Rev Up Your Ride with an Electric Boost: How a 12V Car Battery Charger Powered by an Electric Motor Can Keep You on the Road

If you’re an avid car enthusiast or someone who’s always looking for DIY projects, creating a 12V car battery charger from an electric motor might be the perfect project for you. Not only is it a fun and rewarding experience, but it also provides a practical use for your car batteries. Who knows, it might even save you from a dead car battery in the future.

In this blog post, we’ll guide you through the steps on how to create your own 12V car battery charger using an electric motor. Get ready to roll up your sleeves and let’s dive in!

Understanding the Basics of Car Battery Charging

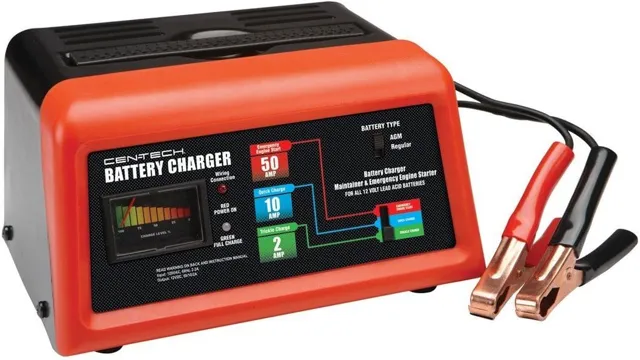

If you’re looking for a way to charge your car battery using an electric motor, you’ll need a 12v car battery charger that’s equipped with this capability. Such chargers are designed to convert AC power from a wall outlet into DC power, which is needed to charge your car battery. The charger works by sending electric current into the battery, which is then stored as chemical energy.

Over time, the chemical energy is converted back into electrical energy that your car can use to run its various systems. Remember to always follow the manufacturer’s instructions when using a 12v car battery charger with an electric motor to ensure the safety and longevity of your battery. With the right equipment and a basic understanding of how the charging process works, you can keep your car running smoothly and reliably for years to come.

How a Car Battery Works

Car battery charging Have you ever wondered how your car battery works? Well, it’s a crucial part of your vehicle’s electrical system, converting chemical energy into electrical energy to power your car’s electronics and start the engine. The battery stores this energy and delivers it to the starter motor and the rest of the electrical system when you turn the key. But how does it get charged? When your car’s engine is running, the alternator takes over to provide electrical power and recharge the battery.

The alternator uses the engine’s rotational energy to generate an alternating current, which is then converted into direct current by the rectifier. This direct current is sent to the battery, topping it up and maintaining its charge. It’s essential to keep your battery charged to ensure you don’t get stranded with a dead battery and to prolong its life.

In summary, understanding the basics of car battery charging is crucial to ensure optimal function and longevity.

Charging a Car Battery with an Electric Motor

To understand how to charge a car battery with an electric motor, you first need to grasp the basics of car battery charging. Every vehicle comes with an alternator that charges the battery as the engine runs. It generates electricity that powers the car’s electrical components and charges the battery simultaneously.

However, if your battery is dead, you may need a backup source to charge it, such as an electric motor. An electric motor can be an alternative power source in an emergency, but it’s not a primary solution to charging your car battery. That’s why it’s essential to have a battery charger or an alternative source of power on hand in case of a dead battery, rather than relying solely on an electric motor.

Materials Needed for a DIY Car Battery Charger

If you’re looking to create your own 12V car battery charger using an electric motor, there are a few materials you’ll need to gather before getting started. First, you’ll need to acquire an electric motor that is capable of generating enough power to charge a car battery. Additionally, you’ll need a rectifier, which will help convert the AC voltage produced by the motor into the DC voltage that your car battery needs.

You’ll also need a voltage regulator, which will help ensure that the charging voltage stays within a safe range. Other materials you may need include a power switch, a fuse, and some wiring. With these materials in hand, you’ll be ready to start building your own DIY car battery charger that can help keep your car’s battery in optimal working condition!

Electric Motor

If you’re looking to create a DIY car battery charger using an electric motor, then you’ll need a few materials to get started. Firstly, a rectifier is essential to convert the AC power from the electric motor into DC power, which is what your car battery needs. You’ll also need a voltage regulator to prevent overcharging and damage to your battery.

A capacitor is necessary for smoothing out any voltage spikes that could damage your battery. A relay switch is another handy component to have as it allows you to turn off the charger automatically once your battery is fully charged. The last material you’ll need is a charging cable with alligator clips to connect to your car battery.

With these essential materials, you can create a safe and effective DIY car battery charger using an electric motor. So, why not give it a try and recharge your car battery using renewable energy?

Rectifier Bridge

If you’re looking to build your very own car battery charger, then it’s essential that you have a rectifier bridge on hand. This crucial component is responsible for converting the alternating current (AC) power from your outlet into direct current (DC) power that’s necessary for charging your car battery. Without this component, your charger will not be able to provide the proper voltage or current needed to charge your battery efficiently.

