Revolutionizing the Road: An In-Depth Look at Electric Car Battery Construction

Electric cars have become more popular, efficient, and affordable in recent years. However, many people are still not familiar with the technology behind these vehicles, especially their batteries. In this blog post, we will explore the construction of electric car batteries and how they differ from traditional gas-powered vehicles.

From the chemistry of the cells to the assembly process, we will cover the basics of how electric car batteries work and what makes them unique. So buckle up and join us for a ride into the world of electric car battery construction.

Overview of Electric Car Batteries

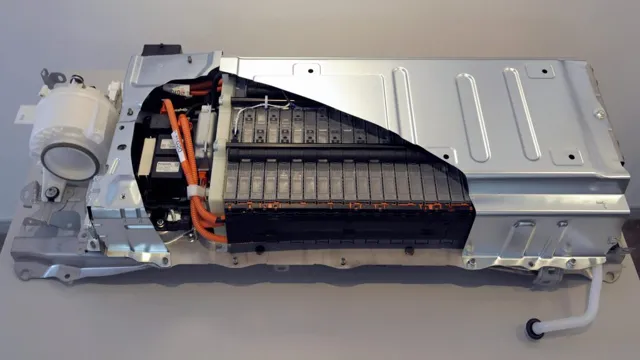

Electric car battery construction is a complex process that involves the use of various materials. Typically, these batteries are made up of lithium-ion cells, which store the energy needed to power the electric motor. Each cell contains electrodes, separators, and electrolytes, which work together to create a flow of electrons.

These cells are then grouped together to form larger modules that can be connected to create a full battery pack. The materials used to construct these batteries are carefully chosen to ensure they can withstand high temperatures, vibrations, and shock. Moreover, the exact construction of electric car batteries can vary depending on the manufacturer and vehicle model.

However, one thing remains constant: the importance of building durable and efficient batteries that can store and deliver power reliably for the long haul.

Types of Electric Car Batteries

Electric car batteries are a crucial component of electric vehicles. These batteries use chemical reactions to store electrical energy and power the car’s electric motor, making them an eco-friendly and cost-effective alternative to gas-powered vehicles. There are several types of electric car batteries, each with its own advantages and disadvantages.

Lithium-ion batteries are the most common type, known for their high energy density, long lifespan, and fast charging capabilities. Nickel-metal hydride batteries are also popular, especially in hybrid cars, due to their durability and reliability. However, they have a lower energy density and are bulkier compared to lithium-ion batteries.

Finally, solid-state batteries are a new and promising technology that is still in development. They offer even higher energy density and faster charging times than lithium-ion batteries, but are not yet widely available. Choosing the right type of electric car battery depends on various factors, such as cost, performance, and availability, and will ultimately determine the success of electric vehicles in the market.

Components of Electric Car Batteries

Electric car batteries are the powerhouse of electric vehicles, providing the necessary energy to power the motors that drive the car. These batteries are made up of several key components, including electrodes, electrolytes, and separators. The electrodes are typically made of materials like lithium or nickel-cobalt-aluminum (NCA), which are responsible for storing the energy.

The electrolytes are the liquid or gel-like substance that allows charged particles, or ions, to move between the electrodes. Separators, which are typically made of polyethylene or polypropylene, physically separate the electrodes to prevent short circuits. All these components work together to produce a reliable and efficient source of energy for electric cars, providing a viable alternative to traditional gasoline engines.

As the world continues to shift towards sustainable energy sources, electric car batteries will undoubtedly play a critical role in shaping the future of transportation.

Battery Chemistry

Electric car battery construction is a complex process that involves several steps and uses different materials. One of the main factors that determine the performance of an electric car battery is the chemistry used in its construction. Lithium-ion is the most common battery chemistry used in electric vehicles due to its high energy density and relatively stable performance.

However, different lithium-ion chemistries exist, such as nickel cobalt aluminum (NCA), nickel manganese cobalt (NMC), and lithium iron phosphate (LFP), each with its own advantages and disadvantages. NCA, for instance, has a higher energy density than NMC but is also more expensive. LFP, on the other hand, is cheaper and safer but has a lower energy density.

The choice of battery chemistry depends on factors such as cost, performance, and safety requirements. Battery manufacturers may use a combination of chemistries to achieve the desired performance and optimize the battery’s cost-effectiveness for electric car applications.

Lithium-Ion Battery Chemistry

Lithium-ion battery chemistry is a fascinating topic when it comes to energy storage. The chemistry behind these batteries is complex but essential to understand how they work. As the name suggests, these batteries use lithium ions as the electrolyte to store and release electrical energy.

Lithium-ion batteries consist of an anode, a cathode, and an electrolyte in between. The anode and cathode are generally made of carbon and lithium cobalt oxide, respectively. When the battery is charged, the lithium ions move from the cathode to the anode, where they are stored.

When the battery is in use, these ions move back to the cathode, causing an electrical current to flow through the circuit. The use of lithium ions as the electrolyte makes these batteries highly efficient and compact, which is why they are widely used in portable electronic devices and electric vehicles. However, their use is not without challenges, such as overheating and safety concerns.

Lithium-ion battery chemistry is constantly evolving, and scientists are always looking for new ways to improve the performance and safety of these batteries.

Nickel-Metal Hydride Battery Chemistry

Nickel-metal hydride (NiMH) batteries are one of the most popular types of rechargeable batteries in use today. This battery chemistry is relatively new compared to other battery technologies, but it has become a popular choice for portable electronics and electric vehicles. The chemistry of NiMH batteries is based on the circulation of nickel hydroxide and metal hydride.

