The Shocking Truth Behind Where Batteries for Electric Cars Are Made

Electric cars are becoming increasingly popular, and for good reason. They are eco-friendly, sustainable, and produce zero emissions, making them the perfect choice for those looking to reduce their carbon footprint. However, one question that many people have is: where are electric car batteries made? The manufacturing process of electric car batteries is complex, involving various materials such as lithium, cobalt, and nickel.

These materials are sourced from different parts of the world, and the batteries themselves are typically assembled in specialized factories. In this blog post, we’ll explore the intricacies of electric car battery manufacturing, including where these batteries are made and the impact that this process can have on the environment. We’ll also take a closer look at the materials used to make these batteries and the role that they play in the overall sustainability of electric cars.

So, if you’ve ever wondered about the origins of electric car batteries and how they’re made, keep reading! We’ve got all the information you need to satisfy your curiosity and learn more about these innovative and eco-friendly vehicles.

Introduction

If you’re wondering where batteries for electric cars are made, the simple answer is that they are manufactured in battery factories. These factories typically produce lithium-ion batteries, which are the most common type of battery used in electric cars. Additionally, the materials used to make these batteries are sourced from all over the world.

For example, lithium is usually mined in countries like Chile, Argentina, and Australia, while cobalt comes from countries such as the Democratic Republic of Congo, Russia, and Australia. Once all of the necessary materials are collected, the battery cells are produced in battery factories, which can be found all around the globe. Some of the largest battery factories are located in China, which is a major player in the electric vehicle industry.

Other countries such as the United States and Germany also have large battery factories. These factories play a crucial role in enabling the growth of the electric car industry by producing reliable and efficient batteries for vehicles.

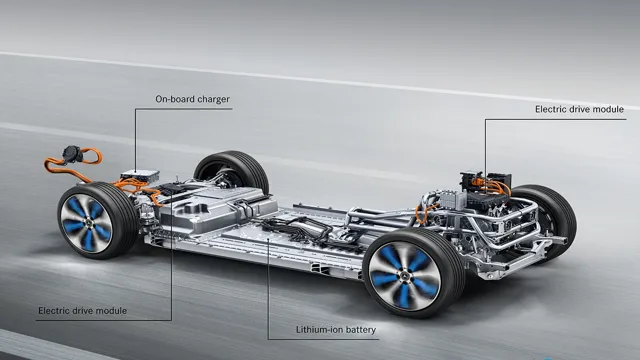

The Role of Batteries in Electric Cars

Electric cars are becoming increasingly popular due to their environmentally-friendly nature and cost-efficiency. However, the success of these vehicles heavily relies on the battery technology used to power them. Electric car batteries must possess high energy density and durability to provide sufficient power and long ranges.

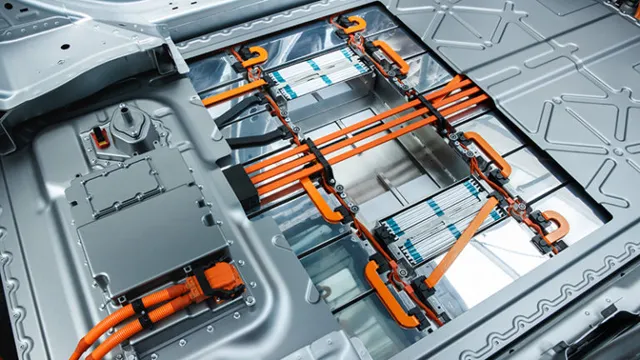

Lithium-ion batteries are currently the most commonly utilized battery type for electric vehicles, due to their high power to weight ratio and long cycle life. The construction of electric car batteries involves numerous components including electrodes, electrolytes, and separators. These components work in tandem to produce a steady flow of electricity, which powers the vehicle.

Although current battery technology has made significant strides in the past decade, there is still room for improvement, with research focused on developing batteries that are even more efficient, longer-lasting and economical. The role of batteries in electric cars is therefore paramount to ensuring the widespread adoption and success of electric vehicles.

Global Battery Production

If you’re curious about where batteries for electric cars are made, the answer is that there isn’t a single global hub for production. Instead, battery factories can be found all throughout the world, from Asia to Europe to the Americas. One reason for this is that different automakers have partnered with different battery suppliers, leading to a diffused market.

