Busting the Myth: Unveiling the Truth about Electric Car Batteries Efficiency in Production

Electric car batteries have revolutionized the automotive industry. With rising concerns over environmental hazards, having an eco-friendly mode of transportation has become increasingly essential. When it comes to electric cars, the battery is the powerhouse.

It is responsible for running the motor, and the longer the battery lasts, the more distance the car covers on a single charge. But, how do electric car batteries work, and what makes them different from regular batteries? In this blog, we will dive deep into the world of electric car batteries, explore how they function, and discover the various types of batteries used in electric cars.

Efficiency of Battery Production

Are electric car batteries efficient to build? The answer is a bit complex, as it depends on various factors such as the materials utilized, production processes, and energy sources. However, several studies show that battery production efficiency has significantly improved in recent years. For instance, some carmakers have successfully reduced battery production costs by 80% in a decade.

This is an impressive result considering that electric vehicle (EV) batteries are still among the most expensive components. The most common types of EV batteries are lithium-ion (Li-ion), which require materials like lithium, cobalt, and nickel, among others. Therefore, one critical aspect of battery efficiency is to reduce the amount of these finite materials and develop better recycling and reuse processes.

Moreover, another promising technology is solid-state batteries, which could significantly increase energy density and boost efficiency in production. Overall, even though there’s still room for improvement, electric car batteries have undoubtedly become more efficient to build in recent years.

Raw Materials

When it comes to the efficiency of battery production, raw materials play a crucial role. The sourcing and processing of materials such as lithium, cobalt, and nickel can greatly impact the sustainability and cost-effectiveness of battery manufacturing. In recent years, there has been a push for increased transparency and ethical sourcing in the battery supply chain, as concerns about environmental impact and labor practices have come to light.

Additionally, advancements in technology and processing methods have enabled more efficient and cost-effective ways of utilizing these raw materials. By optimizing the production process and sourcing responsible materials, battery manufacturers can enhance their efficiency and reduce their environmental impact, ultimately benefiting both their bottom line and the planet.

Manufacturing Process

When it comes to manufacturing batteries, efficiency is key. The process of producing batteries involves numerous steps, including mixing materials, coating electrodes, and assembling the finished product. Across each of these stages, there are opportunities to reduce waste and enhance productivity.

For example, manufacturers can utilize automation to speed up the process and reduce the need for manual labor. They can also implement quality control measures to catch any defects early on, preventing costly rework down the line. By streamlining their manufacturing processes and optimizing each step, battery manufacturers can not only boost their productivity but also improve the overall quality of their products.

As such, the importance of efficiency in battery production cannot be overstated. It is essential for manufacturers to continually evaluate their processes and look for ways to enhance efficiency.

Benefits of Electric Car Batteries

Are electric car batteries efficient to build? The short answer is yes. In fact, building electric car batteries is much more efficient than building traditional car engines. Electric car batteries have fewer parts, require less maintenance, and have a longer lifespan than traditional car engines.

Additionally, electric car batteries are more environmentally friendly than traditional car engines. They produce zero emissions, meaning they do not pollute the air, and they use renewable energy sources such as wind, solar, and hydro power. In terms of efficiency, electric car batteries are superior to traditional car engines in every way.

They are faster, quieter, and more reliable. So, if you’re considering switching to an electric car, you can rest assured that its battery will be highly efficient and environmentally friendly.

Reduced Emissions

Electric car batteries are revolutionizing the automobile industry by reducing the amount of harmful emissions released into the environment. These batteries are designed to store energy, making it possible to power a car without the need for gasoline. The benefits of electric car batteries cannot be overstated.

They not only reduce the carbon footprint of automobiles, but they also provide a more cost-effective and sustainable mode of transportation. With electric cars, drivers can save money on fuel and make a positive impact on the environment. As the world moves towards a greener future, electric cars are becoming more and more popular.

By choosing to drive an electric car, individuals can contribute to the reduction of greenhouse gas emissions and help combat climate change. So, if you want to be a part of the solution, consider getting behind the wheel of an electric car and join the fight against climate change.

Lower Operating Costs

One of the biggest benefits of electric car batteries is their ability to lower operating costs for drivers. With a traditional gas-powered vehicle, fuel expenses can add up quickly, especially if you have a long commute or frequently travel long distances. But with an electric car, the primary source of power comes from electricity, which is often cheaper than gasoline.

Additionally, electric vehicles require fewer maintenance and repair costs, since they have fewer parts and don’t rely on oil changes or other traditional combustion engine services. That means that over time, owners of electric cars can save thousands of dollars on fuel and upkeep expenses. Plus, with the increasing availability of public charging stations and various government incentives, it’s becoming easier and more affordable than ever to switch to an electric vehicle.

So if you’re looking to save money and reduce your carbon footprint, consider making the switch to an electric car today!

Sustainability

Sustainability Electric car batteries offer numerous benefits to the environment and consumers alike. Firstly, they significantly reduce carbon emissions, which is a major contributor to global warming. Electric cars have zero emissions, meaning they don’t produce any of the toxic fumes that traditional gas-powered cars do.

