Powering the Future: How Aluminum is Revolutionizing Battery Containers in Electric Cars

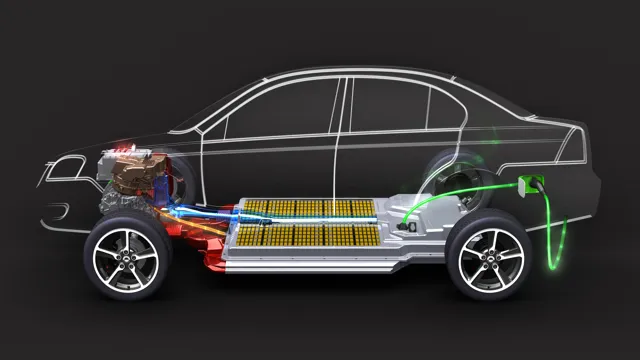

Electric cars are becoming increasingly popular for their eco-friendly nature, as they have the potential to reduce carbon emissions and help combat the growing threat of climate change. However, one of the biggest challenges in the development of electric cars is the creation of efficient and long-lasting batteries. In recent years, aluminum has emerged as a promising material for use in electric car batteries due to its many advantages.

Not only is aluminum lightweight and abundant, but it also has high energy density and is more readily recyclable than traditional battery materials such as lithium. Let’s dive deeper into why aluminum is becoming a go-to material for electric car batteries and what it means for the future of sustainable transportation.

Benefits of Using Aluminum

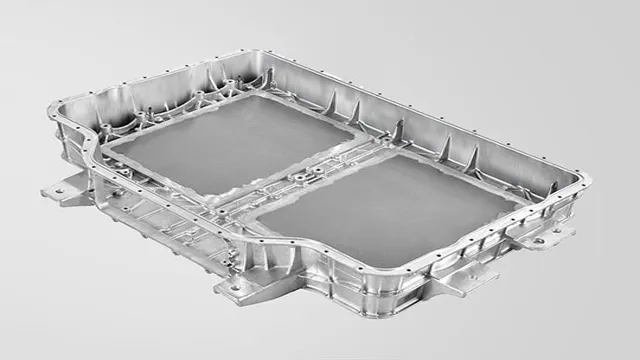

Aluminum is rapidly becoming the material of choice for battery containers in electric cars, and for good reason. First and foremost, aluminum is significantly lighter than other materials traditionally used to create battery containers, making it a top choice for automakers looking to reduce vehicle weight and improve fuel efficiency. Additionally, aluminum is highly resistant to corrosion, which is critical when considering the battery containers’ exposure to potentially harmful elements.

This durability and resistance to wear and tear ensure that the battery containers will last longer and require less maintenance over time. Finally, aluminum is highly recyclable, providing another compelling reason why it’s such an attractive material choice for manufacturers and consumers. This eco-friendly approach is becoming increasingly important in the automotive industry, where sustainability and environmentalism are top priorities.

In summary, the use of aluminum as a material for battery containers in electric vehicles is a win-win, reducing weight, increasing corrosion resistance and life expectancy, and promoting eco-friendliness.

Lightweight

Aluminum is one of the most common materials used in various products because of its lightweight property. With its low density, aluminum is easy to handle and transport, making it an ideal choice for various industries. This metal’s weight benefits not only the manufacturers but also the consumers who buy the products.

For instance, in the automobile industry, using aluminum instead of steel can reduce the car’s weight by up to 60 percent. This lighter car has many advantages, such as increased fuel economy and improved handling and maneuverability. Moreover, aluminum can be molded more easily than other materials, such as steel or iron, allowing manufacturers to create complex shapes and designs more effectively.

As a result, aluminum’s usage in various industries is continuously increasing, and it’s not surprising why this metal has become indispensable to modern-day society.

Durable

When it comes to building materials, aluminum is one of the best options due to its durability and many benefits. Not only is aluminum resistant to corrosion, but it also has a high strength-to-weight ratio, making it a prime choice for structures that need to withstand harsh weather conditions. In addition, aluminum is highly versatile and easy to work with, making it ideal for various applications such as construction, transportation, and even in household items like cookware.

