Brightening Up The Roads of India: Exploring the Evolution of Batteries Used in Electric Cars!

India’s commitment to reducing its carbon footprint has led to a growing interest in electric cars. However, the success of electric vehicles depends heavily on the performance of their batteries. In recent years, India has been ramping up its domestic production of electric car batteries, with major players such as Tata Chemicals, Exide Industries, and Amara Raja Batteries stepping up to the plate.

But what exactly sets these batteries apart from their counterparts, and are they well-suited for India’s unique conditions? Join us as we explore the current state of electric car batteries in India and what we can expect in the future.

Overview of Electric Car Market

When it comes to the batteries used in electric cars in India, there has been a significant shift towards lithium-ion batteries. These batteries have become the most popular choice for electric vehicles due to their high energy density, longer lifespan, and faster charging capabilities. Additionally, many manufacturers have started to produce these batteries locally, reducing the cost of production and enabling more affordable electric vehicle options.

Government incentives and regulations have also played a significant role in promoting the adoption of electric vehicles in India. The Indian government has set a target of 30% electric vehicle penetration by 2030 and has implemented policies such as reduced goods and services tax, subsidies and exemptions to boost the growth of this market. However, there are still challenges to overcome, such as limited charging infrastructure, high initial costs, and concerns over the environmental impact of battery disposal.

Despite this, the electric car market is expected to continue to grow rapidly, powered by advances in battery technology and government support.

Statistics on Electric Car Adoption

The electric car market has been growing steadily in recent years, with more and more consumers opting for a greener alternative to traditional gasoline-powered vehicles. According to statistics, the global electric car market is expected to reach $8081 billion by 2027, growing at a CAGR of 2

6% from 2020 to 202 As the world becomes more environmentally conscious, the demand for electric vehicles is expected to increase as well. Governments around the world are also providing support, offering incentives and subsidies to encourage the adoption of electric cars.

In fact, Norway leads the way in electric car adoption with over 70% of new cars sold in 2020 being electric. Other countries like China and the UK are also making significant strides in reducing their carbon footprint by promoting the use of electric cars. As charging infrastructure improves and battery technology becomes more advanced, the future looks bright for electric car adoption.

Types of Electric Cars Available in India

The electric car market in India is slowly gaining momentum as more consumers become environmentally conscious and embrace sustainable living. Electric cars are of various types, ranging from hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) to battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs). HEVs and PHEVs are relatively new to the Indian market, and the most popular electric cars in the country are BEVs.

BEVs run entirely on electricity and have a limited range of around 150 to 250 km on a single charge. Whereas FCEVs use hydrogen as their primary fuel source, and they emit only water vapor. Nevertheless, FCEVs haven’t made it to the Indian market yet.

India’s government has set a goal of having 30% electric vehicles on the road by 2030, and as the country’s charging infrastructure continues to develop, more consumers are likely to switch to electric cars.

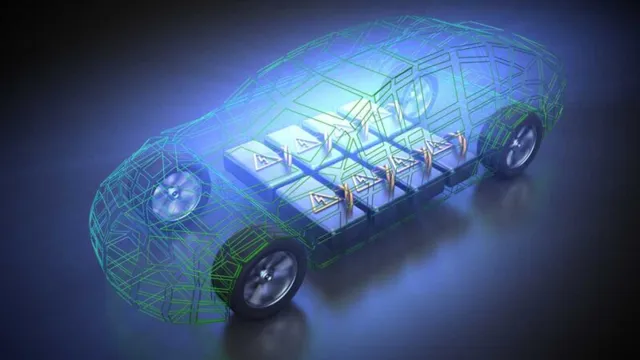

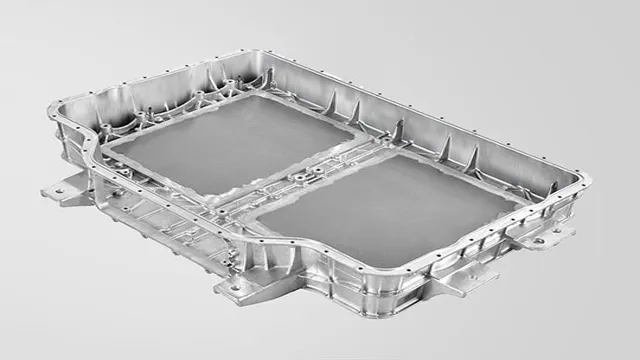

Technology Used in Electric Car Batteries

Batteries used in electric cars in India have come a long way in the past years, thanks to advancements in technology and research. Lithium-ion batteries are the most commonly used ones in electric cars. They are lightweight, have high energy density, and are rechargeable.