This helps reduce smog and pollution, leading to cleaner air and a healthier planet. Additionally, electric car batteries require less maintenance than traditional batteries. This means that they don’t need to be changed or charged as often, saving consumers time and money.

Furthermore, most electric car batteries are recyclable, reducing the amount of waste produced by traditional batteries. This is an important step in promoting sustainability and reducing reliance on nonrenewable resources. All in all, electric car batteries are a key component in building a more eco-friendly world.

Future of Electric Car Batteries

As electric cars continue to gain popularity, many people are questioning the efficiency of building the batteries that power them. While there are concerns about the environmental impact of manufacturing these batteries, there are also promising developments in the technology that suggest they will become more efficient. For example, newer batteries are being developed that are better able to store energy, which means that they will be able to power electric cars for longer periods of time.

Additionally, manufacturers are working to reduce the amount of raw materials required in the battery production process, which will help to reduce waste and minimize environmental damage. While there is still work to be done to make electric car batteries more sustainable, it is clear that the technology is moving in the right direction. So, are electric car batteries efficient to build? While there is room for improvement, the answer is a resounding yes.

Advancements in Technology

Electric car batteries have come a long way in recent years, but there is still room for improvement when it comes to their range, charging time, and overall lifespan. Many manufacturers are investing heavily in research and development to find the best ways to achieve these goals, and there are several exciting advancements on the horizon. One of the most promising technologies being developed is solid-state batteries, which use a solid electrolyte instead of a liquid one, making them safer, more efficient, and longer-lasting.

Another promising development is the use of silicon anodes, which can increase energy density by up to 20% compared to traditional graphite anodes. As these and other technologies continue to evolve and improve, we can expect to see electric cars become more affordable, have longer ranges, and charge faster than ever before, making them a more attractive option for consumers looking to reduce their carbon footprint and save money on fuel costs in the long run.

Increased Production

The future of electric car batteries looks promising with increased production rates and advancements in technology. Manufacturers are investing heavily to scale up production of high-capacity, long-lasting batteries that can power electric vehicles for longer distances. With demand for electric cars on the rise due to government incentives and increased environmental awareness, the market for electric car batteries is set to boom.

The key to meeting demand will be in increasing production and reducing costs through economies of scale. As production increases, the cost of electric car batteries is expected to decline, making electric vehicles more affordable for the average consumer. This will ultimately fuel the transition to a sustainable, low-carbon transportation system.

So, buckle up and get ready for the ride as we enter the era of electric cars powered by advanced, high-capacity batteries.

Conclusion

In conclusion, the efficiency of building electric car batteries is a complex issue. While the materials used in the batteries are often environmentally friendly, the manufacturing process can be energy-intensive. Additionally, the disposal or recycling of batteries at the end of their lifespan presents its own set of challenges.

However, with advancements in technology and increased emphasis on sustainable practices, the future of electric car batteries looks promising. Let’s charge ahead towards a greener, electric future!”

FAQs

How do electric car batteries compare to traditional car batteries in terms of efficiency?

Electric car batteries are generally more efficient to build than traditional car batteries because they are designed to perform better and last longer over time. Additionally, electric car batteries require fewer raw materials to manufacture, reducing the environmental impact of their production.

Are there any drawbacks to using electric car batteries?

While electric car batteries are generally more efficient and environmentally friendly than traditional car batteries, they do have some drawbacks. These include a higher upfront cost to purchase and install, as well as limited range compared to a traditional gas-powered vehicle.

How long do electric car batteries typically last before needing to be replaced?

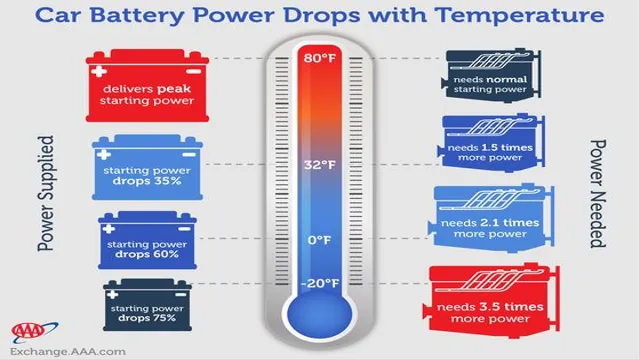

The lifespan of an electric car battery can vary depending on a number of factors, such as the quality of the battery, the climate in which it is used, and the driving habits of the vehicle owner. However, most modern electric car batteries are designed to last for at least 8-10 years before needing to be replaced.

Can electric car batteries be recycled or reused after they are no longer functional?

Yes, electric car batteries can be recycled or reused after they are no longer functional. This is an important consideration given the increasing demand for electric vehicles and the need to reduce waste and resource consumption in the manufacturing process. Many manufacturers now have programs in place to collect and recycle old electric car batteries.