The Dangerous Reality of Toxic Battery Manufacturing for Electric Cars

Electric cars are seen as the solution to many problems that come with traditional gas-powered vehicles. They have zero emissions, they are quiet, and they could potentially reduce our carbon footprint. However, as with any solution, there are always consequences.

One major issue that often goes overlooked in the conversation around electric cars is the dark reality of battery manufacturing. While electric car batteries may seem like a promising innovation, the production process comes at a significant environmental cost. The toxic chemicals and hazardous materials involved in the production of batteries make it difficult to justify the benefits of electric cars.

As electrification becomes more widespread, the demand for batteries is only going to rise, which means even more mining, processing, and manufacturing of batteries. It begs the question, is it really worth the environmental costs of producing electric car batteries? In this article, we will delve into the complex issue of battery manufacturing for electric cars, examining the environmental impacts and ethical considerations that need to be taken into account. While the conversation surrounding electric cars often focuses on the benefits they bring, we must also acknowledge the darker side of this technology.

Environmental Impact

It’s no secret that the production of batteries for electric cars has a significant environmental impact. The manufacturing process includes the extraction of minerals like lithium and cobalt, which are typically mined in ways that damage ecosystems and harm local communities. Further, the chemicals used in battery production are toxic and can contaminate soil and water sources.

This can have dire consequences for both the environment and human health. While electric cars may be carbon-neutral during use, their production process is far from it. As with any new technology, it is essential to consider the full lifecycle of electric cars, including their manufacturing and disposal.

While battery production is necessary to meet the increasing demand for electric cars, manufacturers should work to minimize their environmental impact through responsible sourcing and recycling practices. Until then, it’s important to acknowledge the environmental costs of electric car batteries and work towards more sustainable alternatives.

Toxic Chemicals Used in Battery Production

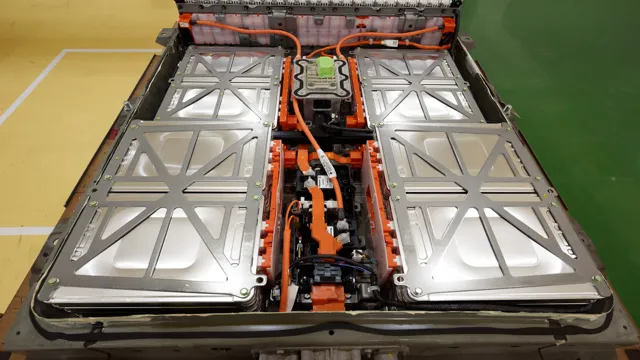

The production of batteries involves a number of toxic chemicals that have an adverse effect on the environment. For instance, lead-acid batteries contain lead and sulfuric acid, both of which are highly toxic and can contaminate the soil and water if not disposed of properly. Similarly, lithium-ion batteries contain cobalt, nickel, and other rare metals that are extracted through destructive mining processes.

The mining activities release hazardous gaseous emissions that contribute to air pollution, and the waste materials are often disposed of irresponsibly, leading to land degradation and water pollution. It is therefore essential to implement responsible practices in the production and disposal of batteries to minimize their environmental impact.

Mining for Battery Materials Releases Hazardous Waste

Mining for battery materials is a complex process that has a significant environmental impact. While fossil fuels like oil and gas have dominated the conversation on environmental damage, the production of batteries for electric vehicles and renewable energy storage is often overlooked. The process of mining for materials like lithium, cobalt, and nickel involves the use of heavy machinery and the release of hazardous waste into the air and water sources.

This waste contains chemicals that can harm aquatic and terrestrial ecosystems, including humans. In addition to the physical damage caused by mining, there is also a social impact to consider as indigenous communities are often displaced from their land. As we move towards a more sustainable future, it is important to prioritize the responsible sourcing and recycling of battery materials to minimize the detrimental effects on the environment and society.

Human Health Impact

Battery manufacturing for electric cars is a complex and intricate process. While electric vehicles offer significant benefits such as reduced emissions and improved fuel economy, the batteries used to power these cars can have a negative impact on human health and the environment. The process of manufacturing batteries for electric cars involves the use of toxic chemicals such as lead, nickel, and cobalt.

These chemicals are not only harmful to those who work in the manufacturing plants but also to those who live near them. Exposure to these chemicals can lead to respiratory problems, neurological damage, and even cancer. In addition, the disposal of used batteries can pose a significant environmental hazard.

While efforts are being made to make battery production and disposal cleaner and more sustainable, it is essential to acknowledge the potential risks associated with battery manufacturing for electric cars.

Exposure to Toxic Chemicals Presents Health Risks

Exposure to toxic chemicals can have significant and long-lasting impacts on human health. These harmful chemicals can come from numerous sources, including air pollution, contaminated water, and exposure at home or in the workplace. When individuals are exposed to toxic chemicals, they can experience a wide range of negative health effects, including irritation of the skin, eyes, and respiratory system, as well as damage to internal organs.

More severe health risks can include cancer, reproductive and developmental problems, and neurological damage. It’s important to understand the dangers of toxic chemical exposure and take steps to protect ourselves and our loved ones by reducing our exposure to harmful chemicals through safer work practices, healthy lifestyle choices, and proper disposal of hazardous waste materials. By taking these preventive measures, we can help ensure a healthier, safer future for ourselves and generations to come.

Workers in Battery Production Factories at Risk

It has been reported that workers in battery production factories are at risk of adverse health effects. It is well-known that this industry uses hazardous chemicals and materials, including lead, cadmium, and other heavy metals, which can cause harm to human health if not handled correctly. Unfortunately, many workers are not provided with appropriate safety gear or training on how to minimize exposure to these toxic substances.

