Revolutionizing Automotive Industry with Sustainable Electric Car Battery Raw Materials

As the world strives towards a more sustainable future, electric vehicles are fast becoming the norm. However, while we may understand the benefits of driving an electric car, the science behind it remains somewhat of a mystery. One area that seems to cause the most confusion is the battery.

What are electric car batteries made from? What materials are needed to build them? In this blog post, we will explore the raw materials that make up electric car batteries, and what implications they carry for the planet.

Introduction

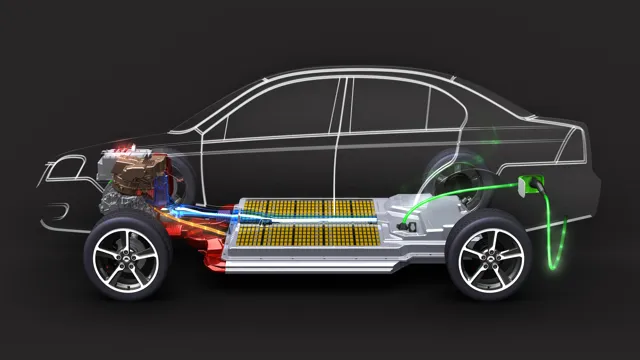

When we talk about electric cars, the electric car battery raw materials play a vital role in their overall efficiency. The main components used in electric car batteries are lithium, cobalt, nickel, and manganese, which are essential for storing and delivering electrical energy. Besides, the use of these raw materials in electric car batteries has significantly contributed to improving the performance of electric vehicles, such as range and power.

However, the increased demand for electric vehicles has put pressure on the availability and affordability of these raw materials. As a result, research is ongoing to identify alternative materials that have the same properties as the current ones but are cheaper and more readily available. Although it is a challenging area to explore, the future is promising, and it is expected that with time, new materials will be discovered, leading to more sustainable and cost-effective methods of energy storage that will revolutionize the automotive industry.

Why Raw Materials are Important for Electric Car Batteries

Raw Materials for Electric Car Batteries Introduction: Electric cars have become increasingly popular, and it is expected that their demand will continue to rise. However, what many people do not realize is that electric car batteries depend on critical raw materials. These materials are essential for the manufacturing of electric car batteries and play a crucial role in determining the car’s range, lifetime, power, and overall performance.

In this blog section, we will discuss why raw materials are important for electric car batteries and the significance of their availability, sustainability, and ethical production.

Key Raw Materials for Electric Car Batteries

Electric car batteries are one of the essential components that make electric vehicles possible. These batteries power the motor and provide the range for the car to operate for extended periods. However, making electric car batteries requires some specific raw materials to achieve the desired performance.

Key raw materials for electric car batteries include lithium, cobalt, nickel, and manganese. Lithium is the most critical element used in electric car batteries, and it accounts for around 90% of the battery size by weight. Cobalt is another essential ingredient used in some lithium-ion batteries to maintain stability and prevent overheating.

Meanwhile, nickel and manganese account for a smaller portion of the battery construction but are still necessary to maintain the battery’s durability. These raw materials are continually evolving, and new compositions are being developed to improve battery capacity, longevity, and environmental sustainability.

1. Lithium

When it comes to electric car battery raw materials, one of the primary components is lithium. As a highly reactive element, lithium is capable of storing a significant amount of energy and retaining it over long periods of time. This makes it an ideal choice for electric car batteries, which require a high level of energy density to power the vehicle effectively.

In addition to its energy storage capabilities, lithium is also relatively lightweight and abundant, making it a cost-effective option for manufacturers. While alternatives to lithium are being explored, it remains a critical component in the production of electric car batteries. With the rise in popularity of electric vehicles, demand for lithium is only expected to increase in the years to come.

Why Lithium is a Popular Choice

Lithium is a highly popular choice when it comes to powering electronic devices, thanks to its exceptional characteristics. It is a soft, lightweight, and silvery-white metal that is highly reactive and flammable, which gives it a unique advantage over other metals. Lithium is one of the most abundant elements in the earth’s crust and is found in rocks, soil, and groundwater.

Lithium-ion batteries have become the most popular energy storage system in recent years due to their high energy density, fast charging capabilities, and long lifespan. They are commonly used in smartphones, laptops, electric vehicles, and other portable devices due to their ability to provide high power output while being lightweight and compact in size. Moreover, they are environmentally friendly as they do not produce harmful emissions, making them a sustainable and safe option for the environment.

Thus, lithium’s numerous advantages make it a popular choice for powering modern-day devices, providing efficient and reliable energy storage solutions.