The rectifier bridge is made up of four diodes that work together to change the polarity of the AC power, allowing it to flow in only one direction. It’s important to ensure that the diodes you use are capable of handling the power requirements of your battery charger, so be sure to do your research before selecting the right components for your project. Overall, having a rectifier bridge is essential for building a reliable and efficient car battery charger, making it a crucial part of any DIY project for automotive enthusiasts.

Capacitors

Capacitors If you’re into DIY projects, then building a car battery charger is something you might be interested in. You’ll need a few materials to get started, including capacitors. Capacitors are essential for storing electrical charge and releasing it when needed.

When it comes to car battery chargers, you’ll need capacitors that can handle high voltage and current. Tantalum and aluminum electrolytic capacitors are good options to consider as they can handle high voltage and are relatively inexpensive. However, tantalum capacitors are more expensive than aluminum electrolytic capacitors but can handle higher temperatures.

When choosing capacitors, it’s essential to consider the voltage and current ratings as they will affect the efficiency of your battery charger. Capacitors are just one piece of the puzzle when it comes to building a DIY car battery charger, but they are a crucial piece in ensuring your charger is efficient and can handle high voltage and current.

Diodes

Diodes Are you tired of having to jump-start your car every time you forget to turn off the lights? Building a DIY car battery charger is easier than you think, and can save you both time and money in the long run. To get started, you’ll need a few materials, including diodes. Diodes are a kind of semiconductor that only allows current to flow in one direction – perfect for protecting your battery from any harmful reverse current.

When selecting diodes for your charger, make sure they can handle the amount of current your battery requires. It’s also important to choose the right voltage rating, to match that of your battery. With the right materials and a little bit of know-how, you’ll be able to keep your car charged and ready to go whenever you need it.

Step-by-Step Guide to Building a 12V Car Battery Charger

Looking for a way to keep your car battery charged without having to constantly replace it? Consider building your own 12V car battery charger using an electric motor. This step-by-step guide will help you get started. First, gather all the necessary materials, including a 12V battery, an electric motor, a voltage regulator, and some wires.

Next, connect the positive terminal of the battery to the positive terminal of the motor, and the negative terminal of the motor to the negative terminal of the battery. Then, attach the voltage regulator to the motor, and connect the regulator to a power source. Finally, turn on the power and let the charger do its job.

With a little bit of effort and the right materials, you can build your own 12V car battery charger and save money in the long run.

Step 1: Assembling the Components

To build a 12V car battery charger, the first step is to assemble the necessary components. You will need a power transformer, a diode bridge rectifier, capacitors, resistors, an ammeter, a voltmeter, a fuse, and alligator clips. These components can be found at an electronics store or online.

Once you have all the components, you can begin assembling the charger. It’s important to follow the instructions carefully to ensure that the charger is built safely and efficiently. Start by connecting the transformer to the diode bridge rectifier, which will convert AC current to DC current.

Then, connect the capacitors and resistors to regulate the voltage and current. Finally, connect the ammeter and voltmeter to monitor the charging process, and add the fuse for protection in case of a short circuit. With these components assembled, your 12V car battery charger is ready for use.

Step 2: Connecting the Rectifier Bridge

In Step 2 of building our 12V car battery charger, we need to connect the rectifier bridge. But what is a rectifier bridge? Simply put, it’s a device that converts alternating current (AC) into direct current (DC), which is what we need to charge a car battery. The rectifier bridge consists of diodes that allow current to flow in only one direction, effectively changing the AC input into DC output.

To connect the rectifier bridge, we need to first identify the positive (+) and negative (-) terminals. Then, using a soldering iron, we can attach the wires from the AC source to the appropriate terminals on the bridge. It’s important to make sure the connections are secure and there are no loose wires that could cause a short circuit.

Once the rectifier bridge is connected, we’re one step closer to completing our battery charger and getting our car back on the road!

Step 3: Wiring the Capacitors

When it comes to building your own car battery charger, wiring the capacitors is the next crucial step to take. Capacitors are essential for storing and releasing energy to make sure your battery receives the correct amount of voltage. To wire your capacitors, you need to connect the positive lead from the first capacitor to the negative lead of the second capacitor.

Then connect the positive lead of the second capacitor to the negative lead of the third capacitor, and so on until you have connected them all in series. It is important to double-check that all the connections are secure and free from any loose wires or stray strands. Once your capacitors are correctly wired, you are ready to move on to the next part of your car battery charger build and continue building it to ensure it functions correctly.

Step 4: Adding Diodes and Connectors

When it comes to building a 12V car battery charger, adding diodes and connectors is a crucial step. Diodes are important because they ensure that the current flows in the right direction, preventing the battery from discharging when there is no power input. They also protect the battery from reverse polarity, which can damage it.

