Revving up the Future: Top Electric Car Battery Manufacturing Companies in India

Electric cars offer numerous benefits over conventional combustion engine vehicles, including lower emissions and lower fuel costs. As the demand for electric cars continues to grow, so does the need for electric car battery manufacturing. India is poised to become a hub for electric car battery manufacturing, thanks to its abundant solar power resources and the government’s push towards electric mobility.

With a population exceeding 3 billion people, India has the potential to become a major player in the global electric car market. In this blog post, we’ll take a closer look at the current state of electric car battery manufacturing in India and what the future holds for this emerging industry.

Overview of Electric Car Batteries in India

India has been expanding its market in renewable energy sources, which includes electric car batteries. There are several electric car battery manufacturing companies in India that specialize in creating high-quality lithium-ion batteries for electric vehicles. These companies include Exide, Amara Raja Batteries, and Tata Chemicals, just to name a few.

They have been at the forefront of research and development in creating lightweight and durable battery solutions that can withstand the vast range of Indian weather conditions. Moreover, these companies focus on providing customers with affordable and reliable batteries for their electric vehicles. With the growing popularity of electric cars in India, these manufacturing companies are investing heavily in research and innovative technology, which should result in further advancements in electric vehicle battery technology in the coming years.

Types of Electric Car Batteries in India

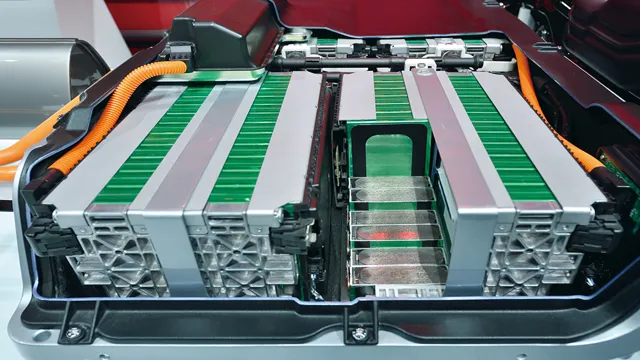

Electric Car Batteries in India When it comes to electric car batteries in India, there are several different types available on the market. One of the most popular options is lithium-ion batteries, which are known for their high energy density and long lifespan. These batteries are used in most electric cars because they offer a good balance between performance, cost, and safety.

Another type of battery that is gaining popularity is solid-state batteries, which have the potential to offer even higher energy densities and faster charging times than lithium-ion batteries. However, these batteries are still in the early stages of development and are not yet widely available. Other types of electric car batteries that are used in India include lead-acid batteries, nickel-metal hydride batteries, and sodium-ion batteries.

Each of these battery types has its own advantages and disadvantages, and the choice of battery will depend on factors such as cost, performance, and safety. Overall, electric car batteries in India are continuously improving, and we can expect to see even more advanced battery technologies in the future.

Major Electric Car Manufacturers in India

Electric Car Batteries in India Electric cars are becoming increasingly popular in India especially due to their environmentally friendly nature. One of the key components of electric cars is the battery that stores and supplies power to the electric motor. In India, various car manufacturers are working with different types of batteries for their electric vehicles.

Lithium-ion batteries are the most commonly used batteries in electric cars in India. However, there are other battery technologies being used such as lead-acid batteries and nickel-metal hydride batteries. The cost of electric cars largely depends on the type of battery used as they form a significant portion of the total cost of the car.

Battery technology is evolving rapidly with researchers working towards developing cheaper, more durable and efficient batteries. Additionally, charging infrastructure for electric cars is still in its nascent stage in India and is another aspect that needs to be improved. Despite these challenges, the demand for electric cars in India is increasing and the government is taking steps towards promoting the adoption of electric vehicles with various incentives and subsidies.