As a result, they can suffer from a variety of health problems such as respiratory issues, skin conditions, and even cancer. This undoubtedly highlights the need for manufacturers to prioritize the health and safety of their employees, and for governments to regulate this industry to ensure workers are protected. Overall, it is crucial that we acknowledge the human impact of battery production and take action to prevent harm.

Communities Near Battery Plants Exposed to Hazardous Pollution

Battery plants emit hazardous pollution that can be harmful to human health. Communities located near these plants are especially vulnerable to the negative effects of this pollution. The emissions from battery plants contain toxic chemicals, such as lead, cadmium, and sulfuric acid, which can cause respiratory issues, headaches, nausea, and other health problems.

Inhaling these chemicals can damage the lungs and lead to long-term health impacts. Because battery plants require large amounts of electricity to operate, they often emit large amounts of greenhouse gases, contributing to climate change and further impacting human health. It’s crucial for communities located near battery plants to be aware of the risks associated with living near these facilities and advocate for stronger regulations to protect public health.

Ethical Considerations

When it comes to the future of transportation, electric cars are often touted as the environmentally-friendly alternative to traditional gas-guzzlers. However, one aspect of electric cars that is frequently overlooked is the toxic nature of the battery manufacturing process. Battery manufacturing for electric cars involves the use of materials such as lithium and cobalt – materials that can be harmful not only to the environment but also to the people involved in the production process.

This raises important ethical considerations when it comes to the production and use of electric cars. As consumers, we must question whether the overall benefits of electric cars are worth the potential harm that may be caused during production. Alternatively, we can push for ethical and sustainable practices to be implemented in battery manufacturing in order to create a more positive impact on both people and the environment.

Are Electric Cars Really the Solution?

When it comes to electric cars as a solution for environmental and sustainability issues, we should consider the ethical implications of their production. While electric cars produce less emissions on the road compared to traditional cars, the production process for electric vehicle batteries relies heavily on mining and extracting rare minerals, such as cobalt and lithium. The mining industry responsible for sourcing these minerals is largely unregulated and can lead to the exploitation of local communities and workers, as well as environmental damage.

In addition to the ethical concerns surrounding the production of electric cars, we should also consider the issue of disposal and recycling of the batteries. Proper disposal and recycling processes can be expensive and difficult to implement, leading to potential negative environmental impacts. Overall, while electric cars offer some promise as a solution to our sustainability challenges, it is important to consider the ethical implications of their production and disposal.

Efforts must be made to ensure that the mining and production processes for electric vehicle batteries are conducted in an ethical and sustainable manner, and that proper disposal and recycling processes are implemented. Only then can electric cars truly be considered a solution for our environmental challenges.

Responsibility of Car Manufacturers to Address Battery Production Hazards

The responsibility of car manufacturers to address the hazards associated with battery production is a topic of growing concern. While electric cars are touted as a sustainable and environmentally-friendly alternative to gas guzzlers, the production of their batteries can have negative impacts if not handled responsibly. It is therefore imperative for car manufacturers to prioritize ethical considerations when it comes to producing batteries.

This includes taking steps to minimize the environmental impact of the manufacturing process, as well as protecting the health and safety of workers involved in battery production. Additionally, manufacturers must address the issue of responsible disposal of batteries at the end of their lifespan. Ultimately, the responsibility falls on car manufacturers to ensure that they are not merely shifting the burden of environmental and human harm from the tailpipe to the manufacturing line.

It is their duty to create a truly sustainable and ethical product that benefits both the planet and its inhabitants.

Moving Towards a Greener Future

As the world moves towards a greener future with an increasing focus on electric cars, it’s important to acknowledge the environmental impact of battery manufacturing. The process is known to be environmentally toxic, with harmful chemicals such as lead and lithium being used in the production. This is not only detrimental to the environment but also to the health of those involved in the manufacturing process.

However, as the demand for electric cars grows, manufacturers are being pushed to find more sustainable and environmentally friendly methods of production. One solution is to use recycled materials, which can significantly reduce the environmental footprint of battery manufacturing. In addition, researchers are also exploring the potential for plant-based materials as an alternative, which could provide a more sustainable and renewable source for battery production.

Although there is still much work to be done, it’s encouraging to see the industry moving towards a greener future and taking responsibility for their environmental impact.

Conclusion

It seems that in the quest for eco-friendly transportation, we may have overlooked a crucial detail – the toxicity of battery manufacturing for electric cars. While electric vehicles may emit less harmful chemicals on the road, the process of creating the batteries is far from clean. So let’s not forget that truly sustainable transportation requires a holistic approach, including the responsible sourcing and production of materials.

As they say, the devil is in the details…

and the batteries.”

FAQs

What makes battery manufacturing for electric cars a toxic process?

The process involves mining and processing of materials like lithium and cobalt which can leave behind toxic waste and pose health risks to workers.

Are there any regulations in place to ensure safe battery manufacturing for electric cars?

Yes, there are regulations in place to limit the environmental and health impacts of battery manufacturing, such as proper waste disposal and limiting exposure to hazardous materials.

Do battery manufacturers have any plans to improve the sustainability of their production process?

Yes, many battery manufacturers are investing in research and development to find more sustainable materials and manufacturing processes that reduce the environmental impact of battery production.

How can consumers ensure the batteries in their electric cars were produced sustainably?

Consumers can research and choose electric cars that are produced by manufacturers with strong sustainability and environmental policies and certifications such as the Responsible Battery Coalition or the Global Battery Alliance.