Powering the Future: How Electric Car Battery Production is Reducing CO2 Emissions

Have you ever stopped to think about the environmental impact of the electric cars we’re all so excited about? Admittedly, electric cars are much better for the planet than their gas-guzzling counterparts in terms of emissions; however, there’s a hidden impact of the booming electric car industry that we don’t often talk about: the production of electric car batteries. The production of these batteries generates a significant amount of CO2 emissions, which has an impact on the environment. In this blog post, we’ll dive into the topic of electric car battery production and CO2 emissions, exploring what the situation looks like today and what can be done to mitigate the impact.

So buckle up and get ready to learn more about this crucial topic, with a focus on how we can ensure environmentally friendly and sustainable electric car battery production.

Overview

Electric car battery production is known for generating a considerable amount of CO2 emissions during its manufacturing process. While electric cars have been generally regarded as a cleaner and more efficient alternative to gasoline vehicles, the production of lithium-ion batteries remains a major concern. The CO2 emissions generated during their manufacturing can offset the benefits of electric cars on the environment.

However, there is hope in minimizing these emissions as the industry looks towards sustainable sourcing of raw materials and renewable energy sources during production. With the advancements in technology and the proactive efforts of companies, such as Tesla, towards green manufacturing, it is becoming increasingly possible to produce EV batteries with less environmental impact. By reducing the carbon footprint of electric car battery production, we can ensure that the future of EVs will be truly sustainable.

The Environmental Impact

The environmental impact of any product or activity should always be a significant concern. In the case of the fashion industry, the impact is far-reaching, from the production and transportation of raw materials to the disposal of garments at the end of their lifecycle. The industry has been labeled as one of the world’s most polluting, with a high carbon footprint, water pollution, and depletion, and an enormous amount of waste generated.

The use of pesticides and fertilizers in cotton production heavily impacts soil and water resources, leading to decreased crop quality and harm to local ecosystems. Additionally, the transportation methods employed by fashion companies put significant pressure on the environment. The high number of garments produced also means that a vast quantity of clothing is disposed of in landfills each year.

By making conscious fashion choices, such as buying from sustainable fashion businesses, buying second-hand clothing, and recycling or upcycling, individuals can help reduce the negative environmental impact of the fashion industry.

Evolution of Battery Technology

When it comes to technology, batteries have come a long way since their invention in the 18th century. From the first primitive voltaic pile to modern lithium-ion batteries, the evolution of battery technology has been nothing short of impressive. Today, batteries are found in everything from smartphones and laptops to electric vehicles and even the power grid.

As technology advances, so too does the demand for better and more efficient battery technology. Companies are constantly working to develop more advanced batteries that are lighter, longer-lasting, and more sustainable. In fact, the keyword for this evolution has been sustainability.

With the rise of renewable energy, the importance of high-performance batteries that can store excess energy from sources such as solar and wind power has become essential. The world is now at the forefront of ushering a new era of energy transition, the rising popularity of electric vehicles, and sustainable power grids.

CO2 Emissions in Battery Manufacturing

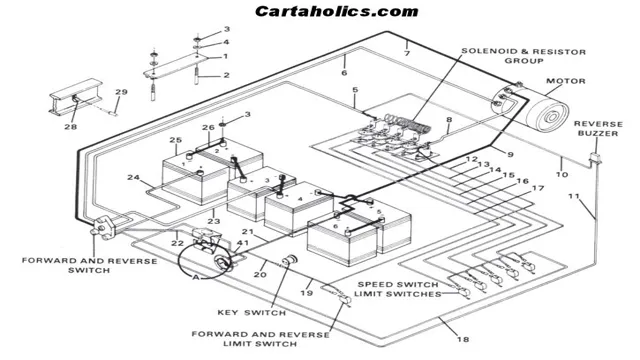

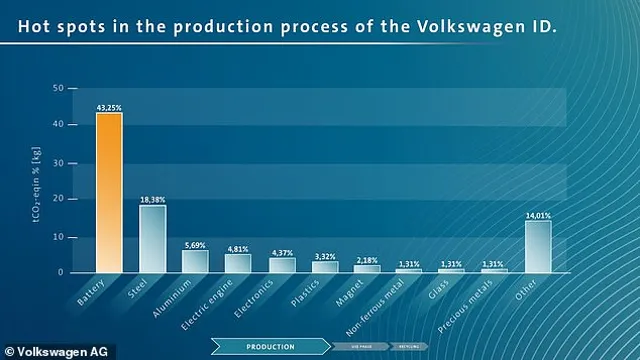

Electric car battery production generates a significant amount of CO2 emissions. The production of batteries requires energy-intensive processes that emit carbon dioxide throughout every stage of production, from manufacturing to transportation. The majority of the carbon emissions result from the mining and refining of metals such as lithium, cobalt, and nickel, which are used to create the critical components of an electric car battery.

The mining process often involves the use of fossil fuels, resulting in significant greenhouse gas emissions. Additionally, the transportation of raw materials and finished batteries from one location to another also accounts for a significant share of the carbon footprint. Moreover, the energy required to produce batteries, including the energy consumed in the manufacturing process, uses a lot of fossil fuels, including coal and natural gas, all of which generate CO2 emissions.

However, significant progress is being made to reduce the carbon emissions associated with battery production, such as developing more efficient recycling systems and improving sourcing practices, which are essential to reduce the environmental effects of electric car battery production.

Sources of Emissions

CO2 emissions, Battery manufacturing One of the main sources of CO2 emissions is battery manufacturing. While battery-powered vehicles and renewable energy sources are great for reducing greenhouse gas emissions, the production of batteries that power these technologies can be quite significant when it comes to CO2 emissions. Many of the materials that are used in battery production, such as lithium, cobalt, and nickel, are mined and processed in a way that contributes to substantial emissions.