Top Electric Car Battery Manufacturers in India

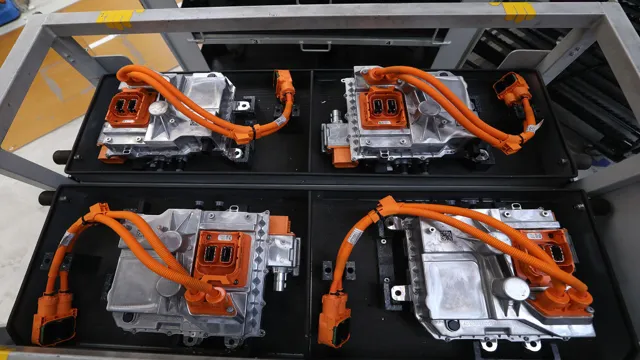

If you’re looking for electric car battery manufacturing companies in India, there are a number of reputable options to choose from. One of the top manufacturers is Amara Raja Batteries, which has a strong focus on renewable energy and produces batteries for both two- and four-wheeled electric vehicles. Exide Industries is another well-known name in the battery industry, with a range of products designed for both electric vehicles and stationary energy storage.

Meanwhile, Tata Chemicals has recently gotten into the EV battery game, with their new advanced lithium-ion battery cell manufacturing facility in Gujarat. Other players in the Indian market include HBL Power Systems, Bharat Heavy Electricals Limited (BHEL), and many more. With a growing demand for electric vehicles, it’s likely that we’ll see continued innovation and expansion within the Indian electric car battery manufacturing industry in the years to come.

Bharat Heavy Electricals Limited (BHEL)

Bharat Heavy Electricals Limited (BHEL) When it comes to the top electric car battery manufacturers in India, Bharat Heavy Electricals Limited (BHEL) is one of the most reputable names in the industry. The company has been a significant contributor to the Indian economy for decades, and their range of electric car batteries is impressive. BHEL has a strong commitment to innovation, and they are continually working to improve their products’ efficiency while keeping them affordable for customers.

They understand that electric cars are the future of the automotive industry, and they are fully dedicated to supplying high-quality batteries to ensure the success of this market. BHEL is a trusted provider of electric car batteries to Indian car manufacturers, and their products are known for their durability, reliability, and long lifespan. If you’re looking for a reliable and cost-effective solution for your electric car needs, BHEL’s range of batteries is an excellent choice.

Exide Industries Limited

Exide Industries Limited is one of the top electric car battery manufacturers in India. With over six decades of experience in producing high-quality batteries, Exide has been a trusted name in the market. The company offers a wide range of batteries for electric vehicles, including lithium-ion batteries that are known for their high energy density and long lifespan.

These batteries are designed to provide reliable performance, longer driving ranges, and quick charging times. Exide Industries Limited has been at the forefront of electric vehicle battery technology in India and has been investing heavily in research and development to improve its products further. The company’s goal is to provide sustainable and green transportation solutions to the market, and its electric vehicle batteries are a step in that direction.

With Exide’s commitment to innovation and sustainability, it is no wonder that it is one of the top players in the Indian electric vehicle battery market.

Amara Raja Batteries Limited

When it comes to finding the top electric car battery manufacturers in India, one name that stands out is Amara Raja Batteries Limited. The company has a strong reputation for providing high-quality batteries for a range of applications, including electric cars. With a focus on innovation and sustainability, Amara Raja Batteries Limited has developed cutting-edge technologies to produce batteries that are both efficient and environmentally friendly.

Their batteries are designed to provide long-lasting performance, with a range of features that make them ideal for use in electric vehicles. So if you’re looking for a reliable and efficient electric car battery manufacturer in India, look no further than Amara Raja Batteries Limited.

Challenges and Opportunities in Indian Electric Car Battery Manufacturing

Electric car battery manufacturing companies in India are facing both challenges and opportunities. On one hand, they have the chance to tap into the growing demand for electric vehicles both within India and globally. On the other hand, they have to contend with issues around infrastructure and availability of raw materials.

India is still in the process of setting up an adequate charging infrastructure for electric vehicles, which hampers adoption rates. Additionally, battery manufacturing companies have to rely on imports for certain key metals and minerals used in batteries. However, the Indian government’s push towards self-sufficiency and local manufacturing has created opportunities for battery manufacturers.