Environmental Impact of Lithium Mining

Lithium, one of the most widely used materials in modern batteries, is extracted through a process known as lithium mining. Although lithium is considered a critical component in the transition to a low-carbon future, the environmental impact of lithium mining cannot be ignored. The extraction process involves huge amounts of water, energy, and various chemicals, leading to severe pollution of surrounding air, water, and soil.

Moreover, as demand for lithium grows, so does the need for more mining, leading to further ecological destruction. The environmental impacts of lithium mining are not just limited to local ecosystems, but they also affect global climate change. As consumers, it’s crucial that we understand these environmental impacts and make informed choices while purchasing products that use lithium batteries.

While the growing demand for renewable energy is a positive step towards a sustainable future, it must not come at the cost of the environment.

Future Outlook for Lithium Raw Materials

Lithium is an essential raw material used to manufacture rechargeable batteries found in electronic devices like smartphones and laptops. The market for lithium is booming, and its demand is only going to increase in the coming years as the world shifts toward green energy solutions. Major car manufacturers like Tesla and Volkswagen are investing heavily in the production of electric vehicles, and this is expected to massively increase the demand for lithium.

As a result, lithium prices have soared, and the mining industry is racing to supply the market with enough lithium. Despite the high demand for lithium, concerns have been raised about the sustainability of its extraction and production. Lithium mining has been linked to environmental damage and water depletion in regions where it takes place.

This has led to calls for the industry to prioritize sustainability as it continues to meet the growing demand. The future outlook for lithium raw materials will depend largely on how the supply chain can achieve sustainability and mitigate the negative environmental impacts associated with lithium mining. However, with continued innovation and investments in clean energy, the future looks bright for this precious metal.

2. Cobalt

Electric car battery raw materials play a crucial role in the sustainability of electric vehicles. Cobalt is one of these essential raw materials, and it’s used in lithium-ion batteries, which are responsible for powering most of the electric cars on the market today. This bluish-gray metal can be found in countries such as the Democratic Republic of Congo, which provides approximately 60% of global cobalt production.

Cobalt has unique properties that make it ideal for battery production, including its ability to withstand high temperatures and remain stable under high charge and discharge cycles. However, the mining of cobalt has raised concerns over the exploitation of child labor and environmental damage. Therefore, it is essential to search for alternatives and sustainable supply chains that ensure the ethical production of cobalt.

The electric car industry needs to keep striving to find more ethical and sustainable ways of using cobalt and other raw materials to reduce their impact on the environment and create a safer future.

Why Cobalt is Important for Electric Car Batteries

Cobalt is a vital element in the construction of electric car batteries, and for a good reason. In fact, cobalt is an essential component in all lithium-ion batteries since it provides high energy density while also maintaining stability during charging and discharging cycles. The demand for cobalt in the electric automotive industry has skyrocketed, with cobalt currently constituting approximately 35% of the total cost of an electric vehicle battery.

However, the extraction of cobalt comes at a significant cost, both to the environment and the human cost of mining in nations like the Democratic Republic of the Congo. Companies in the electric car industry are making significant efforts to reduce their reliance on cobalt and find alternative materials that don’t have such consequences. The electric car industry is evolving, and as battery technology becomes more advanced, it may be possible to reduce or even eliminate the use of cobalt altogether, leading to a greener and more sustainable future for all.

Challenges with Cobalt Supplies

Cobalt is an essential element for the production of electric car batteries, but it’s sourced almost exclusively from the Democratic Republic of Congo (DRC), where it’s often mined through unethical and exploitative practices. The DRC is also politically unstable, creating challenges for cobalt supplies and driving up the price. Additionally, as electric cars become more popular, demand for cobalt is expected to rise dramatically, potentially causing shortages and further price increases.

This creates a dilemma for the electric car industry, which is trying to create sustainable, ethical, and affordable vehicles. Manufacturers are exploring ways to reduce the amount of cobalt needed in batteries, or to source cobalt from other regions where mining practices are more responsible. However, these solutions are not yet scalable or readily available, posing a significant challenge for the industry in the years to come.

Alternatives to Cobalt

Cobalt is a crucial element in the manufacturing of lithium-ion batteries. However, the supply chain for cobalt has been linked to unethical practices, like child labor and dangerous working conditions. This has led to a push for alternatives to cobalt in the battery industry.

One promising alternative is nickel-cobalt-manganese (NCM) batteries, which use less cobalt and more nickel and manganese. Another option is lithium-iron-phosphate (LFP) batteries, which don’t use cobalt at all and are already being used in some electric vehicles. While these alternatives may have their own drawbacks, such as lower energy density and shorter lifespan, the push for more sustainable and ethical battery production is driving increased research and development in this area.

3. Nickel

Nickel is a crucial element used in electric car battery raw materials. It provides essential properties such as durability, reliability, and high energy ability. Electric car batteries require a large amount of nickel to ensure maximum efficiency and improved performance.

