The Shocking Truth Behind the Electric Car Battery Shortage of 2018: What You Need to Know

Are you considering buying an electric car? If so, you’re not alone. Many people are making the switch to electric vehicles as a way to reduce their carbon footprint and save on gas costs. However, there is currently a major obstacle facing the electric car industry: a battery shortage.

In 2018, the demand for electric car batteries far outweighed the supply. This shortage has caused delays in production and forced automakers to cut back on the number of electric cars they produce. The shortage has also led to a spike in battery prices, making electric cars more expensive than they would be otherwise.

Despite this setback, experts predict that the electric car market will bounce back. As technology continues to improve and battery production becomes more efficient, the supply of electric car batteries is expected to meet the growing demand. In the meantime, there are still plenty of electric car options available to consumers.

While prices may be higher than usual due to the battery shortage, making the switch to an electric car is still a wise investment in the long run. Not only will you be reducing your impact on the environment, but you’ll also save money on gas and maintenance costs in the long run. So, are you ready to make the switch to an electric car? Despite the current battery shortage, there’s never been a better time to make the leap.

Current State of Electric Car Battery Supply

As electric cars become more popular, there is a growing concern over the supply of electric car batteries. The demand for these batteries is already high, and with more automakers investing in electric cars, the demand is only going to increase. This has led to a shortage of electric car batteries in 2018, leaving some car makers struggling to meet demand.

In some cases, battery manufacturers have even had to turn away customers. However, the good news is that the situation is rapidly improving. New battery factories are being built in the US and elsewhere, which will help to increase supply, and battery technology is also improving, which means that future batteries will be more powerful and last longer.

So, while there may be a short-term supply issue, the long-term outlook for electric car batteries looks very promising.

Global production vs demand for electric car batteries

The current state of the global production and demand for electric car batteries is interesting. On one hand, automakers are ramping up production of electric cars, which require large quantities of batteries. On the other hand, battery manufacturers are struggling to keep up with demand, resulting in shortages and price increases.

As a result, countries are racing to secure their supply chains and invest in domestic battery production. However, this transition takes time, as battery factories require significant investment in infrastructure and technology. It’s like building a house from scratch – it takes time to lay the foundation and construct the walls before the finished product is ready.

Nevertheless, the demand for electric cars and their batteries will only continue to grow, as governments push for cleaner transportation and consumers become increasingly aware of the impact their purchases have on the environment. Overall, the transition to electric cars will require a massive effort from all stakeholders, but it’s a step in the right direction towards a more sustainable future.

Impact of bottlenecking on electric vehicle production

The current state of electric car battery supply is one of the biggest bottlenecks for the production of electric vehicles. The demand for EV batteries is high, but the supply does not keep up. This demand-supply gap leads to increased prices for EV batteries and longer waiting periods for EVs.

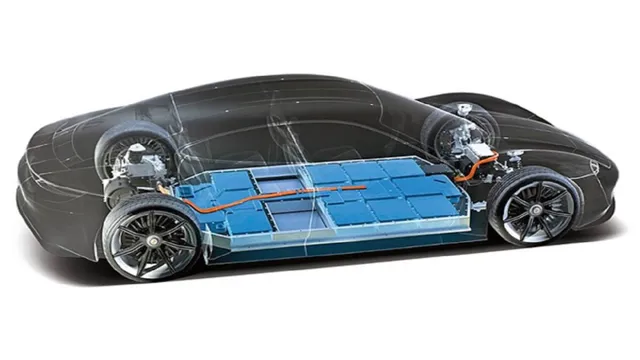

Additionally, the production of EV batteries requires rare materials, such as lithium, cobalt, and nickel. The extraction of these materials entails environmental and social challenges, including exploitation and labor rights violations. This bottlenecking effect sets off a chain reaction in the production process, where other EV components are affected due to unavailability of the battery.

This impacts the entire EV supply chain and complicates the transition to electric vehicles. Addressing the issue of battery supply bottlenecking is crucial to accelerate the transition to a more sustainable future.

Reasons for the Shortage

The electric car industry is currently facing a shortage of batteries. But why is this happening? Well, there are a few reasons. Firstly, there has been a surge in demand for electric cars in recent years, especially in China, which is the largest market for EVs.

This has put pressure on battery manufacturers to keep up with the demand. Secondly, the materials needed to make electric car batteries, such as lithium and cobalt, are finite resources and can be difficult and expensive to obtain. Finally, the COVID-19 pandemic has disrupted global supply chains and caused delays in the production and delivery of batteries.