Its malleability allows it to be formed into different shapes and sizes while maintaining its strength, making it a cost-effective and reliable choice in the long-term. Overall, the benefits of using aluminum speaks to its value and durability, making it a top choice for those in need of long-lasting, high-quality materials.

Easy to Shape and Mold

Aluminum is one of the easiest metals to shape and mold, and this is just one of many benefits of using this versatile material. Its unique properties make it an ideal choice for a wide range of applications, from airplanes to soda cans. One of the key advantages of aluminum is its impressive malleability, which allows it to be formed into a variety of shapes and sizes.

This means that manufacturers can create complex designs and intricate structures without having to worry about the limitations of other materials. Additionally, aluminum is lightweight and resilient, making it perfect for use in both industrial and consumer products. Whether you’re looking to create a durable automobile or a lightweight piece of jewelry, aluminum is the perfect choice.

By using this highly adaptable and versatile material, you can create products that are both functional and aesthetically appealing, while also benefiting from increased strength, durability, and longevity. So if you’re looking for a material that is easy to shape and mold, as well as strong and durable, aluminum is definitely your best bet.

Aluminum vs. Other Materials

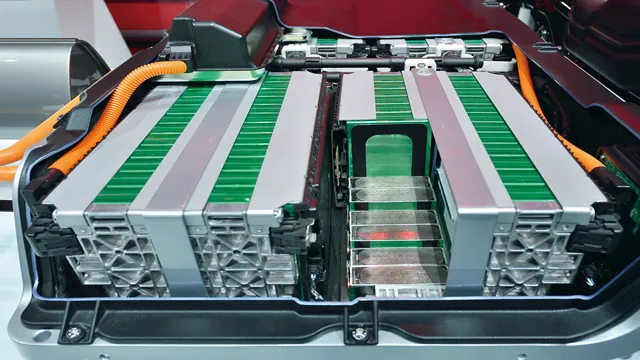

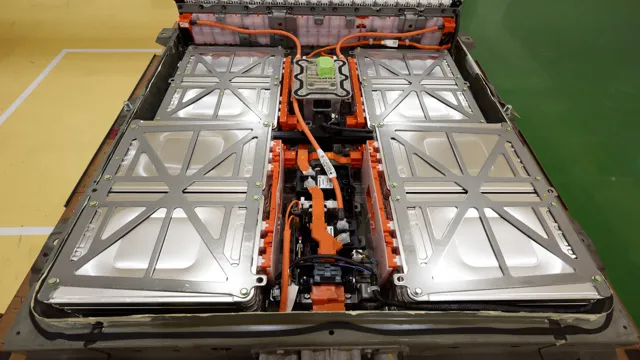

When it comes to battery containers in electric cars, aluminum is often the material of choice due to its unique properties. One major advantage of aluminum is its light weight, which can help reduce the overall weight of the vehicle and improve its energy efficiency. Additionally, aluminum is highly resistant to corrosion, so it can protect the sensitive battery components inside the container.

Aluminum also has excellent thermal conductivity, making it ideal for dissipating heat generated by the battery during operation. Compared to other materials, such as steel or plastic, aluminum offers superior strength and durability, making it a reliable choice for battery containers in electric cars. Overall, aluminum is a versatile and reliable material that can help ensure the safety and efficiency of electric vehicles on the road.

Steel

Steel When it comes to choosing the right material for your next project, it’s important to consider all of your options. Aluminum is a popular choice due to its lightweight nature and durability, but it’s not always the best choice for every job. Other materials, such as steel, may be a better fit depending on the specific project requirements.

Steel is known for its strength and reliability, making it a great choice for projects that require heavy-duty support. Additionally, steel is often more cost-effective than other materials like aluminum, making it a great budget-friendly option. Of course, every project is unique, so it’s important to carefully consider your material options before making a final decision.

By weighing the pros and cons of each option, you can select the material that is best suited for your needs, whether it be aluminum, steel or another material altogether.

Copper

Copper When it comes to choosing materials for electrical wiring, aluminum often comes to mind as an alternative to copper. However, there are also other materials that can be used for electrical wiring such as silver, gold, and even iron. While these materials may have their own unique properties, copper remains the preferred material for electrical wiring due to its high conductivity, durability, and affordability.

