Fossil Fuels in Electric Car Batteries: Debunking Myths and Uncovering the Truth

Fossil fuels and electric car batteries are two topics that seem to be at odds with one another. On one hand, fossil fuels are the traditional source of energy for vehicles, while electric car batteries offer a more sustainable alternative. However, there is more to the story than just the surface level contrasts.

In fact, the relationship between fossil fuels and electric car batteries is more complex than meets the eye. In this blog, we will examine how these two topics are intertwined, and what it means for the future of transportation. So, buckle up and get ready to explore the nuances of fossil fuels and electric car batteries!

Understanding the battery manufacturing process

Many people wonder if fossil fuels are used to make electric car batteries. While it is true that the production process of batteries involves energy and resources, including some non-renewable resources, the use of fossil fuels isn’t necessarily required. That being said, the majority of battery production currently relies on electricity derived from non-renewable sources such as coal and natural gas.

However, there is an increasing push towards using renewable energy sources in battery production, and many companies are already working towards this goal. It’s important to note that while electric cars are indeed more environmentally friendly than their gasoline counterparts in terms of emissions, we still have a long way to go to make battery production and disposal as sustainable as possible. So, while electric car batteries might not require the direct use of fossil fuels, there are still environmental impacts to consider when it comes to their production.

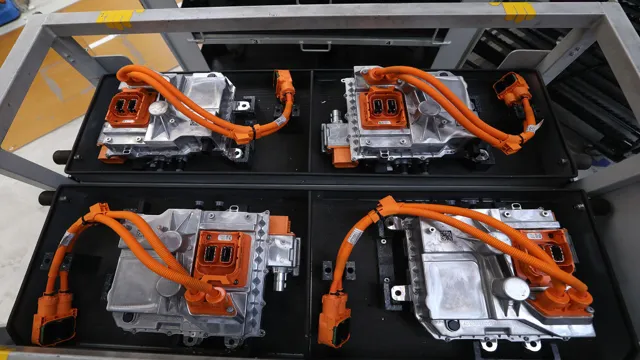

Determining the components of the electric car battery

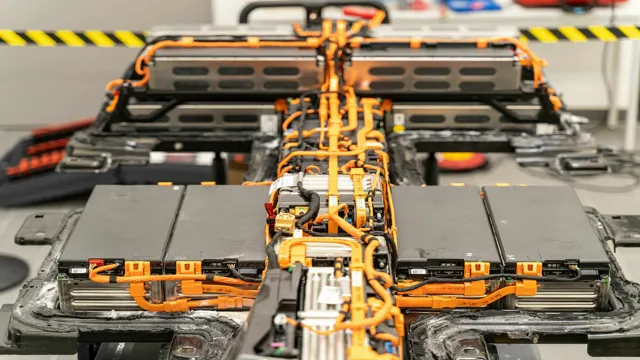

When it comes to electric cars, the battery is one of the most critical components. Understanding the battery manufacturing process can help you determine the components of an electric car battery. Batteries for electric cars are typically made up of several smaller cells daisy-chained together, and each cell includes a cathode, an anode, a separator, and an electrolyte.

The cathode and anode are made from lithium and other metals, and the separator is typically made from a thin polymer. The electrolyte is a liquid or gel that conducts ions between the cathode and anode. These materials are carefully chosen and coated to ensure the highest performance and longevity of the battery.

The manufacturing process involves several steps, including the mixing and coating of materials on a thin metal sheet, the assembly of cells, and the testing of the final product for quality control. By understanding the battery manufacturing process, you can appreciate the complexity and precision that goes into creating the key component of an electric car.

Overview of fossil fuels

Fossil fuels have been the primary source of energy for the world for centuries. These fuels, including coal, oil, and gas, are formed from the remains of ancient plants and animals that were buried millions of years ago. They are non-renewable sources of energy, which means that their supply is limited and will eventually be depleted.

However, they remain vital for our daily lives, powering everything from transportation to electricity generation. On the other hand, the battery manufacturing process is an essential aspect of the development of sustainable energy production. Batteries store energy for later use, making them a crucial element in renewable energy sources like solar and wind.

The manufacturing process includes many stages, including material selection, electrode design, cell assembly, and battery testing. The ultimate goal is to create a battery that is efficient, reliable, and cost-effective. As the world moves towards a more sustainable future, understanding the battery manufacturing process is critical so that we can continue to rely on fossil fuels less and less.

Examining the link between fossil fuels and battery production

One question that frequently arises in discussions about electric cars is whether or not fossil fuels are used in the production of batteries. The short answer is yes, but the extent to which they are used varies. The manufacturing of lithium-ion batteries, which are commonly used in electric cars, requires minerals such as lithium, cobalt, and nickel.

These minerals are often mined using fossil fuel-powered equipment. Additionally, the transportation of these minerals from the mine to the factory where the batteries are produced typically involves the use of trucks or other vehicles powered by fossil fuels. However, it’s worth noting that some battery manufacturers are making efforts to reduce their carbon footprint by sourcing minerals sustainably and using renewable energy in their manufacturing processes.

So, while it’s true that some fossil fuels are involved in battery production, the industry is taking steps towards sustainability.

Analysis of the mining process for battery minerals

The mining process for battery minerals is often criticized for its link to fossil fuels and the negative impact on the environment. In the search for minerals such as lithium, cobalt, and nickel, large amounts of energy and water are required, which leads to increased carbon emissions and water scarcity. This is a major challenge for the global battery industry, which is working hard to reduce its reliance on fossil fuels and find more sustainable alternatives.

