Revving Up the Future: How the Electric Car Battery Circuit is Paving the Way for Sustainable Transportation

Have you ever wondered what makes electric cars so impressive, and how they manage to run on nothing but electricity? Well, it all comes down to the car battery circuitry. Understanding the circuitry of electric car batteries is essential if you want to get the most out of your electric vehicle. Not only will it help you better comprehend how the car works, but it will also help you maintain the batteries in tip-top condition, which is critical for longevity and safety.

In this article, we’ll dive into the intricate details of electric car battery circuitry, unraveling all the enigmas that surround this advancing and exciting technology. So hold on tight to your seatbelt and get ready for an electrifying ride!

How Electric Car Batteries Work

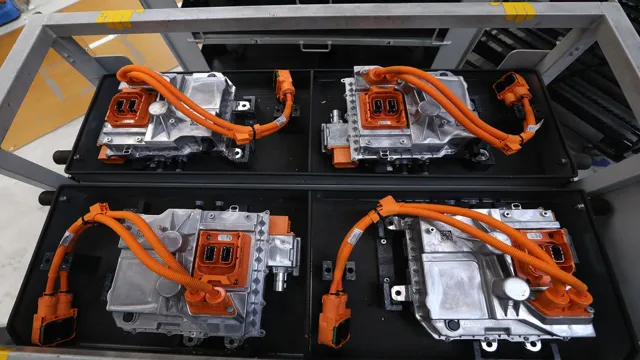

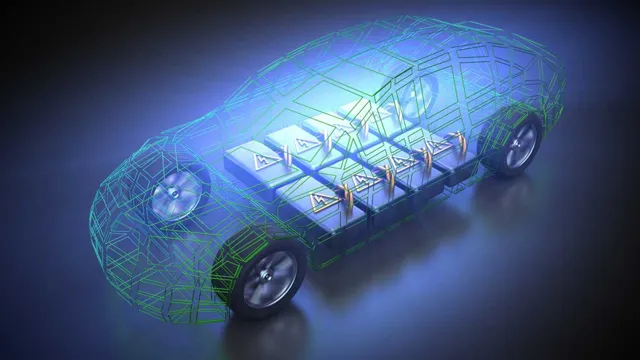

Electric car batteries work on a complex circuit that involves several components. At its core, the battery circuit consists of the battery pack, the power electronics module, and the electric motor. The battery pack stores the electrical energy needed to power the vehicle, and it contains several individual lithium-ion cells that are connected in series or parallel to create a higher voltage and capacity.

The power electronics module monitors the health of the battery pack, regulates the electrical current, and converts DC energy into AC energy. The electric motor, on the other hand, converts the electrical energy into mechanical power to drive the wheels. The battery circuit is a closed loop system that continually transfers energy between these components to maintain optimum performance and efficiency.

As electric vehicles become more popular, advances in technology are helping to improve battery capacity, reduce charging time, and increase the driving range of these vehicles. A well-designed electric car battery circuit is essential in ensuring the smooth operation of an electric vehicle, and it plays a crucial role in making electric cars a viable alternative to traditional gasoline-powered vehicles.

Exploring Lithium-Ion Batteries

Lithium-ion batteries are the backbone of electric cars, powering these eco-friendly vehicles to travel long distances with minimal emissions. Unlike traditional engines that burn fossil fuels, electric cars rely solely on their batteries to produce energy. So how do lithium-ion batteries work? It starts with the movement of lithium ions between two electrodes, the anode and cathode, housed in the battery.

When an electric current is applied, lithium ions move from the cathode to the anode, creating a flow of electrons that generate the energy needed to power the electric motor. The best part about these batteries is their ability to recharge, making them a sustainable power source for electric cars. With the help of regenerative braking, the battery can capture the energy that would typically be lost during braking and use it to recharge itself.

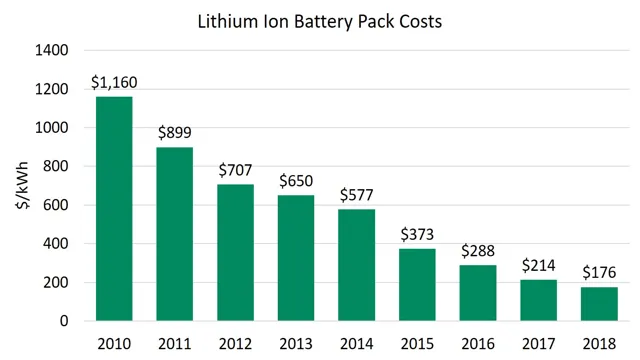

So, the next time you hear someone say that electric cars run on expensive batteries that need constant replacement, know that it’s just a myth. Lithium-ion batteries are designed to last, and with the advancements in technology, they are becoming even more efficient and affordable.