Additionally, some countries have invested more heavily in battery production infrastructure than others, which can impact where specific types of batteries are made. However, there are a few regions that have emerged as significant players in the global battery manufacturing market. For example, China is currently the largest producer of lithium-ion batteries, which are the most commonly used type of battery in electric cars.

Meanwhile, Europe is quickly becoming a key player in battery production, with major companies like Tesla and LG Chem investing in factories throughout the continent. Ultimately, the location of battery production is an ever-shifting landscape, with various factors coming into play to determine where batteries for electric cars will be made.

Top Battery Manufacturers

When it comes to battery production, there are a number of top manufacturers leading the way in the global market. These companies are responsible for producing some of the highest quality batteries available today, with a focus on efficiency, durability, and sustainability. Among the top battery manufacturers are companies like Panasonic, Tesla, LG Chem, Samsung SDI, and CATL.

Each of these companies brings a unique approach to battery production, with different strengths and specialties. For example, Panasonic is known for producing high-performance batteries with a long lifespan, while Tesla focuses on developing batteries that can power high-performance electric vehicles. Meanwhile, LG Chem is a leader in the production of lithium-ion batteries, and Samsung SDI is known for developing cutting-edge battery technologies.

Finally, CATL is a rising star in the battery industry, with a focus on developing sustainable technologies that minimize environmental impact. Overall, these top battery manufacturers are making a significant impact on the global battery market and driving innovation in the field.

Regional Battery Production

Global Battery Production With the rapid expansion of the electric vehicle industry, the demand for battery production has skyrocketed worldwide. Global battery production has increased significantly in the last few years, with Asia leading the way. China alone accounts for over 70% of global lithium-ion battery production, followed by South Korea and Japan.

However, several countries, including the United States and Europe, are looking to increase their regional battery production to support their domestic electric vehicle markets. The United States, for example, is investing in building domestic battery production capacity to reduce dependence on foreign battery manufacturers. Europe, on the other hand, has set a goal to become a global leader in green battery production, with several initiatives and funds in place to support the development and scaling of battery production in the region.

As global demand for electric vehicles continues to grow, increasing regional battery production is crucial to meeting this demand and establishing a sustainable future.

The Battery Supply Chain

One might be surprised to learn that the process of manufacturing batteries for electric cars is a complex and global affair. While certain components and materials may be sourced locally, the production and assembly of batteries typically involves a network of suppliers and manufacturers scattered across various countries. For instance, South Korea is a major hub for battery production, with companies like LG Chem and Samsung SDI leading the way in supplying batteries to automakers around the world.

Japan and China are also key players in the battery supply chain, with many Japanese automakers sourcing their batteries domestically and China investing heavily in battery technology as part of its goal to become a global leader in electric vehicles. Overall, the battery supply chain reflects the interconnectedness of the global economy and the importance of collaboration in creating sustainable technologies for a cleaner future.

Raw Materials for Batteries

The battery supply chain is an intricate web of raw materials and processes that need to be carefully managed in order to produce high-quality batteries. One of the primary raw materials used in batteries is lithium. Lithium can be found in the earth’s crust, but the process of extracting it can be complex and expensive.

Other materials used in batteries include cobalt, nickel, and graphite. Unfortunately, these materials can also be difficult and expensive to mine. As a result, the battery supply chain is subject to fluctuations in price and availability, which can impact the cost and reliability of batteries.

It’s important for suppliers and manufacturers to work together to develop sustainable and responsible supply chain practices that ensure the availability of these raw materials for years to come. By doing so, they can help to create a more stable and predictable battery supply chain that meets the growing demand for clean energy solutions.

Manufacturing Processes

The battery supply chain is a complex process that involves various stages from mining raw materials to producing finished batteries. It starts with extracting minerals like lithium, cobalt, and nickel from mining sites using heavy machinery and chemicals. These minerals are then transported to refineries where they are processed into metal compounds.

