Revolutionizing Electric Cars: The Aluminum Air Battery Technology Development

Electric vehicles have been gaining popularity around the world as an environmentally friendly and cost-effective mode of transportation. However, the limited battery life of electric cars continues to be a major drawback for their widespread adoption. To address this issue, researchers have been exploring various types of batteries that offer longer operating times without being too heavy or expensive.

One such promising technology is aluminum-air batteries that can potentially revolutionize the world of electric vehicles. In this blog, we will delve into the details of aluminum-air batteries and their potential as a game-changer in the electric car industry. So, let’s dive in to learn more!

What are Aluminum Air Batteries?

Aluminum Air Batteries are a developing technology that could revolutionize the way we power electric cars. These batteries rely on the reaction between oxygen and aluminum to produce electricity, making them incredibly lightweight and efficient. Additionally, the aluminum used in the batteries is inexpensive and widely available, making it a cost-effective source of energy.

The process of developing aluminum air batteries is still ongoing, with researchers exploring ways to extend the battery life and increase their energy output. However, if successful, these batteries could be a game-changer for the automotive industry, providing a renewable source of energy that is both affordable and sustainable. As we continue to seek out more environmentally-friendly alternatives to traditional fuel sources, the development of aluminum air batteries presents an exciting possibility for the future of transportation.

Description and Functionality

Aluminum air batteries are a type of metal-air battery that utilizes aluminum as the anode and oxygen as the cathode to generate electricity. These batteries combine the lightweight and abundant nature of aluminum with the high energy density of metal-air technology, making them a promising option for large-scale energy storage. When aluminum is exposed to the air, it forms a layer of aluminum oxide, which can react with the electrolyte to release electrons and generate electricity.

The main advantage of aluminum air batteries is their high energy density, which makes them an attractive option for transportation and other high-energy applications. However, these batteries still face challenges such as efficiency and longevity, and further research is needed to fully optimize their performance. Overall, aluminum air batteries provide a promising avenue for renewable energy storage and have the potential to become a major player in the energy storage market.

Advantages of Aluminum Air Batteries

With the development of aluminum air batteries, the potential for electric cars to become even more efficient and sustainable is being realized. Aluminum air batteries have several advantages over traditional lithium-ion batteries. For one, they are significantly lighter and have a longer lifespan due to their higher energy density.

They also have a higher energy-to-volume ratio, making them more compact and easier to fit into an electric car’s limited space. Additionally, aluminum is abundant and inexpensive, making these batteries more cost-effective to produce. Finally, aluminum air batteries are environmentally friendly since they use oxygen from the air instead of relying on toxic materials.

In conclusion, the development of aluminum air batteries is a promising step toward making electric cars even more environmentally friendly and efficient.

Sustainability and Environmental Impact

As the world moves towards a more sustainable future, the use of aluminum air batteries presents many advantages. Unlike traditional batteries, aluminum air batteries rely on the reaction of aluminum and oxygen to produce electricity, without the need for toxic chemicals. This makes them a highly eco-friendly option as they do not release any harmful emissions during their operation or disposal.

Additionally, aluminum is a widely available and affordable material, making the production of these batteries economically viable. Their high energy density and long-lasting power also provide a reliable and low-maintenance source of energy for a range of applications, from electric cars to remote off-grid locations. By embracing the use of aluminum air batteries, we are taking a positive step towards reducing our reliance on non-renewable resources and decreasing our environmental impact.

Cost and Efficiency

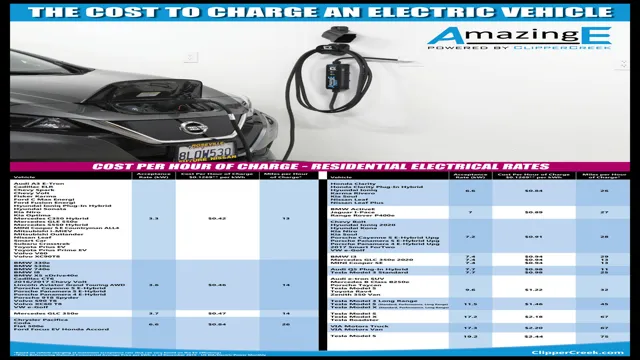

When it comes to batteries, cost and efficiency are two crucial factors. Aluminum air batteries come with some significant advantages. They have low production costs since aluminum is more affordable than other materials like lithium.

