Power Vs. Performance: Unpacking the Trade-Offs of Battery Weight in Electric Cars

Electric cars have taken the world by storm, and for a good reason. They are environmentally friendly, cost-efficient, and have the potential to revolutionize the way we think about cars. However, electric car battery weight is something that often goes unnoticed by the average consumer.

In this blog, we will take a closer look at the impacts and insights of electric car battery weight. How does the weight affect the car’s performance? Is there a significant difference in battery weight among various electric car brands? And, most importantly, how does battery weight impact the environment? These questions will be answered and more in this insightful read. So, fasten your seatbelts, and let’s dive into the fascinating world of electric car battery weight!

Introduction: Understanding Battery Weight in EVs

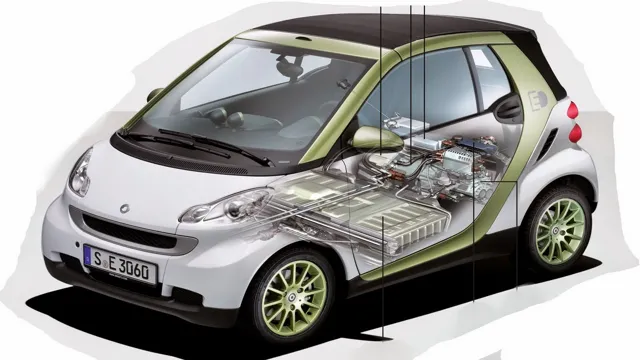

When you think of electric cars, you might think of sleek designs and environmentally-friendly driving. But have you ever considered the weight of the batteries that power these vehicles? Battery weight in electric cars is a crucial factor that impacts not only the performance but also the safety and cost of these cars. With the large amount of energy required to power an electric car, the battery pack can account for up to a third of the vehicle’s total weight.

This can have an impact on acceleration, handling, and range, as heavier batteries require more power to move the vehicle. Additionally, the weight distribution of the battery pack affects the car’s center of gravity, which can impact handling and safety. As technology advances, manufacturers are working to reduce battery weight without sacrificing performance, which can help make electric vehicles more accessible and appealing to a wider audience.

The Basics of EV Battery Weight

When it comes to electric vehicles (EVs), many people focus on the battery as the heart of the car. However, the weight of the battery is just as important as the power it provides. In fact, EV battery weight can have a significant impact on the car’s overall performance, including its range and speed.

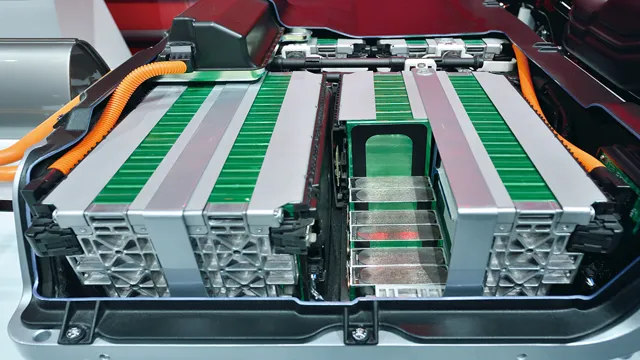

So, what exactly makes up the weight of an EV battery? Well, it’s primarily the combination of the battery cells, which are typically made up of lithium-ion, and the casing that holds them. Depending on the size and capacity of the battery, this weight can range from a few hundred pounds to over a thousand pounds. But why does this matter? Well, the heavier the battery, the more energy is required to move the car, which can result in reduced range.

This is why many EV manufacturers are constantly looking for ways to make the batteries lighter without sacrificing performance. By reducing the weight of the battery, the car can be more efficient, resulting in better range and speed.

Factors that Affect EV Battery Weight

When it comes to electric vehicles (EVs), battery weight is a crucial factor to consider. The battery is the heart of an EV, and it powers the electric motor. The weight of the battery can impact many aspects of the vehicle, including its range, performance, and overall efficiency.

Factors that affect EV battery weight include the type of battery, its capacity, and the materials used to produce it. Lithium-Ion batteries are commonly used in EVs, and they vary in weight depending on their capacity. The higher the battery’s capacity, the heavier it will be.

Additionally, the materials used to manufacture the battery can impact its weight. Manufacturers are continually working to develop lightweight materials that will improve the efficiency of EVs. By reducing the weight of the battery, EV manufacturers can increase the vehicle’s range and improve its performance.

Impacts of Battery Weight on EV Performance

Battery weight in electric cars can have a significant impact on the performance of the vehicle. The heavier the battery, the more energy is needed to move the car, which can result in decreased acceleration, reduced range, and lower overall efficiency. Car manufacturers are constantly striving to develop lighter batteries, but at the same time, they must maintain high levels of safety and durability.

This is a delicate balance, as a battery that is too light may not provide enough power for the vehicle, while a battery that is too heavy can significantly reduce performance. Drivers looking to purchase an electric car should consider the weight of the battery when making their decision, as it can have a noticeable impact on the vehicle’s performance and overall driving experience.

Range Anxiety and Battery Weight

Battery weight is a significant consideration for electric vehicle performance and range anxiety. The weight of the battery pack affects not only the vehicle’s range, but also its handling, acceleration, and overall efficiency. As battery technology advances, manufacturers are finding ways to reduce battery weight while maintaining or improving their performance.

A lighter battery pack translates into a longer range and higher efficiency, allowing drivers to travel further without stopping to recharge. However, a lighter battery may also result in reduced power output and acceleration, which could impact the overall driving experience. As such, finding the right balance between weight and performance is crucial for manufacturers to address the range anxiety concerns of potential EV consumers.

