Revving Up the Future: Exploring the Essential Metals that Power Electric Car Batteries

Are you curious about the metals that make up electric car batteries? If so, you’ve come to the right place! In this article, we’ll reveal everything you need to know about the metals that power electric vehicles. First and foremost, let’s talk about the most common metals used in electric car batteries: lithium, cobalt, and nickel. These metals are essential in creating the chemical reactions that produce electrical energy, allowing for the vehicle to run without gasoline.

Lithium is the primary metal used in electric car batteries, responsible for storing energy and delivering power to the electric motor. Cobalt and nickel are often utilized as cathode materials, allowing for a longer lifespan and better overall performance of the battery. While these metals are critical to the function of electric car batteries, their acquisition can be complicated.

The mining of these materials often leads to environmental degradation and human rights issues. Governments and organizations around the world are working to create more sustainable and ethical ways of obtaining these metals. In conclusion, understanding the metals in electric car batteries is crucial to comprehending the technology that powers these eco-friendly vehicles.

As awareness of environmental issues and sustainability grows, it’s essential to consider the ethical, ecological, and social impact of our choices.

What Metals are Used in Electric Car Batteries?

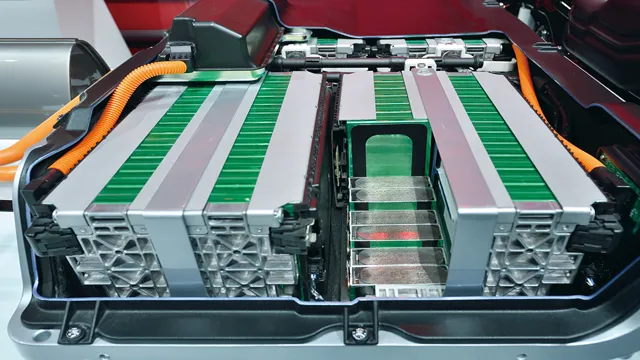

When it comes to the construction of electric car batteries, several metals come into play. Lithium, cobalt, nickel, and manganese are the most commonly used metals in electric car batteries. Lithium, in particular, is the primary component in the battery cathode.

This metal is highly reactive, which ensures that it produces a high electrical potential. Cobalt is also used in the cathode and is responsible for improving battery life and providing stable performance. Nickel provides additional performance benefits, such as extending the battery’s driving range.

Lastly, manganese is used in the cathode to increase the battery’s stability and enhance its thermal durability. In conclusion, the use of these metals in electric car batteries is critical in ensuring the optimal performance of electric vehicles on the road today.

Lithium – The Key Component

Lithium Electric cars have become increasingly popular in recent years, and one of the key components that make them possible is lithium. Lithium, a soft, silvery-white metal, is a crucial ingredient in the batteries that power these vehicles. Other important metals used in electric car batteries include cobalt, nickel, and manganese.

However, lithium is particularly significant because it allows for high energy density and long-lasting battery life. Because of its unique properties, lithium has become a highly sought-after resource in the electric car industry. Despite concerns about the environmental impact of mining for lithium, the demand for electric cars is only set to grow in the coming years, meaning that lithium will likely remain a critical component in this industry for the foreseeable future.

Cobalt – Increasing Scrutiny

Electric car batteries use various metals, including cobalt, lithium, nickel, and manganese. In recent years, cobalt has faced increasing scrutiny due to ethical concerns surrounding its mining practices. Cobalt is predominantly mined in the Democratic Republic of Congo, where human rights violations and child labor have been reported in some mines.

As a result, some automakers and battery manufacturers are working to reduce or eliminate the use of cobalt in their products. Alternatives like lithium iron phosphate (LFP) batteries, which use no cobalt, are gaining popularity due to their safety and sustainability. However, some experts note that cobalt is still critical for high-performance batteries, and efforts should focus on responsible mining practices rather than complete elimination.

Nickel – A Versatile Option

Electric car batteries are a vital component for powering electric vehicles, and several metals are used in the manufacturing process. One of the most versatile options is nickel. It’s a durable metal that can withstand high temperatures and provides good conductivity.

Nickel also has excellent electrochemical properties, making it an effective component for battery electrodes. When nickel is combined with other metals like cobalt and manganese, it creates a stable chemistry that can increase the battery’s energy density, making it more efficient. Furthermore, nickel is abundantly available, and its low cost makes it an attractive option for manufacturers.

Despite its numerous benefits, nickel can be costly when compared to other metals used in EV batteries, such as lithium and graphite. Nonetheless, it remains a popular choice for many battery manufacturers due to its excellent properties.

Manganese – Lower Cost, but Lower Performance

Manganese Electric car batteries have revolutionized the automobile industry and have been crucial in promoting environmentally friendly, sustainable modes of transportation. The metals that constitute electric car batteries include cobalt, nickel, lithium, and manganese. While each metal serves a different purpose in the battery, manganese is a cost-effective option with lower performance compared to its counterparts.

Manganese is often used in combination with other metals to improve battery stability and safety. Although it has a lower energy density, it provides better thermal and chemical stability, which enhances battery life. With the growing demand for electric cars, manganese is becoming increasingly important due to its low cost and high availability.

Nevertheless, researchers are continually working to improve the efficiency of electric car batteries by exploring new materials and methods that can potentially replace or supplement existing ones.

Environmental Impact of Electric Car Battery Metals

Electric car battery metals have the potential to significantly impact the environment, both positively and negatively. As demand for electric vehicles continues to rise, so does the demand for metals such as lithium, cobalt, and nickel, which are used in electric car batteries. While electric cars produce zero emissions during driving, the extraction and production of these metals can have a high carbon footprint, as well as negative impacts on local ecosystems and communities.