Examining Battery Management Systems

Electric car batteries are a key component of the vehicle’s power source, and they work by storing and delivering energy to power the electric motor. Battery management systems (BMS) play an integral role in the proper function and longevity of these batteries. They help to maintain the optimal temperature and state of charge of the battery cells, prevent overcharging and discharging, and provide real-time data on the battery’s performance.

Think of the BMS as the brain of the electric car battery system, ensuring that it operates efficiently and safely. Without the BMS, the battery cells could become damaged, which could result in reduced performance, shorter lifespan, or even safety risks. As the popularity of electric cars continues to grow, BMS technology is advancing to enhance the performance, efficiency, and safety of electric car batteries.

Circuit Design for Electric Car Batteries

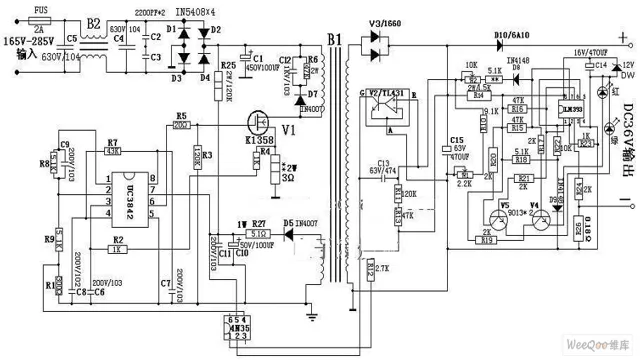

Designing a circuit for an electric car battery is a critical endeavor that requires advanced knowledge of electronics and battery technology. The circuit must regulate the electric current flowing from the battery to the motor while maintaining the battery’s health and safety. This is accomplished through a battery management system (BMS), which monitors the battery’s temperature, voltage, and state of charge.

The BMS regulates the flow of current to the motor, preventing overloads and overcharging, which can cause damage to the battery. In addition to the BMS, the circuit can also include safety mechanisms that protect against short circuits, overvoltage, and overheating. Designing an electric car battery circuit is a complex and meticulous process that must be executed with the utmost care to ensure the safe and efficient operation of the vehicle.

The Basics of Input and Output

When it comes to making circuit designs for electric car batteries, it’s important to understand the basics of input and output. Input refers to the energy being fed into the circuit, while output is the energy being produced by the circuit. In order to maximize the efficiency of the circuit, the input and output must be balanced.

This means that the input energy must be equal to the output energy, and the voltage and current must be matched accordingly. The circuit design also needs to take into account the specific requirements of the electric car battery, such as the voltage and amperage needed for charging and discharging. By carefully considering these factors, the circuit design can be optimized to ensure that the electric car battery operates at maximum efficiency and durability.

Voltage Regulators and DC to DC Converters

Electric car batteries present a unique challenge when it comes to circuit design. In order to effectively power the vehicle, voltage regulators and DC to DC converters are necessary. These devices work to regulate the voltage output from the battery in order to prevent damage to the car’s electrical components.

A voltage regulator essentially acts as a buffer between the battery and any devices connected to it, ensuring that the output stays within a safe range. DC to DC converters, on the other hand, are used to convert the battery’s DC voltage to a different level, such as stepping down from 48V to 12V. This is crucial in electric cars as various components require different levels of voltage to operate effectively.

By implementing these devices into the circuit design, electric car batteries can be utilized to their fullest potential, providing reliable and efficient power for the vehicle.

Protecting Against Overcharging and Overheating

Electric car batteries are a complex and critical component of electric vehicles that require careful circuit design to protect against overcharging and overheating. Overcharging can lead to premature battery ageing, reduced capacity, and even fires, while overheating can cause thermal runaway and explosion. To prevent these issues, electric car batteries require proper circuit design that can accurately monitor and control charging and discharging processes.

One critical aspect of circuit design for electric car batteries is the use of a battery management system (BMS), which can balance the charge and discharge rates of individual battery cells. A well-designed BMS can provide real-time monitoring of battery temperature, voltage, and current, and adjust the charging and discharging rates accordingly. Additionally, circuit design should incorporate safeguards such as temperature sensors, fuses, and thermal cutoff switches to prevent overcharging and overheating.

