Rev Up Your Ride: A Step-by-Step Guide to Building Your Own Electric Car Battery

Have you ever considered building your own electric car battery? Creating a DIY electric car battery may seem like an overwhelming task, but it’s actually much simpler than you might think. Plus, it’s a great way to save money in the long run and reduce your carbon footprint. In this blog post, we’ll cover the basics of how you can build your own electric car battery from scratch.

We’ll also explore some of the different components you’ll need and provide tips for ensuring your battery is reliable and long-lasting. So, if you’re ready to dive into the world of sustainable transportation, let’s get started!

Introduction

Have you ever considered building your own electric car battery? With advances in technology and the innovation of DIY enthusiasts, it’s becoming more and more feasible for individuals to construct their own batteries. Not only is this a cost-effective option, but it also allows for customization and the ability to control the materials and components used. However, building your own electric car battery requires a certain level of technical knowledge and safety precautions must be taken.

It’s important to do extensive research and consult with professionals before embarking on this project. But for those up to the challenge, the end result could be a reliable and unique electric car battery that meets your specific needs and preferences.

Understanding the Basics of Electric Car Batteries

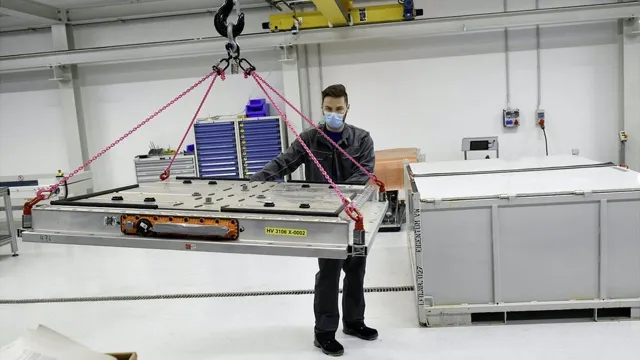

Electric Car Batteries Introduction: Electric cars are becoming increasingly popular with their eco-friendly credentials and smooth rides. However, one of the key components that differentiate them from their gasoline counterparts are the batteries that power them. Understanding the basics of electric car batteries is important for both the average consumer and car enthusiasts alike.

These batteries are not only the key to the car’s performance, but they also make up a significant portion of the car’s cost. Therefore, it is essential to know how they work and what their limitations are in terms of range and charging time. In this article, we will delve deeper into the inner workings of electric car batteries, exploring the science behind them and the factors that affect their efficiency.

So, let’s get started!

Why Build Your Own Electric Car Battery?

Building your own electric car battery might seem like a daunting task, but it can be a rewarding experience with many benefits. Not only can it save you money in the long run, but it also gives you complete control over the quality of your battery and allows you to customize it to fit your specific needs. When building your own electric car battery, you have the option to choose high-quality components and ensure that the battery is built to last.

Additionally, you can customize the size and capacity of the battery to fit your particular driving style or range requirements. With the rising popularity of electric vehicles, building your own battery can be a way to be a part of the transition to a greener future. So, why not take on the challenge of building your own electric car battery and enjoy the benefits it can bring?

Getting Started

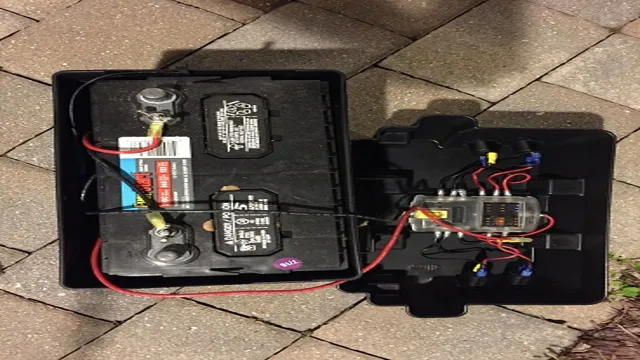

Are you interested in building your own electric car battery? While this might seem like an overwhelming task, it’s actually something that many people have successfully accomplished. The first step is to do your research and become familiar with the different components of an electric car battery, including the cells, BMS (battery management system), and wiring. From there, you can begin to source quality parts and tools, such as a multimeter and soldering iron.