Apart from being cost-effective, aluminum air batteries are also highly efficient. They offer high energy density, meaning they can store more energy per unit of weight or volume. Additionally, aluminum air batteries are rechargeable, making them a practical choice for long-term use.

This rechargeability means that they can save costs in the long run since they can be used multiple times before being replaced. Overall, the cost-effectiveness and high efficiency of aluminum air batteries make them a promising solution for sustainable energy storage.

Limitations and Challenges

Developing an aluminum air battery towards powering an electric car is not without its limitations and challenges. One of the major limitations is the cost of materials. Aluminum is a relatively expensive material, which can make the batteries pricey.

However, advancements in technology have led to decreased production costs, making it more affordable. Another challenge is the stability of the battery. Aluminum is susceptible to corrosion when exposed to air and moisture, which can limit the lifespan of the battery.

Research is ongoing to find ways to improve the stability and longevity of the batteries, such as coatings and processing techniques that reduce corrosion. Additionally, the power output of an aluminum air battery is lower compared to other battery types, which could limit its use in electric cars that require high power output for efficient performance. However, research and development are continuously being conducted to address these limitations and challenges, and it is anticipated that aluminum air batteries will play an important role in the future of sustainable transportation.

Durability and Lifespan

When it comes to the durability and lifespan of products, there are a lot of limitations and challenges that manufacturers face. Materials can only withstand so much wear and tear, and it can be difficult to predict how long a product will last under normal use. Factors like user behavior, environmental conditions, and maintenance can all impact a product’s lifespan.

High-tech gadgets, in particular, can be susceptible to issues like battery depletion and software obsolescence. Plus, as technology continues to evolve at a rapid pace, products are becoming increasingly complex, making them harder to repair or replace parts. Nevertheless, companies are continually exploring new materials and technologies to extend the lifespan of their products.

By using durable materials like alloys or carbon fiber and incorporating software updates, they strive to make their products last as long as possible.

Technical and Production Constraints

When it comes to producing any kind of content, there are always limitations and challenges that can arise. Technical and production constraints can be a major hurdle to overcome. For example, if you’re working with a small budget, you may not have access to the latest equipment or technology.

This could limit the quality of your output and make it difficult to compete with larger organizations. On the other hand, if you’re working with a larger budget, you may have more resources but also higher expectations which can put pressure on your team to perform. Another constraint to consider is time.

Tight deadlines can make it challenging to produce high-quality work. At the same time, it’s crucial to ensure that everything is delivered on time and within budget. Ultimately, managing technical and production constraints is about finding the right balance between quality, time, and budget and making the most of your available resources.

Aluminum Air Batteries in Electric Cars

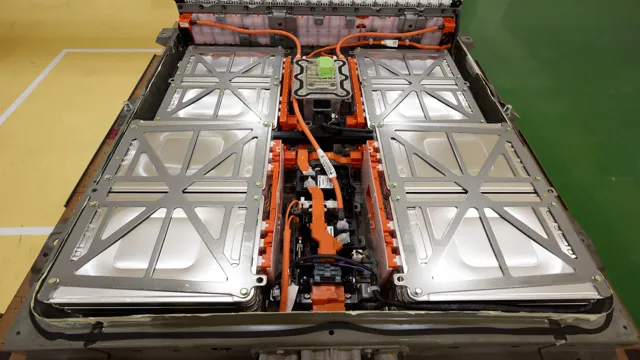

As electric cars continue to gain popularity as a more sustainable mode of transportation, researchers are looking for ways to improve their effectiveness. One promising avenue is the development of aluminum air batteries. These batteries are lightweight, have a high energy density, and can provide extended operating ranges.