However, the use of nickel-metal hydride batteries is also prevalent in some models, especially in hybrid vehicles. These batteries are known for their durability and long lifespan. Additionally, solid-state batteries are also making their way into the market due to their enhanced safety features, increased storage capacity, and faster charging times.

With the increasing demand for electric cars, the focus has shifted towards making batteries that are more sustainable and eco-friendly. Manufacturers are developing new chemistries and materials to enhance the performance of batteries, reduce their environmental impact, and lower their costs. For instance, new materials such as silicon and lithium-sulfur are being used to improve the energy density of batteries, while recycled materials and second-life applications are being explored to reduce their carbon footprint.

In conclusion, batteries used in electric cars in India are evolving, becoming more advanced and sustainable. Lithium-ion and nickel-metal hydride batteries are still widely used, but solid-state batteries are expected to replace them in the near future. As technology continues to advance, we can expect more efficient, powerful, and eco-friendly batteries to emerge, driving the growth of the electric car market even further.

Comparison of Battery Types

Electric car batteries employ various technologies to store and deliver power. The most widely used battery types in electric vehicles are Lithium-ion (Li-ion) and Nickel-Metal Hydride (NiMH) batteries. Lithium-ion batteries are lighter and offer a higher energy density than NiMH batteries, allowing electric cars to go further on a single charge.

Additionally, Li-ion batteries have a longer lifespan and charge faster than NiMH batteries. However, NiMH batteries are less expensive than Li-ion batteries and are known for their reliability and safety. Other battery technologies, such as solid-state and flow batteries, are also being explored as potential options for electric car batteries.

Solid-state batteries use solid electrodes and a solid electrolyte, offering a high energy density and increased safety, while flow batteries use liquid electrolytes in external tanks, providing the ability to recharge quickly without having to wait for the battery to charge fully. As technology continues to advance, it is likely that we will see even more innovative battery technologies emerge for electric cars.

Manufacturers of Electric Car Batteries in India

Electric Car Batteries in India Electric car batteries have come a long way since their inception. Advancements in technology have led to the development of more efficient and powerful batteries, making them a viable alternative to traditional vehicles. In India, several manufacturers are producing electric car batteries to meet the growing demand for eco-friendly transportation.

The technology used in these batteries primarily revolves around Lithium-ion, which is known for its high energy density, low self-discharge rate, and longer lifespan. This technology has revolutionized the electric car industry, making it both reliable and economical. With the Indian government’s push for electric vehicles’ adoption, the demand for electric car batteries is set to further increase.

This has led to new players entering the market, promoting innovation and efficiency. With the growing focus on sustainable development, electric car batteries in India have a promising future.

Challenges Faced in Adopting Electric Cars in India

The adoption of electric cars in India faces several challenges, and one of them is related to the batteries used in these vehicles. Most Indian electric cars run on lithium-ion batteries, which manufacturing industries import from other countries. This makes these batteries and electric cars’ prices quite steep, making them affordable only for the upper-middle-class segment of society.

However, this limitation has been overcome by some Indian companies who have started producing lithium-ion batteries locally. They are also working towards improving the battery’s lifespan, making it easier to recharge, and recycling the used batteries to reduce e-waste. India’s shift to electric cars will create opportunities for the country to decrease dependence on fossil fuels and reduce pollution.

To encourage the adoption of electric cars, the government has introduced several policies that offer tax benefits and incentives. Although this transition is slow, it is expected that in the long term, electric cars will gain popularity in India, eventually becoming a viable alternative to traditional petrol/diesel vehicles.