Nickel makes up approximately one-third of the battery content in Tesla electric vehicles. The increasing demand for electric cars and sustainable energy is driving the growth of nickel mining and refining worldwide. While nickel is abundant, it remains in high demand due to the rapid expansion of the electric vehicle market.

The use of nickel helps in reducing the environmental impact of cars as they contribute to the reduction of greenhouse gases. Electric vehicles with nickel batteries emit less pollution and require less maintenance, which makes driving more cost-effective and environmentally friendly. Thus, nickel is an essential element to the future of sustainable transportation and contributes significantly to the global effort to decrease carbon emissions.

Advantages of Nickel in Electric Car Batteries

Nickel is a highly advantageous metal when it comes to electric car batteries. One of the biggest benefits of using nickel in electric car batteries is that it greatly improves the energy density of the battery. This means that the battery can store more energy in a smaller space, which ultimately allows the car to drive farther on a single charge.

Additionally, nickel is a very durable and long-lasting metal, meaning that batteries containing nickel are able to withstand more charge and discharge cycles. This also means that the batteries require less maintenance over time, which can ultimately save drivers money in the long run. Overall, the use of nickel in electric car batteries is a significant asset that allows electric cars to be more efficient, reliable, and cost-effective.

Availability of Nickel Raw Materials

Nickel is a vital component in the production of many everyday items, including batteries, coins, and even stainless steel. However, the availability of raw nickel materials has become a concern in recent years. While nickel is abundant in the Earth’s crust, its extraction and refinement can be costly and environmentally damaging.

In addition, the increasing demand for electric vehicles and renewable energy storage solutions has put pressure on the supply chain of nickel raw materials. To address this issue, exploration and development of new nickel deposits are underway, alongside efforts to improve the efficiency of nickel extraction and refining processes. Recycling and reusing nickel is also becoming more common to reduce reliance on newly mined materials.

Despite the challenges posed by the availability of nickel raw materials, industry players are actively working towards solutions to ensure a sustainable supply for future demand.

Nickel Mining and Environmental Concerns

Nickel mining is a booming industry, but with it comes environmental concerns. The extraction of nickel from the earth can have devastating effects on the nearby ecosystems, disrupting aquatic life and causing soil erosion. Additionally, the mining process requires large amounts of water, potentially leading to water scarcity in the surrounding communities.

On top of that, nickel mines can release harmful chemicals and greenhouse gases into the air, contributing to climate change and health problems for nearby residents. While advancements have been made in reducing the environmental impact of nickel mining, it is important to continue finding ways to minimize the harm and preserve the delicate balance of our planet’s ecosystems. As consumers, we can also play a role by supporting companies that prioritize sustainability and responsibly sourced materials.

Conclusion

In conclusion, the raw materials needed for electric car batteries may seem simple on the surface, but the science behind harnessing their power is anything but. From the lithium-ion batteries to the rare earth metals, the innovation and technology that goes into creating these materials is impressive. It’s amazing to see how much we’ve progressed over the years in terms of sustainable and eco-friendly transportation.

So, next time you plug in your electric vehicle to charge, remember the complex chemistry and materials that make it all possible!”

Importance of Investing in Sustainable Raw Materials

Nickel is a critical raw material used in many industries such as aerospace, batteries, and electronics. The importance of investing in sustainable nickel cannot be overstated. Nickel production has a significant environmental impact due to its high energy consumption and greenhouse gas emissions.

However, sustainable mining practices and the use of recycled nickel can significantly reduce its environmental impact. Additionally, the demand for nickel is expected to increase dramatically in the coming years due to the rise of electric vehicles and renewable energy storage systems. Therefore, investing in sustainable nickel mining and production is essential for meeting the growing demand without causing environmental harm.

Companies that prioritize sustainable nickel production will not only benefit the environment but also enhance their reputation and attract socially responsible investors.

FAQs

What are the raw materials used in the production of electric car batteries?

The raw materials commonly used in electric car batteries are lithium, cobalt, nickel, and manganese.

What are the environmental impacts associated with the production of electric car batteries?

The production of electric car batteries requires significant amounts of energy and can result in the release of greenhouse gases. Additionally, the mining and sourcing of raw materials for the batteries can have negative environmental impacts.

How do electric car batteries compare to traditional gasoline-powered car batteries in terms of lifespan?

Electric car batteries generally have a longer lifespan than traditional gasoline-powered car batteries and can last for up to 10 years or more.

Are there any safety concerns associated with electric car batteries?

Electric car batteries can pose a risk of fire or explosion if they are damaged or improperly handled, but overall they are considered to be safe if they are manufactured and used correctly.