Together, these circuit design measures can ensure safe and efficient operation of electric car batteries, providing a reliable and sustainable alternative to fossil fuel-powered vehicles.

Maintenance and Repair of Electric Car Batteries

Electric car batteries are complex components with numerous circuits that need proper maintenance for optimal performance. The circuitry of an electric car battery is made up of the battery cells, the battery management system (BMS), and the power electronics. The BMS controls and manages the cells by ensuring that they are all charged similarly, preventing overcharging and undercharging, and also monitoring the temperature of the cells.

The power electronics, on the other hand, convert the DC power from the battery cells to AC power that can be used to power the electric car. Regular maintenance of the electric car battery circuitry is vital for maximum efficiency and safety. Proper maintenance can help to prevent circuit failures, which can lead to the battery becoming unsafe.

It is also essential to schedule routine maintenance checks to make sure that the BMS and power electronics continue to function correctly over time. By following these guidelines, electric car owners can extend their battery’s lifespan and enjoy a more reliable vehicle.

Common Battery Issues

Electric car batteries are a crucial component of electric vehicles and are responsible for supplying power to the vehicle’s electric motor. However, like any other battery, electric car batteries can suffer from common issues such as reduced performance and capacity over time. Regular maintenance and repair can help prolong the lifespan of electric car batteries and optimize their performance.

It’s crucial to keep the battery clean and free from dirt and debris, as dirt can cause corrosion and reduce battery life. Additionally, monitoring the battery’s state of charge can help prevent it from becoming overcharged or fully depleted, which can lead to irreversible damage. If you notice any significant performance issues with your electric car battery, it’s essential to seek professional repair immediately to prevent further damage and ensure optimal performance.

By taking proper care of your electric car battery, you can enjoy a smooth and efficient driving experience for many years to come. So, always give your electric vehicle battery a little extra love and attention, and it will undoubtedly repay you with smooth and efficient performance on the road.

Replacing a Battery Pack

When it comes to maintaining and repairing electric car batteries, replacing a battery pack is a task that may eventually become necessary. While the lifespan of an electric car battery can vary depending on the model and usage, it’s important to keep in mind that even the best batteries eventually wear out. One indication that a battery pack may be on its last leg is a noticeable reduction in driving range.

If you’re experiencing this issue, it’s important to have your battery checked by a professional to determine if replacement is necessary. Replacing a battery pack can be a daunting and pricey task, so it’s crucial to seek out a qualified technician with experience working on electric car batteries to ensure a safe and reliable replacement. Ultimately, investing in a new battery pack can potentially extend the lifespan of your electric car and keep you on the road for many more miles to come.

Innovations in Electric Car Battery Technology

When it comes to electric car batteries, advancements in technology are constantly being made. One innovation that has been gaining attention is the electric car battery circuit. A battery circuit is simply a series of connected batteries that work together to provide the power needed to run an electric car.

In the past, electric car batteries could be heavy and took up a lot of space. However, advancements in battery circuit technology have made the batteries smaller, lighter, and more efficient. This has allowed electric cars to travel longer distances and at faster speeds.

Additionally, battery circuit technology has allowed for improved safety features, such as temperature control and overcharging protection. As electric cars become more popular, innovations in battery circuit technology are sure to continue to improve and enhance the performance of these vehicles on the road.

Conclusion

In conclusion, the electric car battery circuit is not just a simple power source for your vehicle. It’s a complex web of interconnected components, each playing a crucial role in the efficiency and sustainability of your car. From the battery cells themselves, to the control module that manages power output, to the various sensors and safety features that keep you moving safely down the road, this circuit is nothing short of a technological marvel.

So the next time you plug in your electric car, take a moment to appreciate the incredible engineering behind that simple act. It truly is electric in every sense of the word.”

FAQs

What is an electric car battery circuit?

An electric car battery circuit is the system that allows electric charge to flow from the battery to power the car’s motor.

How long does an electric car battery circuit last?

The lifespan of an electric car battery circuit varies, but it typically lasts between 8 and 10 years or around 100,000 miles before needing to be replaced.

Can an electric car battery circuit be repaired?

In some cases, an electric car battery circuit can be repaired, but it typically depends on the extent of the damage. It may be more cost-effective to replace the entire circuit.

How does an electric car battery circuit differ from a traditional car battery system?

An electric car battery circuit relies solely on an electric charge to power the car, whereas a traditional car battery system uses a mixture of gasoline and electrical power to run the car.