Decoding the Myth: Are Electric Car Batteries Really Made from Fossil Fuels?

Are electric car batteries really as environmentally friendly as we think? As the world steadily moves towards greener alternatives to fossil fuels, the demand for electric cars has skyrocketed. With their silent engines and zero emissions, electric vehicles seem like the perfect solution to our pressing climate crisis. However, it’s time to take a closer look at the batteries that power them.

After all, where do these batteries come from? Are they truly free from the same fossil fuels they’re meant to replace? Many are now starting to ask, do electric car batteries have fossil fuel origins? In this blog, we’ll dive deep into the matter and uncover all the facts.

What are Electric Car Batteries?

One common question that people have about electric car batteries is whether they are made from fossil fuels. The answer is no. While it is true that fossil fuels are often used to generate the electricity that powers electric cars, the batteries themselves are typically made from rechargeable lithium-ion cells.

These cells are made up of a variety of different materials, including lithium, cobalt, and nickel. While mining these materials can have negative environmental impacts, companies are always looking for ways to reduce their environmental footprint and make their batteries more sustainable. Additionally, as the demand for electric cars continues to grow, many researchers are looking for new types of batteries that are even more environmentally friendly, such as solid-state batteries.

So while electric cars may not be perfect from an environmental standpoint, they are certainly a step in the right direction when it comes to reducing our reliance on fossil fuels.

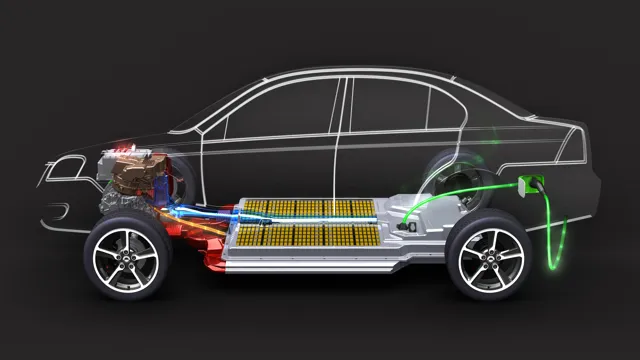

Composition and Functionality

Electric car batteries are the powerhouses that propel the vehicle forward. These batteries are a composition of multiple lithium-ion cells, connected together in a series, to provide the necessary voltage to produce an electric charge that powers up the car’s motor. The cells are organized into modules, which are then categorized into packs that can store a significant amount of energy.

These batteries can last for years, depending on their usage, and can have a lifespan of up to 10 years, giving electric cars a longer life cycle than their gasoline-powered counterparts. The most outstanding feature of these batteries is that they can charge both through regenerative braking, which means when the car brakes, the energy is recaptured and stored in the battery, and it can also charge through external charging. The batteries provide an impressive range of 200 to 300 miles, and with the advancement in technology, manufacturers aim to increase this range to reduce range anxiety among electric car owners.

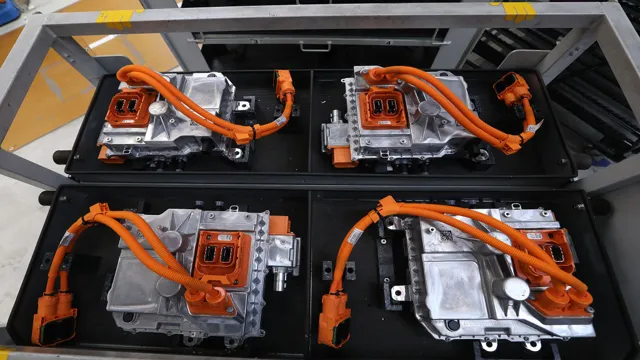

Types of Electric Car Batteries

Electric car batteries are the heart of any electric vehicle, as they are responsible for powering the car’s electric motor. There are various types of electric car batteries, but the most common are lithium-ion batteries. These batteries are known for their high energy density, which means they can store more energy in a smaller space, allowing electric cars to travel longer distances on a single charge.

Another type of battery that is gaining popularity is solid-state batteries, which are still undergoing development but have benefits such as being safer and having a longer lifespan compared to lithium-ion batteries. Other types of electric car batteries include nickel-metal hydride (NiMH) and lead-acid batteries, which are being phased out due to their lower range and environmental impact. When it comes to choosing the right electric car batteries, it depends on factors such as the car’s range, weight, cost, and environmental impact.

As technology continues to advance, we can expect to see even more advanced types of electric car batteries that will push the boundaries of automotive efficiency and sustainability.

Sourcing of Battery Components

Many people wonder whether electric car batteries are made from fossil fuels. The answer is no; the battery’s components are not directly made from fossil fuels. However, some of the materials in the batteries are derived from natural resources that are obtained through mining processes that rely on fossil fuels for transportation and energy.

For example, the production of the lithium required for these batteries consumes a lot of energy, and fossil fuels are usually the primary source of this energy. Additionally, the manufacturing process of the batteries requires a significant amount of energy, which can come from carbon-intensive sources like fossil fuels. The sourcing of battery components for electric cars is, therefore, complex.

While the batteries themselves are not made from fossil fuels, there is an indirect reliance on these fuels during their production. However, the good news is that advancements in renewable energy technology are making it more possible to produce electric cars and their batteries in a more sustainable way.