Limitations of Battery Technology in India

The switch from gasoline cars to electric cars has been slow in India due to the limitations of battery technology. One of the major challenges faced in adopting electric cars is the high cost of batteries. This is because the manufacturing of lithium-ion batteries, which is the most popular type used in electric cars, requires rare earth metals that are expensive.

Furthermore, the lithium-ion batteries used in electric cars have a lower energy density compared to gasoline, requiring larger batteries to cover the same distance. This results in an even higher cost of production. Moreover, the lack of charging infrastructure in India is another challenge to the widespread adoption of electric cars.

In comparison to petrol stations, charging stations are still scarce and not widely distributed. This results in inconvenience and range anxiety for electric car owners. There is also an insufficient number of skilled professionals who can provide maintenance and repair services for electric cars, despite the increasing demand for them.

Despite the challenges, India’s efforts towards electric vehicles have been growing. The Indian government has set a target of 30% adoption of electric cars by 2030 and has encouraged manufacturers to produce electric vehicles. The development of new battery technology with better energy density and cost efficiency is also underway.

With these efforts, it is expected that the adoption of electric cars in India will increase in the upcoming years, despite the challenges faced.

Infrastructure Needed for Widespread Adoption of Electric Cars

Electric Cars India has been working diligently towards adopting electric cars as a means of sustainable urban transportation, but it is faced with several challenges. One of the most significant hurdles is the lack of adequate infrastructure needed for electric cars to operate effectively. This includes a reliable network of charging stations that are easily accessible to all electric car users.

The government has taken an initiative to install these stations across the country, but the progress is slow due to a shortage of capital. Moreover, customers have limited choices of electric cars to choose from in the Indian market as most auto manufacturers have been slow to produce electric cars. Economical pricing remains yet another obstacle in attaining the desired adoption rate.

However, there are positive signs of change as the demand for electric mobility is increasing in urban areas. The rise in demand will help build the necessary infrastructure, push manufactures to produce affordable electric cars with better range capacity, and encourage the gradual switch to electric cars.

Future Development of Electric Car Batteries in India

Batteries used in electric cars in India have come a long way, and the future holds even greater promise for their development. With the push towards a more sustainable future, there is a growing demand for eco-friendly modes of transport, and electric cars are leading the way. To keep up with this demand, the batteries used in these cars need to become more efficient, have greater range and last longer.

This is where the future development of electric car batteries in India comes into play. Innovative battery technologies such as solid-state batteries and lithium-sulfur batteries are being developed, which promise to provide greater energy density, longer life and a much faster charging time than today’s mainstay lithium-ion batteries. The government has also announced incentives for the development of electric vehicles, which will encourage the growth of this market and provide impetus for further innovation in battery technology.

These efforts are sure to pave the way for the widespread adoption of electric cars in India, and the batteries that power them will continue to become more advanced and efficient.

Conclusion

In conclusion, batteries used in electric cars in India are like the fuel tanks of traditional cars. They may not contain gasoline or diesel, but they power the vehicle just the same. And just like fuel tanks, the cost of replacing or upgrading a battery can be a major expense.

But with advancements in technology and a growing emphasis on sustainability, electric cars and their batteries are poised to drive us towards a brighter, greener future. So let’s charge forward and embrace the power of electric!

FAQs

What type of batteries are used in electric cars in India?

The most commonly used batteries in electric cars in India are Lithium-ion batteries.

How long does the battery of an electric car in India last before needing replacement?

The lifespan of an electric car’s battery depends on several factors, including usage, charging, and maintenance. However, most electric car batteries are rated to last for 8-10 years or 80,000-100,000 miles.

Is it expensive to replace the battery in an electric car in India?

Battery replacement costs for electric cars in India vary depending on the make and model of the car, as well as the type of battery. However, on average, it can cost between Rs. 1.5 to 3 lakhs to replace the battery in an electric car in India.

Can the batteries in an electric car in India be charged using a regular power outlet?

Yes, electric car batteries in India can be charged using a regular power outlet. However, it may take longer to charge the battery fully compared to using a Level 2 charging station or a DC fast charger.