Additionally, the disposal of used batteries can also lead to environmental challenges, as they contain toxic metals that can cause pollution if not disposed of properly. It is important that the entire life cycle of electric car batteries is considered when evaluating their environmental impact, from extraction to disposal. Efforts are being made to improve the sustainability of battery production and recycling processes, such as using renewable energy sources and implementing more efficient recycling methods, but there is still much work to be done to ensure a truly sustainable electric vehicle industry.

Mining Practices and Environmental Damage

The environmental impact of electric car battery metals has become a topic of concern in recent years. While the use of electric cars reduces greenhouse gas emissions, the mining practices required to obtain the materials needed for their batteries can cause significant damage to the environment. For instance, the extraction and processing of metals like lithium, cobalt, and nickel can lead to soil and water pollution, deforestation, and displacement of local communities.

Furthermore, the process of manufacturing electric car batteries requires a large amount of energy, which can also contribute to carbon emissions. However, there are efforts being made to reduce the environmental impact of battery metal mining, such as promoting sustainable mining practices and recycling used batteries. By prioritizing sustainable practices and recycling materials, we can reduce the environmental damage caused by the production of electric car batteries and continue to work towards a greener future.

Disposal and Recycling of Batteries

The disposal and recycling of batteries, particularly those used in electric cars, is a crucial issue that has gained more attention in recent years due to the environmental impact of battery metals. These metals, such as lithium and cobalt, are extracted from the earth through mining processes that contribute to significant environmental damage, such as deforestation, soil erosion, and water pollution. In addition to the initial environmental impact of battery production, the disposal of old batteries also poses a threat to the environment if not disposed of properly.

At the end of their lifespan, electric car batteries contain toxic chemicals that can leak into the environment if not recycled or disposed of correctly. Therefore, it is essential to implement effective waste management strategies for battery disposal and recycling to minimize the environmental impact of electric car batteries.

Future of Electric Car Battery Metals

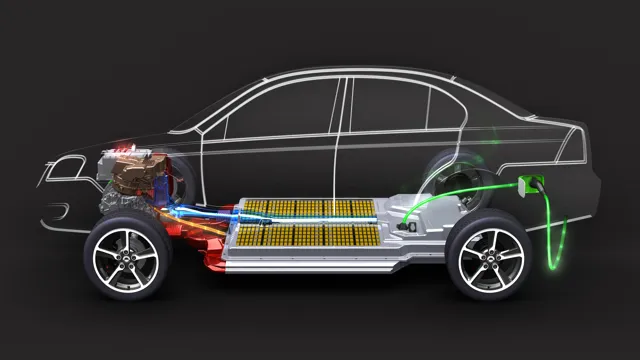

Electric car battery metals are set to play a significant role in the future of the automotive industry. With the growing popularity and emphasis on electric vehicles, the demand for battery metals such as cobalt, nickel, and lithium is set to increase. These metals are integral components of the lithium-ion batteries used in electric cars, and their availability and affordability will be crucial in determining the growth and sustainability of the electric vehicle market.

There is already a significant focus on securing a stable supply of these battery metals, which are mainly found in a few countries. Efforts are being made to invest in mining and production infrastructure to ensure a consistent supply chain. Moreover, research is ongoing to develop alternative battery technologies that use more abundant or less costly metals.

As the electric vehicle market evolves, so will the demand and supply dynamics of the battery metals market, making it an exciting area to watch.

Innovations in Battery Technology

As electric cars continue to gain popularity, the demand for materials used in battery production is increasing rapidly. However, some of these metals such as cobalt, nickel, and lithium are not abundant and can be challenging to extract. This has led to the exploration of alternative metals such as manganese, aluminum, and zinc, which are more abundant and can potentially replace the traditional battery metals.

Despite this, the traditional metals still remain important as they offer superior performance and longevity. This creates a dilemma for manufacturers and researchers who are looking to find a balance between sustainability and functionality. It is clear that the future of electric car battery metals will heavily rely on innovation and discovery of new materials that offer a balance between superior performance and sustainability.

Emerging Alternatives to Common Metals

The future of electric car battery metals is looking bright, as new alternatives to common metals are emerging. One such alternative is graphene, a thin layer of carbon that has shown promise as a material for battery electrodes. Graphene is incredibly strong, lightweight, and conductive, making it an ideal choice for electric car batteries.

Another promising alternative is sodium, which unlike lithium, is abundant and inexpensive. Sodium-ion batteries have the potential to be cheaper than lithium-ion batteries, making them a viable option for electric cars. Additionally, researchers are exploring the use of magnesium and aluminum as potential battery materials.

While these alternatives are still in the early stages of research and development, they show great potential for the future of electric car battery metals. As the demand for electric cars continues to grow, it’s exciting to see new and innovative materials being considered for use in their batteries.

Conclusion

In conclusion, the world of electric car battery metals may seem daunting and complex, but it’s really quite simple. Just like a recipe, each metal plays a unique role in creating the perfect battery. From the sweet flavour of lithium to the bold kick of cobalt, these elements combine to power the vehicles of the future.

So if you’re looking to drive towards a more sustainable future, just remember: it all starts with the right mix of metals. Bon appétit!”

FAQs

What are the primary metals used in electric car batteries?

The primary metals used in electric car batteries are lithium, cobalt, nickel, and manganese.

How does the use of these metals impact the overall cost of electric car batteries?

The use of these metals can impact the overall cost of electric car batteries due to their limited availability and high demand in the market.

Are there any environmentally friendly alternatives to these metals for electric car batteries?

Researchers are exploring alternatives such as aluminum and magnesium for electric car batteries as more environmentally friendly options.

What is the lifespan of electric car batteries made with these metals?

The lifespan of electric car batteries made with these metals can vary depending on usage, but they typically last between 8-10 years before needing replacement.