Copper is also known for its resistance to corrosion and ability to withstand high temperatures, making it ideal for use in various electrical applications. Although aluminum wiring may be cheaper than copper, it is generally less durable and can be prone to overheating and corrosion over time. So in the long run, copper may actually be the more cost-effective option.

When it comes to choosing materials for electrical wiring, copper remains the gold standard.

Nickel

Nickel When it comes to materials used in industrial settings, aluminum is often praised for its light weight and durability. However, there are other metals out there that can hold their own against aluminum, such as nickel. While nickel may not be as lightweight as aluminum, it is incredibly resistant to corrosion and can withstand high temperatures.

This makes it a popular choice for industries that deal with harsh environments, such as chemical processing and aerospace. Plus, nickel is highly versatile and can be alloyed with other metals to enhance its properties. So, while aluminum may be the go-to choice for many applications, it’s worth considering the benefits that nickel can bring to the table.

Whether you’re looking for corrosion resistance, high-temperature resistance, or just a versatile metal that can be tailored to your specific needs, nickel is definitely worth some consideration.

Future Use of Aluminum in Electric Cars

As electric cars become more and more popular, the use of aluminum for battery containers is also on the rise. Aluminum is a great choice for battery containers due to its light weight, durability, and ability to dissipate heat, which is crucial for high-performance batteries. In addition, aluminum is highly recyclable, making it an eco-friendly choice for electric cars.

While other materials like steel and plastic have also been used for battery containers, the advantages of aluminum make it a top choice for the future of electric cars. With the growing demand for electric vehicles, manufacturers are looking for ways to reduce weight and increase performance, and aluminum is poised to play a significant role in achieving those goals. It’s exciting to imagine a future where we can drive lighter, more efficient electric cars thanks to the versatility of aluminum.

Efficiency and Range

As the shift towards electric cars continues, automakers are constantly searching for ways to improve efficiency and increase range. One solution is the increased use of aluminum in vehicle production. Aluminum is a lightweight material that can help reduce the weight of an electric car, which in turn improves efficiency and range.

With the Battery Electric Vehicle (BEV) market growing, lightweight components can make a significant difference in performance. In fact, according to the Aluminum Association, for every 10% reduction in vehicle weight, there can be a 7% reduction in energy consumption. This means that by implementing aluminum into the production process, more electric cars can be produced with longer ranges and lower energy consumption.

The future looks bright for the use of aluminum in electric cars as automakers continue to innovate and prioritize sustainability.

Sustainability

Aluminum is becoming increasingly important in the development of electric cars due to its lightness and strength. With electric cars, one of the main concerns is the weight of the vehicle, as heavier cars require more energy to move and therefore have a shorter range. Aluminum is one of the best metals to use in the production of electric vehicles, as it is lightweight, durable, and recyclable, making it an environmentally friendly option.

However, it can be more expensive than other materials such as steel. Despite this, the benefits of using aluminum in electric cars make it a worthwhile investment for sustainability. As demand for electric cars grows, the future use of aluminum in their production is set to increase, providing a more sustainable future for the automotive industry.

Conclusion

In conclusion, aluminum has proven to be a sparkling choice for battery containers in electric cars. Its lightweight yet durable nature allows for greater efficiency and range, while also being more environmentally friendly than traditional materials. Plus, with its sleek and modern look, aluminum gives your electric car the ultimate shine.

So why settle for anything less than the best? Choose aluminum for a brighter future on the road.”

FAQs

Why is aluminum used for battery containers in electric cars?

Aluminum is used for battery containers in electric cars because it is lightweight, durable, and highly conductive, which makes it ideal for heat dissipation and efficient cooling.

How does aluminum compare to other materials for battery containers in electric cars?

Aluminum is a better choice for battery containers in electric cars compared to other materials like steel or plastic because it is lighter, stronger, and more resistant to corrosion.

Can aluminum battery containers be recycled in electric cars?

Yes, aluminum battery containers can be easily recycled in electric cars, making them a sustainable and environmentally-friendly choice for manufacturers.

What are some advantages of using aluminum for battery containers in electric cars?

Some advantages of using aluminum for battery containers in electric cars include lighter weight, better energy efficiency, longer lifespan, faster charging times, and improved safety due to its high thermal conductivity.