These compounds are further processed into metals that are sold to battery manufacturers. The battery manufacturers use these metals to produce different types of batteries such as lithium-ion, nickel-cadmium, and lead-acid, among others. The batteries are then sent to various industries such as the automotive, renewable energy, and consumer electronics industries.

The battery supply chain also involves recycling and disposal of used batteries to ensure sustainable and responsible practices. Overall, the battery supply chain is critical in meeting the growing demand for batteries as the world shifts towards green energy.

The Future of Battery Production

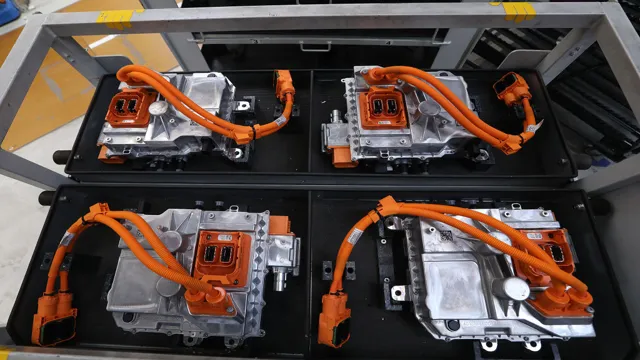

Batteries for electric cars are made in specialized factories that are capable of producing high-quality cells on a large scale. The future of battery production lies in innovations that increase the efficiency and sustainability of the manufacturing process. For instance, many companies are investing in automating production lines to reduce labor costs and decrease the risk of human error.

Additionally, there is a growing interest in developing new materials for battery components, such as cathodes and anodes, that can improve energy density and extend the lifespan of the batteries. With the increasing demand for electric vehicles worldwide, battery manufacturers are continually improving their operations to meet the needs of the emerging market. As battery technology continues to evolve, we can expect to see new breakthroughs that will make electric cars more accessible and affordable for consumers.

Emerging Battery Technologies

As technology continues to advance, so does the need for more efficient and powerful battery production. There are currently many emerging battery technologies that have the potential to revolutionize the way we store and use energy. One such technology is the solid-state battery.

Unlike traditional lithium-ion batteries that use a liquid electrolyte, solid-state batteries use a solid electrolyte, allowing for improved safety and energy density. Another emerging technology is the flow battery, which uses liquid electrolytes that can be replaced when they are depleted, making it a viable option for long-term energy storage. Additionally, researchers are exploring the use of different materials, such as sodium and magnesium, as potential alternatives to lithium in battery production.

These emerging battery technologies hold great promise for the future of energy storage and will likely play a significant role in powering our world for years to come.

The Impact of Electric Cars on Battery Production

The rise of electric cars has brought with it a surge in battery production. As more people make the shift to eco-friendly transportation, the demand for batteries is expected to grow exponentially. This presents an exciting opportunity for battery manufacturers, but also a challenge.

They must find a way to ramp up production without compromising on quality or safety. Fortunately, advancements in technology are making this possible. Many companies are now investing in automated production techniques that can increase output while minimizing errors.

Additionally, battery manufacturers are constantly researching and developing new materials that can improve the performance and lifespan of their products. As a result, the future of battery production looks bright, and we can expect to see even more efficient and reliable batteries in the years to come.

Conclusion

In conclusion, batteries for electric cars are made in specialized factories that are powered by renewable energy sources. These factories require highly skilled engineers and technicians who are responsible for creating some of the most innovative and advanced batteries in the world. So, next time you enjoy a smooth, quiet ride in your electric car, take a moment to appreciate the fact that its power source was made with care, precision, and a commitment to sustainability.

“

FAQs

What materials are used to make batteries for electric cars?

Batteries for electric cars are typically made using materials such as lithium, nickel, cobalt, and manganese.

How are batteries for electric cars manufactured?

The manufacturing process for batteries used in electric cars involves several steps including electrode preparation, cell assembly, and battery pack assembly.

Why are lithium-ion batteries commonly used in electric cars?

Lithium-ion batteries are used in electric cars due to their high energy density, long cycle life, and low self-discharge rate.

Where are most batteries for electric cars manufactured?

While batteries for electric cars are manufactured in various locations around the world, a significant portion are produced in countries such as China, Japan, and South Korea.