All of these factors have contributed to the current shortage of electric car batteries in 2018 and beyond. As the demand for electric cars continues to grow, it is crucial that the industry works to find solutions to these problems and ensure a sustainable supply of batteries in the future.

Rise in demand due to government incentives and environmental concerns

One of the key reasons for the current shortage of semiconductors is the rise in demand, which is largely driven by government incentives and environmental concerns. With governments around the world pouring money into next-generation technologies like electric vehicles, renewable energy and 5G, demand for semiconductors has skyrocketed. At the same time, a growing number of consumers are becoming more environmentally conscious, opting for greener technologies that require more electronic components.

This shift in consumer behavior has led to an increased demand for semiconductors in various electronic devices, from laptops and smartphones to TVs and game consoles. As a result, manufacturers are struggling to keep up with the pace, leading to shortages and delays in product availability. Despite efforts to ramp up production, it will likely take some time before the supply chain catches up with demand and the semiconductor shortage comes to an end.

Limited capacity of battery manufacturers

One of the main reasons for the current battery shortage can be attributed to the limited capacity of battery manufacturers. Surprisingly, the demand for electric vehicles and other battery-powered devices has been skyrocketing in recent years, leaving manufacturers struggling to keep up with the demand. This has put a strain on the supply chain, resulting in a shortage of the raw materials used to manufacture batteries.

Additionally, the global pandemic has further exacerbated this problem, causing production delays and disruptions throughout the industry. While manufacturers are taking steps to increase production capacity, it may take some time before the battery shortage is fully resolved. In the meantime, consumers may have to wait longer for their electric vehicles or settle for alternative power sources.

Consequences of the Shortage

The electric car battery shortage of 2018 had many consequences on the industry. Some automakers had to limit production of their electric vehicles due to the lack of batteries, resulting in longer wait times for consumers. Additionally, the shortage caused a spike in the price of lithium, which is a key component in electric car batteries.

This made it difficult for smaller automakers to compete with larger companies who could afford to pay the higher prices. Another consequence of the shortage was that it slowed down the development of new electric vehicle models. Some automakers were forced to delay the release of new models until they could secure enough batteries to meet demand.

However, the shortage also highlighted the need for a more sustainable solution when it comes to battery production and recycling. As the demand for electric vehicles continues to grow, it is important for the industry to find ways to increase battery production and recycling capabilities.

Delays and longer wait times for electric vehicle delivery

The shortage of semiconductor chips has been affecting the automotive industry for quite some time now. One of the most visible consequences is the delay in electric vehicle delivery, which is causing longer wait times for customers. This situation is frustrating for both buyers and sellers.

Due to the high demand for EVs and the limited supply of semiconductors, many car manufacturers have to slow down or halt their production. As a result, the customers who ordered their electric vehicles weeks or even months ago may have to wait longer than expected to get their hands on them. This delay also means that dealerships have less inventory to offer, which might lead to lost sales.

The semiconductor chip shortage serves as a reminder of how interconnected the supply chain is, and how a disruption in one area can cause a ripple effect throughout the industry.

Higher prices for electric cars due to reduced supply

As the global demand for electric vehicles continues to surge, the supply of crucial components is struggling to keep up, leading to a shortage in the market. This shortage is causing the price of electric cars to increase significantly, making it difficult for many drivers to make the transition to more sustainable transportation. The consequences of this shortage stretch far beyond the wallets of consumers; it also affects the progression towards a cleaner future.

The limited availability of electric vehicles means that gasoline-fueled cars will continue to dominate the market, further exacerbating issues of air pollution and climate change. If we hope to reach our sustainability goals, it is crucial that we address this supply issue and find efficient solutions to improve electric vehicle manufacturing.

Future Expectations and Solutions

Electric car enthusiasts have been booming in 2018, but so has the problem of electric car battery shortage. As electric car demand continues to rise significantly, the production of batteries is falling behind. However, the future of electric cars looks promising with the expected solutions to the battery shortage.

Several new battery factories have been built, and many more are expected to be constructed in the upcoming years. Moreover, changes in the battery technology like solid-state batteries with a higher energy density and faster recharge time are anticipated to enter the market and promote replacing old ones. By mass-producing these batteries, the cost of production will decrease, making electric vehicles more affordable and ending the shortage.

