Powering the Future: The Role of Mining in Producing Batteries for Electric Cars

Mining companies around the world are adopting electric vehicles (EVs) due to their cost-effectiveness and eco-friendliness. However, optimizing battery life for these EVs is a challenge that mine operators need to overcome. With the constant demand for mining operations to become more efficient, finding ways to ensure EVs can run for longer distances without recharging is essential to keep up the pace.

So, in this blog, we’ll discuss how mining companies can optimize battery life for their electric vehicles to operate efficiently in mining operations.

Mining EVs and Battery Usage

When it comes to electric vehicles (EVs), the batteries that power them are a vital component. However, what many people may not realize is that the production of these batteries involves mining and extracting rare metals and minerals. These materials, including cobalt, nickel, and lithium, are crucial in the manufacturing of the battery cells.

Mining for these materials can result in environmental damage and human rights issues in some countries. In addition, the process of mining and producing these batteries requires a significant amount of energy and resources. Despite these challenges, it is important to note that EVs ultimately have a lower carbon footprint than traditional gasoline-powered cars, and advancements in battery technology may lead to more sustainable production methods.

The demands of mining operations on EV batteries

As mining operations turn to electric vehicles (EVs) for a more sustainable form of transportation, the demands placed on the batteries powering these vehicles are increasing. Mining operations often require EVs to operate in harsh, remote environments, with long distances to travel and heavy loads to carry. These conditions put pressure on the battery’s charging and discharging capabilities, as well as its overall durability and lifespan.

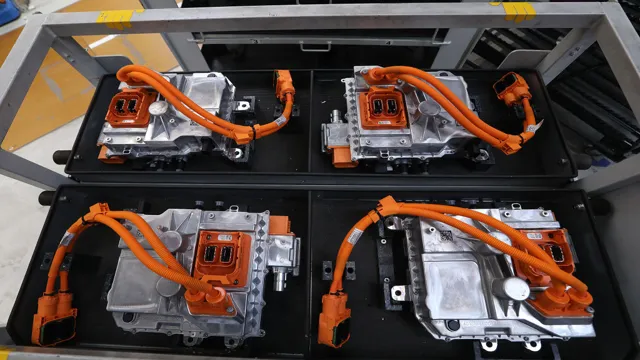

Furthermore, the batteries used in mining EVs must be designed to handle the unique demands of their environment, including exposure to extreme temperatures and vibrations. To meet these needs, battery manufacturers are developing specialized batteries that can withstand the rigors of mining operations. These batteries are designed with improved thermal management, higher energy density, and faster charging capabilities, ensuring that mining EVs can continue to operate efficiently and safely in demanding environments.

Battery performance in extreme mining conditions

Mining EVs and Battery Usage Mining vehicles are exposed to extreme conditions that require high battery performance. These conditions include high altitudes, rugged terrains, and high temperatures. Therefore, miners require batteries that can withstand these harsh conditions and have a long lifespan.

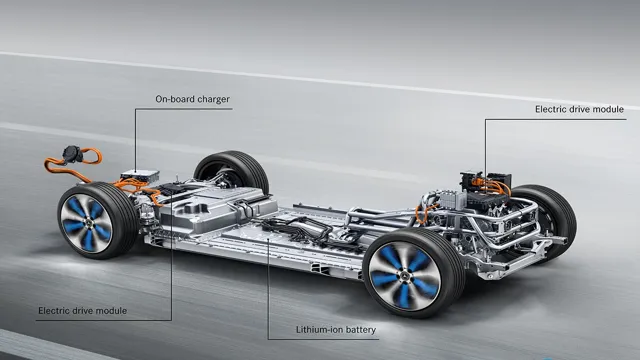

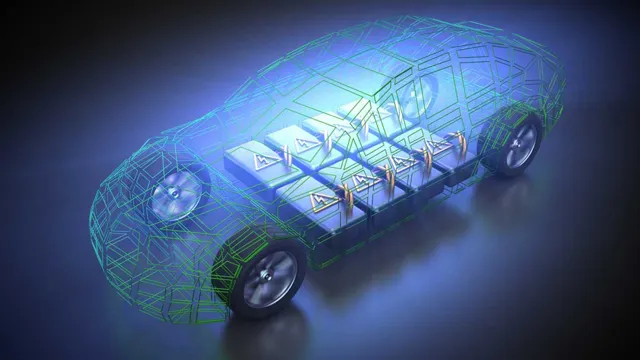

Lithium-ion batteries are the most commonly used batteries in mining EVs because they have high energy-density, long lifespan, and low maintenance requirements. These batteries are also environmentally friendly and can be recycled. However, to ensure optimal performance, proper battery management is necessary.