In an electric car, they could potentially replace the traditional lithium-ion batteries and provide longer range and faster charging times. There are still challenges to overcome, such as the need to find a way to prevent corrosion, but the development of aluminum air batteries shows promise for the future of electric cars.

Current Development and Research

Aluminum air batteries have been gaining popularity as a potential power source for electric cars. This type of battery works by reacting aluminum with oxygen from the air to generate electricity. One of the benefits of aluminum air batteries is their high energy density, meaning they can store more energy in a smaller space than traditional batteries.

Additionally, aluminum is a highly abundant and low-cost material, making it an attractive option for the automotive industry. However, there are still challenges to overcome before aluminum air batteries can be widely adopted. One issue is the fact that the batteries have a finite lifespan and cannot be recharged like traditional batteries.

Additionally, the reaction between aluminum and oxygen produces aluminum hydroxide, which can clog up the battery and reduce its efficiency over time. Despite these challenges, research is ongoing to improve the performance and reliability of aluminum air batteries, and they could become a promising alternative to traditional batteries in the future.

Potential Impact on Electric Car Industry

Aluminum Air Batteries Possible paragraph: As the electric vehicle market grows, so does the demand for innovative, sustainable, and affordable battery technologies. One promising solution is the aluminum air battery, which uses ambient air as a cathode and metallic aluminum as an anode to generate electricity. This type of battery has several advantages over conventional lithium-ion batteries, such as higher energy density, lower cost, and a non-flammable and recyclable design.

Moreover, the production and distribution of aluminum are already well-established industries worldwide, reducing the supply chain complexity and environmental impact. Thus, aluminum air batteries could potentially revolutionize the electric car industry by extending the driving range, reducing the weight and size of the battery pack, and improving the overall efficiency and performance of the vehicle. However, there are also some challenges to overcome, such as the limited shelf life and rechargeability of the aluminum anode, the need for air filtration and humidity control, and the potential for corrosion and safety issues.

Therefore, further research and development are necessary to optimize the design, materials, and manufacturing processes of aluminum air batteries for mass adoption and commercialization.

Conclusion

In the race towards sustainable transportation, aluminum air batteries hold great promise as a potential game-changer. With their high energy density, lightweight construction, and low cost, these batteries could revolutionize the electric car market, offering longer driving ranges and shorter recharge times. But as with most innovations, there are still obstacles to overcome.

Ongoing research and development is needed to improve the efficiency and durability of these batteries, as well as to tackle issues related to aluminum corrosion and the disposal of spent materials. Nonetheless, with the promise of cleaner, greener mobility on the horizon, we can afford to stay optimistic about the future of aluminum air battery development.”

FAQs

What is an aluminum air battery?

An aluminum air battery is a type of battery that uses aluminum as the anode, oxygen as the cathode, and a water-based electrolyte to produce electricity.

How does an aluminum air battery work?

An aluminum air battery works by using the reaction between aluminum and oxygen to generate electricity. When the battery is charged, aluminum reacts with water to create hydroxide ions and hydrogen gas. At the same time, oxygen is drawn into the battery and reacts with the hydroxide ions to produce electricity.

What are the advantages of using an aluminum air battery in an electric car?

Aluminum air batteries have several advantages, including their high energy density, low cost, and environmental friendliness. They also do not produce any greenhouse gases or harmful pollutants, making them a great alternative to traditional fossil fuel-powered vehicles.

What are some current challenges in the development of aluminum air batteries for electric cars?

One of the main challenges in the development of aluminum air batteries for electric cars is their limited lifespan. The battery can only be discharged once, meaning that it cannot be recharged like a traditional battery. In addition, the water-based electrolyte used in aluminum air batteries can evaporate quickly, which can reduce the battery’s overall performance over time.