Therefore, we can expect the battery crisis for electric cars to be resolved shortly, as new technology is increasing the efficiency of the batteries, and many major automakers are investing in producing electric vehicles in large quantities, driving down battery costs and making these cars much more accessible to the public. Ultimately, the electric car revolution is coming, and these recent developments show that they will be the future.

Plans for expanding battery production capacity

As the demand for electric vehicles continues to rise, battery production capacity needs to be expanded to meet the ever-increasing need for energy storage. Many companies are investing in new production facilities and researching innovative solutions to help achieve this goal. One such company is Tesla, which plans to construct new factories to manufacture the latest and most efficient batteries.

The company has already announced plans to build a factory in Germany, which will produce batteries for the European market, and another in Texas, which will manufacture the new 4680 cells. These new cells feature improvements in energy density, longevity, and cost-effectiveness, making them the perfect choice for the next generation of electric vehicles. Tesla is also working on improving the production process through automation, which will further enhance efficiency and lower costs.

Overall, Tesla is making great strides in expanding battery production capacity to meet the demands of the future.

Exploration of alternative battery technologies

As the demand for more sustainable and efficient energy sources grows, lithium-ion batteries may soon be replaced by alternative battery technologies. One promising alternative is the solid-state battery, which uses solid electrolytes instead of liquid ones to increase energy density and improve safety. Another option is the sodium-ion battery, which holds promise for larger-scale energy storage, as sodium is abundant and inexpensive.

Other researchers are exploring the potential of organic batteries, which can use renewable resources and have a smaller environmental impact. As we continue to advance in battery technology, it is important to consider not just the practicality and efficiency, but also the sustainability of these alternatives. By embracing these new developments and exploring even more innovative solutions, we can pave the way towards a truly clean and reliable energy future.

Potential impact on the transition to fully electric vehicles

The transition to fully electric vehicles has been on the rise, with more countries and automakers committing to this technology. However, the potential impact of this shift remains a topic of debate. On the one hand, the widespread adoption of electric vehicles can significantly reduce carbon emissions, decrease the reliance on fossil fuels, and improve air quality in cities.

On the other hand, the infrastructure for charging electric vehicles is still developing, and the cost of electric vehicles is often higher than their gas-powered counterparts. Despite these challenges, there are reasons to be optimistic about the future of electric vehicles. One potential solution is the development of better battery technology.

As battery costs decrease, electric vehicles will become more affordable and practical. Furthermore, improvements in charging infrastructure, including fast-charging stations and wireless charging technology, will help overcome range anxiety and make it easier for electric vehicle owners to charge their vehicles on the go. Another solution is to provide financial incentives to encourage consumers to switch to electric vehicles.

Governments and automakers can offer tax credits, rebates, and other incentives to make electric vehicles more affordable and accessible. This can accelerate the transition to fully electric vehicles and help build the necessary infrastructure to support this shift. In summary, the transition to fully electric vehicles has the potential to bring significant benefits, not only to the environment but also to public health and energy security.

While there are challenges to overcome, the development of better battery technology, improvements in charging infrastructure, and financial incentives can help accelerate this transition and make electric vehicles a viable and practical option for consumers.

Conclusion

In conclusion, the electric car battery shortage of 2018 can be seen as both a challenge and an opportunity. While it may have exposed limitations within the industry, it also serves as a reminder that the transition towards sustainable transportation is not happening overnight. Patience and innovation will be key in order to overcome this issue, and to continue towards a future of cleaner and more efficient mobility.

As they say, when life hands you a battery shortage, make lemonade…or rather, make a breakthrough in energy storage technology!”

FAQs

What is causing the electric car battery shortage in 2018?

The shortage is primarily due to a surge in demand for electric vehicles and limited production capabilities of battery manufacturers.

How long is the average wait for an electric car battery replacement in 2018?

The wait time for a battery replacement varies depending on the specific make and model of the electric vehicle. In some cases, it may take several weeks or even months to receive a new battery.

Are there any alternatives to electric car batteries in 2018?

While lithium-ion batteries are currently the most popular choice for electric vehicles, there are alternative battery technologies being developed, such as solid-state batteries and flow batteries.

Can electric car batteries be recycled in 2018?

Yes, electric car batteries can be recycled. The recycling process typically involves removing valuable metals such as lithium, cobalt, and nickel and reusing them in new batteries or other applications.