Handling and Suspension in Heavy Electric Cars

Electric cars are becoming increasingly popular due to their environmental benefits and cost-effective nature. However, as the weight of the battery pack increases, it can have an impact on the car’s handling and suspension. The battery in an electric car can weigh up to 1000 pounds or more, which significantly adds to the vehicle’s overall weight.

This additional weight can affect the car’s center of gravity and cause it to lean more when turning corners, resulting in a less stable ride. To solve this problem, manufacturers are focusing on developing suspension systems that can handle the heavy weight. These systems use different materials, such as carbon fiber and aluminum, to ensure that the car can handle the extra weight while still providing a smooth ride.

Additionally, car manufacturers are working on developing more advanced steering and brake systems that can compensate for the additional weight of the battery pack. It’s essential to consider the weight of the battery when purchasing an electric car to ensure that you get a model that provides a comfortable and stable ride.

Acceleration and Top Speed Implications of Battery Weight

Battery weight is one of the most significant factors that can influence the performance of electric vehicles (EVs). Electric motors require a lot of energy to accelerate and move an automobile, and battery weight has a significant impact on the acceleration and top speed of the car. The heavier the battery pack, the more energy it takes to accelerate and move the vehicle.

This means that EVs with lighter battery packs have a performance advantage as they can accelerate faster and achieve higher speeds. On the other hand, heavier battery packs decrease the overall efficiency of the EV, reducing range and overall performance. Therefore, vehicle manufacturers are continuously striving to improve battery technology to decrease weight and increase performance, resulting in faster and more efficient EVs.

So, in essence, battery weight is a crucial factor in determining the performance of an EV that can make or break a car’s performance on the road.

Battery Weight Reduction Methods and Innovations

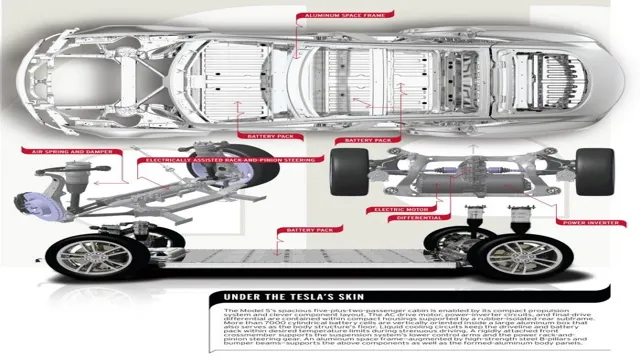

Battery weight is a crucial factor that affects the efficiency and performance of electric vehicles. Car manufacturers are continuously innovating and implementing various methods to reduce battery weight and increase capacity. One of the latest innovations is the use of solid-state batteries, which are lighter and have a higher energy density than traditional lithium-ion batteries.

Another technique is using lightweight materials, such as aluminum and carbon fiber, in the construction of battery packs. Additionally, manufacturers are optimizing the design and placement of batteries to reduce weight and improve handling. The use of AI and machine learning algorithms is also becoming popular in predicting battery performance, which can help in reducing battery size and weight.

With these new technologies and innovations, the future of electric cars looks bright, and we can expect to see even lighter, more energy-dense batteries in the years to come.

Lightweight Materials and Components in EVs

When it comes to electric vehicles (EVs), one of the biggest challenges faced by manufacturers is battery weight. However, there are many innovative methods and materials emerging to help reduce the weight of EV batteries and, in turn, increase their range. One approach is to incorporate lightweight materials such as high-strength aluminum and carbon fiber into the battery casing and other components.

Another method is to use silicon-based anodes instead of traditional graphite ones, which can provide a higher energy density and reduce the amount of lithium needed in the battery. Finally, companies like Tesla are experimenting with new battery chemistries, such as lithium-sulfur, that promise to be lighter, cheaper, and more efficient than current battery technologies. By reducing the weight of EV batteries, manufacturers can offer vehicles with longer ranges, faster acceleration, and better handling, all while reducing their carbon footprints.

Modular Battery Designs: A Solution to Heavy Batteries?

Modular Battery Design. Modular battery designs are becoming popular in various industries due to their ability to reduce battery weight. Instead of having a single large battery, modular designs consist of several smaller batteries that can be added or removed depending on power requirements.

This allows for flexibility in the power supply as well as ease of maintenance and replacement. The use of lightweight materials in the battery casing also reduces overall weight. Furthermore, advancements in nanotechnology and materials science are being utilized to create high-performance batteries with lower weight.

All of these innovations are leading to more sustainable and cost-effective battery designs that can be used in a wide range of applications. Overall, modular battery designs present an innovative solution to the issue of heavy batteries, paving the way for a greener and more efficient future.

Conclusion: Balancing Weight and Performance in EVs

In summary, the weight of batteries in electric cars might seem like a negative factor, but it ultimately paves the way for a smarter and greener future. Plus, who needs to go to the gym when you can lift your car’s battery and get a workout in at the same time?”

FAQs

How does the weight of the battery impact the performance of an electric car?

The weight of the battery can have a significant impact on the performance of an electric car. A heavier battery may reduce the range of the car and affect its acceleration and handling.

How much does the battery typically weigh in an electric car?

The weight of the battery in an electric car can vary depending on the size of the battery and the type of car. Generally, batteries can weigh anywhere from a few hundred pounds to over a thousand pounds.

Are there any advancements being made in battery technology that can reduce the weight of electric car batteries?

Yes, there are ongoing advancements in battery technology that aim to reduce the weight of electric car batteries. These include the development of new materials and designs that can increase energy density and reduce overall weight.

What impact does the weight of the battery have on the overall cost of an electric car?

The weight of the battery can impact the overall cost of an electric car, as heavier batteries may require more expensive materials and add to the manufacturing and transportation costs. However, advancements in battery technology may also help to reduce the cost of producing lighter batteries.