This includes regular charging, monitoring, and maintenance to avoid overcharging or discharging, which can cause irreversible damage to the batteries. Therefore, mining companies need to invest in advanced battery management systems to enhance battery performance and prolong lifespan. In summary, optimal battery performance is vital in mining operations, and the use of lithium-ion batteries paired with advanced battery management systems can significantly improve battery efficiency and lifespan.

Types of Batteries for Mining EVs

When it comes to powering electric vehicles used in mining operations, there are generally two types of batteries to choose from: lithium-ion and nickel-metal hydride. Lithium-ion batteries are lighter and more compact, making them a popular choice for EVs in general, but they can also be more expensive and have a shorter lifespan. Nickel-metal hydride batteries, on the other hand, are heavier and bulkier but can offer a longer lifespan and better performance in extreme temperatures.

Ultimately, the choice between these two types of batteries will depend on a number of factors, including the specific needs of the mining operation, budget constraints, and the anticipated environmental conditions. Some mining companies are also experimenting with other battery chemistries, such as solid-state batteries, that may offer even better performance and longer lifespans in the future.

Comparing lithium-ion and solid-state batteries

When it comes to batteries for mining EVs, there are two main types to consider: lithium-ion and solid-state. Both offer advantages and disadvantages, and it’s important to understand these differences to make an informed decision. Lithium-ion batteries are currently the most commonly used type for EVs due to their high energy density and relatively low cost.

However, solid-state batteries are rapidly gaining popularity due to their potential for even higher energy densities, increased safety, and longer lifespans. Solid-state batteries also have the advantage of being able to charge faster and handle higher temperatures than lithium-ion batteries. Ultimately, the choice between lithium-ion and solid-state batteries will depend on the specific needs of the mining operation, as well as factors such as cost and availability.

Benefits and limitations of each battery type

When it comes to powering mining EVs, there are several types of batteries to choose from, each with its own benefits and limitations. Lead-acid batteries are the oldest and most widely used, thanks to their low cost and high reliability. However, they are heavy, have a limited lifespan, and require regular maintenance.

Lithium-ion batteries offer a higher energy density, longer lifespan, and are less prone to self-discharge, making them ideal for high-performance EVs. However, they are more expensive, can be sensitive to temperature changes and require sophisticated battery management systems. Nickel-cadmium batteries are also a popular choice for mining EVs due to their high power density, durability, and fast charge times.

However, they are toxic, difficult to dispose of, and have a limited capacity. Each battery type has its pros and cons, so it’s important to consider the specific needs of your mining operation to determine the best fit.

Other emerging battery technologies to watch

As mining companies continue to shift towards electrification, a variety of battery types are emerging to meet their specific needs. One promising option is the lithium-sulfur battery, which boasts a much higher energy density than the commonly-used lithium-ion battery. However, there are still hurdles to overcome, such as issues with stability and lifespan.

Another option is the solid-state battery, which replaces the liquid electrolyte in a lithium-ion battery with a solid material. This offers potential advantages in terms of safety and energy density, but commercialization is still in its early stages. Finally, there are flow batteries, which use a liquid electrolyte stored in external tanks and pumped through the battery as needed.

These batteries can be scaled up easily and have a long lifespan, but are currently limited by low energy density and high cost. As the mining industry continues its transition to electric vehicles, it will be fascinating to see which of these emerging battery technologies proves to be the most effective for their unique needs.