Origin of Lithium

The sourcing of lithium is becoming increasingly important as electric vehicles and renewable energy storage systems become more prevalent. Lithium is primarily obtained from salt flats in South America, particularly in countries such as Chile and Argentina. However, the production of lithium has been criticized for its environmental impact, as it requires large amounts of water and can lead to water scarcity and pollution.

As demand for lithium continues to rise, there is a need for more sustainable sourcing methods. Some companies are exploring new technologies, such as using geothermal energy to extract lithium, or recycling existing lithium-ion batteries to reduce the need for new production. It is vital to find sustainable and ethical sourcing methods to ensure the longevity and environmental impact of the lithium-ion battery industry.

Extraction and Processing of Metals

Sourcing of Battery Components When it comes to sourcing the components needed to produce batteries, it’s essential to consider the environmental and ethical impact of the extraction and processing of metals. Metals such as cobalt, lithium, and nickel are the primary materials used in battery production, and their extraction can have adverse effects on both the environment and local communities. For example, cobalt mining has been linked to child labor and unsafe working conditions.

Thus, it’s crucial for manufacturers to find responsible sources of these materials and ensure they are not contributing to these issues. One potential solution is to use recycled metals, reducing the need for extraction and processing from new sources. This approach not only benefits the environment but also supports circular economy practices.

Therefore, it’s imperative that manufacturers prioritize sustainability and ethical considerations when sourcing their battery components to minimize their negative impact.

Environmental Impact

When it comes to the environmental impact of batteries, the sourcing of their components is a crucial factor to consider. Many of the materials used in the production of batteries, such as lithium, cobalt, and nickel, are mined from the earth, often in countries with lax environmental regulations. This can lead to deforestation, habitat destruction, and pollution of air and waterways.

Additionally, the production of these materials requires a significant amount of energy and emits greenhouse gases, contributing to climate change. To address these issues, some companies are working to source materials more sustainably, through initiatives such as ethical mineral sourcing programs. By supporting these efforts and choosing products made with environmentally responsible materials, we can help reduce the negative impact of batteries on our planet.

Carbon Footprint of EV Batteries

Many people wonder whether electric car batteries are made from fossil fuels, which can contribute to the carbon footprint of the vehicles. While there are some components in batteries that are derived from petroleum, the majority of the materials used are not fossil fuel-based. In fact, many EV batteries are made using materials that are derived from more sustainable sources.

For example, the cathodes in lithium-ion batteries typically contain cobalt, which is often sourced from mines in the Democratic Republic of Congo. However, some companies are exploring alternatives to cobalt, such as nickel or manganese, which could help reduce the environmental impact of battery production. Additionally, as more renewable energy is used to power the factories that produce EV batteries, the overall carbon footprint of these vehicles will continue to decrease.

So, while there are still some challenges to be addressed when it comes to making EV batteries more sustainable, the industry is making progress towards a more environmentally friendly future.

Life Cycle Analysis

When it comes to electric vehicles (EVs), the topic of their environmental impact often centers on their batteries. It’s important to assess the carbon footprint of EV batteries to understand their life cycle impact. A life cycle analysis (LCA) includes every stage of production, operation, and disposal.

The carbon footprint of an EV battery is primarily determined by the electricity used during its production, the materials extracted to make it, and the emissions generated from the disposal process. However, critics argue that LCAs don’t necessarily account for the full picture and may fail to recognize the benefits of EVs relative to traditional Internal Combustion Engine (ICE) vehicles. Despite this, the EV industry is actively working to reduce the carbon footprint of batteries through more efficient manufacturing processes, sustainable sourcing of materials, and recycling initiatives.

Comparison with ICE Vehicles

When it comes to comparing electric vehicles (EVs) and internal combustion engine (ICE) vehicles, one of the most significant factors to consider is their carbon footprint. Many people are concerned about the environmental impact of the batteries used in EVs, and whether they create more pollution than traditional vehicles. However, research has shown that EV batteries have a significantly lower carbon footprint than ICE vehicles over their lifetime.

In fact, even when taking into account the manufacturing and disposal of EV batteries, they still produce fewer greenhouse gas emissions than ICE vehicles. This is because EVs are more energy-efficient and have zero tailpipe emissions, meaning they do not release harmful pollutants into the air. Overall, choosing an EV can help reduce your carbon footprint and contribute towards a more sustainable future.

Conclusion

As it turns out, the answer to whether electric car batteries are made from fossil fuels is not a straightforward one. While the production and manufacturing of the batteries may rely on some fossil fuel inputs, the overall environmental impact of electric vehicles is still lower compared to traditional gasoline-powered cars. So while we may not be completely able to cut the cord from fossil fuels just yet, the shift towards electric transportation still offers a promising and important step towards a cleaner, greener future.

“

FAQs

What materials are used to make electric car batteries?

Electric car batteries typically contain lithium-ion, nickel-metal hydride, or lead-acid, among other materials. However, these materials are not sourced directly from fossil fuels.

Do electric car batteries require fossil fuels to be manufactured?

While the materials used in electric car batteries do not come from fossil fuels directly, the manufacturing process itself does consume energy mostly from traditional power sources such as coal and natural gas.

Are there any alternatives to using fossil fuels in the production of electric car batteries?

Yes, manufacturers are exploring different methods of producing and sourcing materials for electric car batteries, such as using recycled materials and exploring alternative battery chemistries.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. In fact, recycling helps to reduce the need to mine new materials and can improve the sustainability of the manufacturing process.