A possible solution is to implement renewable energy sources such as solar and wind power in the mining process. Also, the recycling of batteries is gaining more ground, which leads to significant reductions in mining and greenhouse gas emissions. Nevertheless, the mining of battery minerals is still a complex issue that requires extensive research and thoughtful consideration to balance the demand for batteries with environmental sustainability.

Usage of fossil fuels in the manufacturing plants

As the world shifts towards renewable energy sources, the use of fossil fuels remains a significant factor in battery production. The manufacturing plants for batteries require huge amounts of energy, and this energy often comes from non-renewable resources like coal and natural gas. This heavy reliance on fossil fuels poses a significant challenge to achieving sustainability in battery production.

However, there are steps being taken to address this issue. For instance, some manufacturers are investing in renewable energy sources like solar and wind to power their plants. Additionally, there is a growing trend towards the use of closed-loop recycling in battery production, reducing the need for newly mined resources.

By addressing the link between fossil fuels and battery production, we can create a more sustainable future for the industry.

Alternative manufacturing methods being explored

As the world moves towards more sustainable energy sources, alternative manufacturing methods for batteries are being explored. One such method is using renewable energy sources, such as wind and solar, to power the manufacturing process. However, a lesser-known aspect of battery production is the link to fossil fuels.

The mining and processing of metals used in batteries, such as lithium and cobalt, often rely on fossil fuels for energy. In addition, transporting the materials and components to and from manufacturing sites also adds to the carbon footprint. To truly achieve a green energy transition, it is important to consider the entire supply chain of battery production and find innovative solutions to reduce its dependence on fossil fuels.

One potential solution is developing more efficient and eco-friendly extraction methods for raw materials. By doing so, we can take a step closer towards a cleaner and more sustainable future.

Sustainability in the electric car battery industry

One of the common concerns raised about electric cars is whether fossil fuels are used in the production of their batteries. It’s true that the manufacturing process of electric car batteries involves some fossil fuels. However, the level of fossil fuel usage is relatively low when compared to the entire lifecycle of the battery.

Additionally, there are efforts being made to reduce and eventually eliminate the use of fossil fuels in battery production. Electric car manufacturers are investing in sustainable technologies such as renewable energy sources and recycling programs to create more environmentally-friendly batteries. It’s important to note that the switch to electric cars isn’t just about reducing emissions but also about creating a sustainable future where sustainable resources are used and waste is minimized.

While the electric car battery industry has room for improvement, progress is being made to ensure that fossil fuel usage is minimized and eco-friendliness is maximized.

The push for renewable energy sources in battery production

The push for renewable energy sources in battery production is driven by the need for sustainability in the electric car battery industry. As the demand for electric vehicles increases, so does the demand for lithium-ion batteries, and the production of these batteries often leads to carbon emissions and environmental degradation. To combat this, companies are looking towards renewable energy sources such as wind and solar power to power their battery manufacturing facilities.

By utilizing renewable energy sources, the carbon footprint of the battery production process is significantly reduced, and the overall sustainability of the manufacturing process is improved. This push towards sustainable practices in battery production is not only beneficial for the environment but also for the companies themselves, as consumers are becoming more environmentally conscious and are looking to support companies that prioritize sustainability. Ultimately, the shift towards renewable energy sources in battery production is a necessary step towards a greener future.

The rise of eco-friendly manufacturing practices

The electric car battery industry has made significant strides in implementing sustainable manufacturing practices. With the rise of eco-friendly technology, companies are increasingly turning to green alternatives to reduce their environmental footprint. For example, many electric car battery companies are utilizing recycled materials in their products, such as repurposed metal and plastic.

Furthermore, some manufacturers have adopted closed-loop manufacturing processes, which involve recycling waste materials back into the production cycle. These practices not only benefit the environment, but they also have financial benefits by reducing the cost of raw materials and waste disposal. Overall, sustainability is becoming an essential aspect of the electric car battery industry, and it is encouraging to see companies taking steps to protect our planet.

Moving towards a greener future

Many people wonder if fossil fuels are used to make electric car batteries. The answer is not simple. While electric cars are viewed as a cleaner alternative to petrol and diesel-powered cars, they still require energy and resources to produce.

The production process of electric cars includes the manufacturing of batteries, which are typically made using lithium-ion. Lithium is a rare metal that is found in the earth’s crust and typically extracted using a process that involves fossil fuels. However, fossil fuels are not the only method for extraction.

Alternative methods like hydro-electric power can also be used to extract lithium. Ultimately, it depends on the manufacturing process, location, and availability of resources. Although electric cars have a lower carbon footprint when driven than petrol and diesel cars, the production of electric cars still has room for improvement in terms of its environmental impact.

Conclusion

After conducting research, it is safe to say that using fossil fuels to create electric car batteries would be like building a beautiful mansion on a foundation of sand. While it may seem like a quick fix, the long-term implications and environmental impact would be devastating. Instead, we must continue to explore and invest in sustainable energy sources to power not only our electric vehicles but our world as a whole.

“

FAQs

What materials are used to make electric car batteries?

Electric car batteries are typically made from a combination of materials like lithium, nickel, cobalt, and manganese, as well as aluminum and copper for wiring and casing.

Do fossil fuels play a part in the manufacturing of electric car batteries?

Yes, fossil fuels are often used in the production processes of some materials used in electric car batteries, such as mining and transport of raw materials.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled to reclaim valuable materials like lithium and cobalt, reduce waste, and decrease environmental impact.

How long do electric car batteries last before needing replacement?

The lifespan of electric car batteries can vary, but most manufacturers offer warranties of 8+ years or 100,000+ miles. With proper maintenance and care, some batteries can last even longer.