Factors to Consider in Choosing Mining EV Batteries

When it comes to selecting batteries for electric cars that will be used in mining applications, there are several important factors to consider. One of the most significant factors is the battery’s energy density. Since mining vehicles typically require a lot of power, higher energy density batteries are essential to ensure a longer range and better performance.

Additionally, battery durability and reliability should also be taken into account since mining operations can be quite harsh and demanding on equipment. Another important consideration is the battery’s charging speed, particularly in instances where downtime can be very costly. Ultimately, the batteries chosen for mining electric vehicles should be robust enough to withstand the rigors of mining operations while providing sufficient power and range to meet the requirements.

Mining application and vehicle type

When it comes to choosing the right batteries for your mining EV, several factors need to be considered to ensure you make the best decision. The first and foremost element is the type of application and vehicle. Different mining applications and vehicle types require different battery specs due to differing power requirements.

For instance, a hauling truck will require a more robust battery than a smaller vehicle that mining technicians use to navigate terrain. Additionally, the temperatures and pressure conditions in underground mining sites tend to be harsher, so you need to choose batteries that can withstand such conditions. Another critical factor to consider is battery lifespan and charging time.

Downtime can be an expensive inconvenience, so it’s essential to select EV batteries with long lifespans and faster charging times to maximize operational efficiency. Ultimately, working with a reputable battery supplier and exploring the full range of options available in the market can help you make an informed decision that meets the specific needs of your mining operations.

Performance requirements and battery capacity

When choosing mining EV batteries, it’s essential to consider several factors. One of the most important factors is the battery capacity and its performance requirements. As mining equipment requires a lot of power, the battery capacity must be high enough to handle the workload.

The battery’s performance requirements refer to its ability to maintain a stable voltage and current output over time. This ensures that the equipment operates efficiently and at optimal levels. Additionally, mining vehicles often require heavy payloads, meaning the batteries used must have a high energy density to provide enough energy to support the weight.

Moreover, the battery’s reliability is also crucial. Mining operations are often conducted in harsh environments, and the last thing you want is for your battery to fail when you need it the most. That’s why it’s essential to choose batteries that are designed for tough conditions.

Manufacturers must test their batteries under these conditions before they are considered for use in mining vehicles. In summary, when choosing mining EV batteries, the battery capacity and performance requirements should be carefully considered. Other crucial factors include reliability and the ability to handle tough conditions.

By taking into account these factors, mining companies can ensure they are getting the best batteries for their operations, which translates to increased efficiency and productivity.

Sustainable Practices in Battery Manufacturing and Disposal

When it comes to creating batteries for electric cars, mining plays a significant role in the process. However, sustainable practices are crucial for both the manufacturing and disposal of batteries. Mining for key materials like lithium, nickel, and cobalt can have negative environmental impacts, but there are efforts to reduce these impacts through responsible sourcing and recycling.

Similarly, when it comes to disposing of batteries, proper recycling processes need to be in place to prevent harmful chemicals and materials from entering the environment. It’s essential to consider the entire lifecycle of a battery, from mining to disposal, when striving for a more sustainable future. By incorporating efficient and environmentally-conscious practices, we can create electric car batteries while minimizing negative impacts on our planet.

Conclusion

In conclusion, batteries for electric cars are the powerhouses behind the green revolution in the auto industry. However, the mining that goes into these batteries presents both challenges and opportunities for sustainability. The solution lies in innovative and responsible mining practices that not only prioritize the planet but also support the livelihoods of those involved.

So let’s charge ahead, with a fully charged battery and a dedicated commitment to environmental stewardship!”

FAQs

What are the primary minerals mined for batteries used in electric cars?

The primary minerals mined for batteries used in electric cars are lithium, cobalt, and nickel.

How much of the world’s cobalt production is used in electric car batteries?

As of 2021, approximately 70% of the world’s cobalt production is used in electric car batteries.

What are the environmental impacts of mining for battery minerals?

The mining of battery minerals can have negative environmental impacts such as soil erosion and water pollution.

How does the demand for electric car batteries affect the mining industry?

The increasing demand for electric car batteries has led to an increase in demand for battery minerals, driving growth in the mining industry.