates into a longer driving range for electric vehicles.

Additionally, NCA batteries have a longer lifespan than other lithium-ion batteries, which means they will need to be replaced less frequently. They also have a faster charging time, allowing electric vehicle owners to spend less time waiting for their vehicle to recharge. Overall, NCA batteries offer an impressive combination of energy density, lifespan, and charging time, making them an excellent choice for electric vehicle manufacturers looking to improve their products.

Challenges in Manufacturing NCA Batteries

Manufacturing electric car batteries with lithium nickel cobalt aluminum oxide or NCA poses several challenges. One of the primary concerns is ensuring the safety of the manufacturing process and the end-product. NCA batteries are known to be volatile and prone to combustion if not carefully manufactured.

Another significant challenge is the availability of raw materials. The production of NCA batteries relies heavily on cobalt, which is in limited supply. This scarcity drives up the costs of production and can lead to supply chain disruptions.

Furthermore, the manufacturing process of NCA batteries requires a significantly higher level of expertise and precision than other battery types, which can increase overall production costs. It is essential to overcome these challenges to continue the growth of the electric vehicle industry and to ensure the sustainable future of energy consumption.

Issues with Material Costs and Availability

Manufacturing NCA batteries face a variety of challenges, including issues with material costs and availability. NCA batteries utilize nickel, cobalt, and aluminum, all of which are expensive and in high demand. The fluctuation in the prices of these materials can impact the overall cost of battery production, making it difficult to predict expenses and maintain competitiveness in the market.

Additionally, the availability of these materials can be limited, leading to delays or production shutdowns. This poses a significant risk to manufacturers relying on NCA batteries as their primary product. Despite these challenges, manufacturers are constantly searching for ways to reduce costs and increase efficiency, such as alternative material sourcing and advanced manufacturing processes.

With emerging technologies like electric vehicles and renewable energy storage relying heavily on NCA batteries, finding solutions to these challenges is vital for the future of the industry.

Difficulty in Scaling Up Production

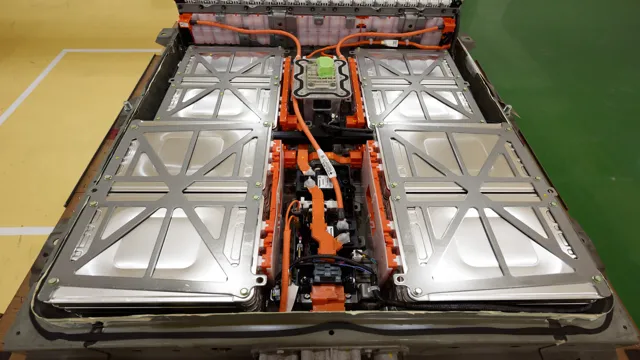

NCA batteries When it comes to scaling up production for NCA batteries, manufacturers face several challenges. One of the primary issues is ensuring consistency in the manufacturing process. Because these batteries require a precise combination of materials and manufacturing techniques, any variations or deviations can affect their overall performance and lifespan.

Additionally, producing NCA batteries on a large scale requires significant investment in specialized equipment and facilities. Even with that investment, it can still be difficult to achieve high volumes due to the complexity and intensity of the manufacturing process. As demand for these batteries continues to increase, manufacturers will need to find new and innovative ways to scale their production while maintaining the quality and consistency necessary for success.

Safety Concerns and Flammability

Challenges in Manufacturing NCA Batteries When it comes to manufacturing NCA batteries, safety concerns and flammability pose significant challenges. NCA batteries use a combination of nickel, cobalt, and aluminum, which make them highly efficient and energy-dense. However, the high energy density also makes NCA batteries prone to thermal runaway and bursting.

If the battery gets too hot or overcharged, it can lead to a catastrophic failure, causing fire or explosion. To minimize these risks, manufacturers have to implement stringent quality control measures during production, storage, and transportation. They also have to use advanced safety features such as thermal management systems, sensors, and protective casing to prevent thermal runaway or overcharging.

Despite these safety measures, NCA batteries still pose a significant challenge for manufacturers, and any manufacturing defect or oversight can have severe consequences. Keyword: NCA batteries

Future of Lithium Nickel Cobalt Aluminum Oxide Batteries

As the electric vehicle industry rapidly expands, engineers and researchers are continuously improving upon battery technology to make them more efficient and cost-effective. One promising option is the lithium nickel cobalt aluminum oxide battery, which provides a higher energy density compared to traditional lithium-ion batteries. This means that they can store more energy in a smaller space, making them ideal for use in electric cars, which require long-lasting batteries that don’t take up too much space.

Furthermore, this battery technology has the potential to enhance the range and acceleration of EVs while reducing their weight and overall cost. With ongoing research and development, it is likely that we will see more widespread use and further advances in lithium nickel cobalt aluminum oxide batteries in the near future.

Advances in Production Technology

Lithium Nickel Cobalt Aluminum Oxide Batteries (NCA Batteries) NCA batteries have the potential to revolutionize the energy storage industry due to their high energy density and longevity. However, they have been plagued by lifecycle issues, including capacity fading and safety concerns. Recent advances in production technology have significantly improved NCA battery performance and durability.

Anodized aluminum oxide coatings have been applied to NCA cathodes, providing improved structural stability and better resistance to degradation. Additionally, innovations in electrode production have increased the battery’s energy density and cycle life. These advancements have paved the way for NCA batteries to become a viable alternative to traditional lithium-ion batteries in electric vehicles, renewable energy storage, and handheld devices.

The future looks promising for NCA batteries as more research and development are devoted to improving their performance and reducing their costs, making them a viable and economical energy storage option.

Growing Market Opportunities for EVs

As the world shifts towards renewable energy, more and more people are considering electric vehicles as their mode of transportation. This has opened up a growing market for EVs, presenting new opportunities for car manufacturers and battery technology developers. Among the various battery technologies available, Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries have emerged as a promising solution for electric cars due to their high energy density, long lifespan, and rapid charging capabilities.

The future of NCA batteries looks bright as they continue to improve in performance and become more accessible to the mass market. With the demand for electric vehicles on the rise, it will be exciting to see how this technology evolves and shapes the future of transportation.

Conclusion: NCA Batteries are the Future of Electric Cars

In conclusion, the world of electric car batteries can be summed up as a mixture of lithium, nickel, cobalt, and aluminum oxide – a chemistry set for the environmentally conscious adult. But what’s truly remarkable about these batteries is not just their composition, but what they represent: a cleaner and more sustainable future for transportation. So, let’s raise a cheers to these little powerhouses of the electric car world, for they’re not just redefining the way we drive, but they’re paving the way for a greener tomorrow.

“

FAQs

What is lithium nickel cobalt aluminum oxide?

Lithium nickel cobalt aluminum oxide, or NCA, is a type of cathode material used in electric car batteries.

Which type of electric car battery is most commonly used?

Currently, lithium-ion batteries are the most commonly used type of electric car battery.

How do electric car batteries compare to traditional car batteries?

Electric car batteries are typically larger and have a higher energy density than traditional car batteries.

What is the average lifespan of an electric car battery?

The average lifespan of an electric car battery is typically around 8 to 10 years, though this can vary depending on usage and other factors.