Additionally, the process of assembling batteries requires a considerable amount of energy, which often relies on fossil fuels. However, there are efforts to minimize these emissions, such as the use of renewable energy sources for battery manufacturing and the development of more sustainable processes. By continuing to investigate and implement sustainable solutions, we can reduce the impact of battery production on our planet’s climate.

Measuring Emissions

When we think about EVs, we often assume they are cleaner because they do not emit any emissions while driving. However, the production of EV batteries emits a significant amount of carbon dioxide. According to a report by the European Federation for Transport and Environment, manufacturing a battery for a mid-sized EV emits around

8 tons of CO This is mostly due to the production of the anode and cathode materials, which require significant amounts of energy to produce. However, it is important to note that despite the emissions from battery production, EVs still have a lower carbon footprint compared to traditional gasoline-powered cars throughout their lifetime.

Solutions such as using recycled or renewable materials in the battery production process can further lower the emissions associated with EV manufacturing. Overall, while it is important to acknowledge the emissions associated with battery production, the benefits of transitioning to EVs far outweigh the environmental costs.

Comparison with Fossil-Fuel Cars

When people talk about the environmental impact of electric cars, one common argument against them is that the production of their batteries generates significant carbon emissions. While it is true that manufacturing batteries does produce large amounts of CO2, it is important to understand how that compares to the emissions created by producing internal combustion engines for traditional vehicles. In fact, studies have shown that the carbon footprint of an electric car battery is still significantly lower than that of a gasoline-powered car over the lifetime of the vehicle.

This is due to the significant reduction in emissions during the vehicle’s operation, as electric cars don’t emit any harmful gases while driving. Furthermore, as battery technology advances and production becomes more efficient, the carbon footprint of battery manufacturing will continue to decrease. So while it is important to consider the environmental impact of manufacturing electric car batteries, it should not be seen as a reason to dismiss the benefits of electric transportation as a whole.

Solutions to Reduce CO2 Emissions in Battery Production

Electric car battery production generates a substantial amount of CO2 emissions. However, there are several solutions that can help reduce the environmental impact of this process. One way is to increase the use of renewable energy sources such as solar or wind power in the manufacturing process.

Another option is to prioritize the reuse and recycling of materials used in battery production. This can be achieved through the development of more sustainable and circular supply chains. Additionally, using more environmentally friendly manufacturing processes, such as water-based coatings and non-toxic solvents, can also significantly reduce CO2 emissions in battery production.

By implementing these solutions, we can make electric car battery production more sustainable and reduce our collective carbon footprint.

Renewable Energy for Manufacturing

Renewable Energy for Manufacturing Battery production is one of the most energy-intensive processes in the manufacturing industry, emitting a significant amount of CO Fortunately, there are solutions to reduce these emissions, such as implementing renewable energy sources. By using renewable energy sources like solar or wind power, battery manufacturers can significantly reduce their carbon footprint.

Additionally, energy-efficient equipment such as high-efficiency pumps, motors, and compressors, can also reduce emissions by lowering the amount of electricity consumed during production. Companies can also invest in energy storage solutions or demand response programs to reduce peak energy demand during production. Overall, incorporating renewable energy sources and energy-efficient equipment into battery production processes can lead to reduced CO2 emissions and a more sustainable future.

Recycling and Reusing Batteries

Battery production plays a significant role in carbon dioxide emissions, which makes recycling and reusing batteries a more sustainable solution. Manufacturers can reduce their carbon footprint by using recycled materials in the production process. Recycling batteries involves extracting useful materials to recover precious metals like copper and aluminum, reducing the environmental impact of mining activities.

However, battery recycling poses a challenge as it requires complex and costly processes. Reusing batteries can also be an effective solution, particularly in the automotive and energy sectors, where batteries can be repurposed as backup power sources or storage for renewable energy. Additionally, battery technology is continually advancing, and sustainable production methods, including using renewable energy sources, can significantly reduce CO2 emissions.

By implementing a circular economy approach, we can transition to a more sustainable battery industry and reduce our carbon footprint.

Conclusion

We all want to believe that electric cars are the solution to our environmental woes, but the truth is that producing the batteries for these cars still comes with a hefty carbon footprint. However, don’t be deterred! As the technology for producing these batteries continues to improve and more renewable energy sources are utilized in the production process, the future for electric cars looks brighter than ever. So, let’s embrace the electric revolution and work together towards a greener tomorrow!”

FAQs

What is the impact of electric car battery production on CO2 emissions?

Electric car battery production has a significant impact on CO2 emissions. The production process requires large amounts of energy, and the majority of the energy comes from non-renewable sources, which increases greenhouse gas emissions.

Can electric car manufacturers reduce CO2 emissions during battery production?

Yes, electric car manufacturers can reduce CO2 emissions during battery production by using renewable energy sources such as solar, wind and hydro power. Additionally, producing batteries with recycled materials can also reduce CO2 emissions.

What is the current global production of electric car batteries?

The current global production of electric car batteries is estimated to be around 320 GWh (gigawatt-hours). This is expected to increase significantly in the coming years as the demand for electric vehicles rises.

How can consumers reduce their carbon footprint when charging their electric cars?

Consumers can reduce their carbon footprint when charging their electric cars by using renewable energy sources for charging such as solar panels and wind turbines. Additionally, charging during off-peak hours or when the grid is fueled by renewable energy sources can also help reduce carbon emissions.