Connectors, on the other hand, are essential for connecting the charger to the battery and making sure that the power is flowing smoothly. When attaching connectors, it’s important to make sure that they are securely fastened, so that there is no risk of accidentally disconnecting them while the charger is in use. Adding diodes and connectors may seem intimidating at first, but with careful attention to detail and a little bit of practice, it can be a relatively easy and straightforward process.

So if you’re building your own 12V battery charger, be sure not to skip this important step, and take the time to get it done right.

Step 5: Testing the Charger

After completing all the necessary steps to build a 12V car battery charger, it’s important to test the charger before use. First, connect the charger to your car battery and switch it on. Check if the LED lights illuminate and see how long it takes for the charger to charge the battery.

Ensure that the battery doesn’t overheat or emit any unusual sounds. Test it again on another car battery to confirm its effectiveness. Keep in mind the charger’s voltage and amperage specifications to avoid any accidents or damage to your car battery.

It’s always better to be safe than sorry, so take your time to test the device thoroughly before relying on it to charge your car battery. With a properly functioning charger, you can prevent unexpected car battery failures and keep your vehicle running smoothly.

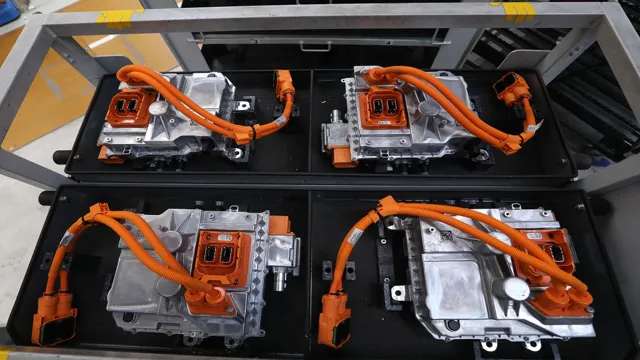

Advantages of Using an Electric Motor for Car Battery Charging

Using an electric motor for car battery charging has several advantages. One of the main benefits is the efficiency it offers. Unlike traditional battery chargers, electric motors do not generate a lot of heat when charging, which means that less energy is wasted, resulting in a faster charging time.

Additionally, electric motors are more eco-friendly than gas-powered motors, making them an environmentally conscious choice. Another advantage is the ease of use and accessibility. Electric motors can be easily installed and used at home, eliminating the need to take your car to a service station.

Therefore, investing in a 12v car battery charger using an electric motor is a smart choice for anyone looking for a cost-effective, sustainable, and convenient way to charge their car battery.

Efficiency and Low Cost

Electric Motor Using an electric motor to charge your car battery can be a more efficient and cost-effective option compared to traditional methods. Electric motors convert electrical energy into mechanical energy, which can then be used to charge your car battery. Since electricity can be produced from renewable sources such as solar or wind power, using an electric motor for charging can also be a cleaner and more sustainable option.

Additionally, electric motors have fewer moving parts compared to internal combustion engines, which reduces the likelihood of breakdowns and maintenance costs. Overall, using an electric motor for car battery charging can be a smart choice both financially and environmentally.

Portable and Lightweight

One advantage of using an electric motor for car battery charging is that it is portable and lightweight. This means that the motor can be easily transported and used in various locations without the need for heavy lifting or specialized equipment. In addition, it can be more energy-efficient, allowing for faster charging times and reducing overall energy consumption.

This is especially beneficial for those who frequently travel long distances and need to charge their car batteries on the go. With the ability to charge a car battery quickly and efficiently, electric motors are becoming a popular choice for many car owners looking to save time and money while reducing their environmental impact. So why not make the switch to an electric motor today and experience the convenience and benefits for yourself?

Conclusion

In conclusion, the 12v car battery charger using an electric motor is a genius invention that combines efficiency and eco-friendliness. By utilizing electricity instead of gasoline or other fossil fuels, we not only save money but also reduce harm to the environment. It’s like killing two birds with one stone, but in a good way.

Let’s charge our batteries with electricity and take care of our planet at the same time!”

FAQs

What is a 12v car battery charger?

A 12v car battery charger is a device used to recharge car batteries that have lost their power or gone flat.

How does an electric motor help in a 12v car battery charger?

An electric motor is used in a 12v car battery charger to generate the necessary electrical energy required to recharge car batteries.

Can a 12v car battery charger be used for other applications besides cars?

Yes, depending on the model, a 12v car battery charger can be used to recharge batteries for other vehicles such as motorcycles, boats, and lawnmowers.

How long does it take to fully charge a car battery using a 12v car battery charger?

The time it takes to fully charge a car battery using a 12v car battery charger depends on the size and condition of the battery. On average, it can take anywhere from 4 to 24 hours to fully charge a car battery.