These materials are housed in a sealed metal container with an electrolyte solution, which allows for the transfer of electrons between positive and negative poles. One of the primary advantages of NiMH batteries is their high energy density, which means they can store a large amount of electrical energy in a small space. Another advantage of NiMH batteries is their ability to maintain consistent performance over multiple charging and discharging cycles, making them a reliable and cost-effective choice for most applications.

However, there are some drawbacks to this battery chemistry, including their tendency to self-discharge over time and their relatively short lifespan compared to other rechargeable battery technologies. Overall, NiMH batteries are a great choice for most applications, providing an excellent balance of cost, performance, and reliability.

Solid State Battery Chemistry

Solid state battery chemistry refers to the use of solid electrolyte materials in battery systems instead of the more commonly used liquid electrolytes. This solid state technology has the potential to revolutionize the world of batteries. Solid state batteries can be more efficient, longer-lasting, and safer than traditional batteries because they don’t rely on flammable chemicals.

They also have the potential to reduce the size and weight of batteries which could lead to great improvements in electronic devices, electric cars, and energy storage systems. One of the main materials being studied for solid state batteries is lithium-ion, considered a promising candidate due to its high energy density. However, more research is needed to fully understand and optimize the potential of solid state battery chemistry.

Nonetheless, it is clear that this technology holds great promise for the future of energy storage.

Battery Management System

Electric car battery construction is a complex process that involves precision engineering and careful planning to create a reliable and efficient energy storage system. A key component of electric vehicle (EV) batteries is the battery management system (BMS). This system helps regulate the flow of energy in and out of the battery, monitoring vitals such as cell temperatures and voltages, preventing overcharging, and balancing individual cell charge levels.

The BMS not only ensures the safety of the battery system but also maximizes the battery’s lifespan and performance. Advanced BMS can also collect data on driving habits and adjust its control strategy to optimize the battery’s performance according to the driver’s needs, ultimately improving the EV’s overall efficiency. A well-designed BMS is critical in the construction of electric vehicle batteries, ensuring a smooth, safe, and energy-efficient driving experience for EV owners.

Importance of Battery Management System

Battery management systems (BMS) are critical components in ensuring the long-term reliability and safety of batteries, whether used in electric vehicles, renewable energy systems, or consumer electronics. A BMS monitors and controls various parameters of the battery, including temperature, state-of-charge, and charging/discharging rates, to prevent overcharging, over-discharging, overheating, or short-circuiting. It also provides information on the battery’s health, performance, and remaining capacity, allowing users to optimize its usage, reduce downtime, and plan for replacement or recycling.

Think of a BMS as the brains of a battery, constantly analyzing and adjusting its behavior based on real-time data and user preferences. Without a BMS, batteries are prone to premature degradation, failure, or even catastrophic events. Therefore, investing in a high-quality BMS is essential for anyone relying on battery-powered devices or systems, not only for efficiency and cost savings but also for safety and sustainability.

Functions of Battery Management System

A battery management system (BMS) is an essential component in electric vehicles (EVs) and hybrid electric vehicles (HEVs). It is responsible for ensuring that the battery performs optimally and remains safe while in use. The BMS has several functions, including monitoring the battery’s state of charge, state of health, temperature, and voltage.

These factors are important because they affect the battery’s performance and lifespan. The BMS also regulates the battery’s charging and discharging processes to prevent overcharging and excessive depletion, which can damage the battery. Additionally, the BMS provides real-time data about the battery’s condition, which is crucial for diagnosing any issues and providing preventative maintenance.

Overall, the BMS plays a critical role in ensuring the safety, reliability, and longevity of the battery in EVs and HEVs.

Future of Electric Car Batteries

Electric car battery construction has been a topic of interest for years as the demand for electric vehicles continues to rise. The future of electric car batteries is all about increasing the battery range and lifespan while reducing costs. The most common type of electric car battery is lithium-ion, which consists of a cathode, anode, separator and electrolyte.

Researchers are working on improving the cathode material by experimenting with new chemical compositions that offer higher energy density and longer lifespan. The anode material is also being improved by introducing silicon, which can store more energy than traditional graphite. In addition, solid-state batteries are being developed to replace the liquid electrolyte with a solid ceramic or polymer conductor, which offers higher energy density and increased safety.

The evolution of electric car battery construction is crucial to making electric cars more affordable and practical for everyday use.

Conclusion

In conclusion, building an electric car battery is like building a tiny power plant on wheels. The science, engineering, and attention to detail required is no small feat. But with each advancement in battery technology, we are one step closer to a cleaner and more sustainable future.

So, charge up your sense of curiosity and embrace the electrification of transportation – because the energy revolution is here to stay!”

FAQs

What are the materials commonly used in the construction of electric car batteries?

Electric car batteries can be made of several materials, including lithium-ion, nickel-metal hydride, and lead-acid.

How long does it take to produce an electric car battery from scratch?

The time it takes to produce an electric car battery from scratch varies depending on the type of battery and the manufacturing process used. It can range from a few hours to several weeks.

How does the construction of an electric car battery differ from that of a traditional car battery?

Electric car batteries are typically larger and use different materials than traditional car batteries. They also require special cooling systems and may have different charging requirements.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. Many manufacturers offer programs to collect and recycle used batteries, and the materials used in the batteries can be reused in other products.