The National Programme on Advanced Chemistry Cell Battery Storage aims to support the growth of domestic manufacturing and reduce reliance on imports. Additionally, the development of a robust supply chain for raw materials within the country can also support the growth of battery manufacturing in India. Overall, while there are challenges, the Indian electric car battery manufacturing industry has a promising future.

Government Initiatives to Boost Electric Car Manufacturing

India’s push towards electric vehicles has led to a surge in demand for electric car battery manufacturing. The Indian government has announced several initiatives to promote the production of electric vehicles in the country, including the Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme, which offers incentives to both manufacturers and buyers of electric vehicles. However, while there are opportunities for growth in the electric car battery manufacturing sector, there are also challenges that need to be addressed.

One of the main challenges is the lack of raw materials, such as lithium and cobalt, which are essential for making electric car batteries. Additionally, there is a need for skilled labor and investment in research and development. If India can overcome these challenges, it has the potential to become a leader in electric car battery manufacturing and play a significant role in the global transition towards sustainable transportation.

Environmental Impact of Electric Cars and Battery Manufacturing

Electric Car Battery Manufacturing in India The shift towards electric vehicles has significantly reduced the environmental impact of cars, but it has also raised questions about the manufacturing process of batteries. Battery manufacturing is energy-intensive, and the production of raw materials like cobalt and nickel presents environmental challenges. However, there are also opportunities to address these challenges in India.

The country has abundant reserves of minerals like lithium and cobalt, which are essential for battery production, and the government is making efforts to promote domestic battery manufacturing. To reduce the environmental impact of battery manufacturing, companies can adopt sustainable practices like using renewable energy, reducing waste, and recycling unused materials. Moreover, the Indian government can implement policies that incentivize sustainable manufacturing and encourage research and development in the field.

With these measures, India has the potential to become a major player in electric car battery manufacturing while minimizing its environmental impact.

The Future of Electric Car Battery Manufacturing in India

Electric car battery manufacturing companies in India are seeing a bright future ahead. With the Indian government’s push for electric vehicles, these companies have an opportunity to tap into a burgeoning market. The demand for electric vehicles is only going to increase, and companies involved in the manufacturing of batteries will have a crucial role to play.

India’s energy needs and environmental concerns make electric vehicles an attractive option, and it is expected that by 2030, 30% of all vehicles sold in India will be electric. This presents an excellent opportunity for the electric car battery manufacturing industry to grow. With many major international companies setting up shop in India, it is likely that the country will soon become a hub for electric car battery manufacturing.

Conclusion

In India, the electric vehicle revolution is just beginning to gain momentum, and with it comes a growing number of electric car battery manufacturing companies. With their innovative technologies and commitment to sustainability, these companies represent not only a promising future for the Indian automotive industry, but also a shining example of how business and environmentalism can go hand in hand. So, let’s plug into the future with these electrifying companies and show the world what India is capable of!”

FAQs

What are some of the key players in the electric car battery manufacturing industry in India?

Some of the major companies in the electric car battery manufacturing industry in India include Exide Industries Limited, Amara Raja Batteries Limited, and Tata Chemicals Limited.

Are there any government initiatives to promote the manufacturing of electric car batteries in India?

Yes, the Government of India has launched the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme which aims to promote the manufacture and adoption of electric vehicles including their associated components such as batteries.

Are there any environmental benefits of using electric cars over petrol/diesel cars in India?

Yes, electric cars produce zero tailpipe emissions which means they do not contribute to air pollution in cities. In addition, the use of electric cars can reduce greenhouse gas emissions from the transportation sector which is a major contributor to climate change.

What are some of the challenges faced by electric car battery manufacturing companies in India?

Some of the key challenges faced by electric car battery manufacturing companies in India include high initial capital costs, lack of technological expertise, and shortage of skilled labor. In addition, the lack of a well-developed supply chain and inadequate charging infrastructure can also pose challenges for the growth of the industry.