It’s important to have a clear understanding of the process and proper safety precautions before beginning any work on your battery. Building your own electric car battery can be a rewarding and cost-effective alternative to purchasing a pre-made battery system. With the right knowledge and tools, you can create a functional and efficient battery that will power your electric car for years to come.

Choosing the Right Components

When it comes to building a PC, choosing the right components can feel overwhelming. Where do you start? First, consider your needs. Are you a gamer? A content creator? A student on a budget? Next, decide on a budget that fits those needs.

From there, you can start researching components. Look for high-quality components that fit your budget. Pay close attention to compatibility to ensure everything will work smoothly together.

Don’t be afraid to ask for help or read reviews from other users. The most important thing is to choose components that will work together to create a powerful and efficient system tailored to your needs. With the right components, you’ll have a PC that can handle anything you throw at it.

Gathering the Necessary Tools and Materials

As you get ready to start your project, it’s essential to gather all the necessary tools and materials that you’ll need to bring your vision to life. Make sure you have a detailed list of everything you’ll need for the job and check it twice before you begin. Don’t hesitate to ask someone with more experience in the project you’re undertaking for advice on the best materials and tools to use.

Pay close attention to the materials’ quality to avoid any issues during and after construction. Consider the durability, the project demands, and how easy they will be to work with. Look for the best bargains online or in your local hardware stores and make sure you have everything you need for your project.

Remember, quality materials and tools are the secret to creating something that has both functionality and beauty while standing the test of time. So, invest in top-quality, durable materials that will ensure your project comes out perfectly the first time around.

Assembling the Battery Pack

Starting to assemble a battery pack for your project can be a bit daunting, but with the right tools and some basic knowledge, it’s completely doable. First things first, gather all your materials and make sure you have everything you need. This will typically include battery cells, nickel strips, a spot welder, a battery management system (BMS), and heat shrink wrap.

Once you have all the materials, start by aligning the battery cells in the desired configuration and then connect them using the nickel strips. The next step is to weld the strips to the cell terminals using the spot welder. Be sure to use the right power settings and avoid creating too much heat, which could damage the cells.

After all the cells are connected, you can then install the BMS and wrap the pack in heat shrink to protect it from damage. With these basic steps, you’re well on your way to creating a functional battery pack that will power your project.

Testing and Maintenance

If you’re planning to build your own electric car battery, testing and maintenance should be one of your top priorities. You need to ensure that your battery is performing efficiently and effectively, and that it remains in good condition for many years. One important aspect of testing is monitoring the battery’s temperature and voltage levels.

Overheating can cause damage to the battery, while low voltage can affect its performance. You should also perform maintenance tasks, such as cleaning the terminals and checking for corrosion. Regular maintenance can prevent problems from occurring in the first place, and can extend the life of your battery.

When building your own electric car battery, it’s important to be careful and thorough, and to pay close attention to the testing and maintenance process.

Testing the Battery Pack

Testing the Battery Pack Testing and maintenance of your battery pack is crucial to ensure its efficiency and longevity. Before testing your battery pack, it’s important to make sure it is disconnected from any device or charging source. You can use a multimeter to test the voltage of each cell in the battery pack.

If you notice that one or more cells have a significantly lower voltage than the others, it may be time to replace them. Another way to test your battery pack is to charge it fully and then discharge it completely while measuring the time it takes to do so. If it takes significantly less time than it did when the battery was new, it may be time for replacement.

Regular maintenance, such as cleaning the contacts and checking for any signs of damage, is also important in prolonging the life of your battery pack. By taking the time to test and maintain your battery pack, you can ensure that it provides reliable power when you need it.

Maintenance and Troubleshooting Tips

When it comes to testing and maintenance for your equipment, it’s important to have a proper checklist in place. This could include visual inspections, checking calibration, and testing for any faults or malfunctions. Regular testing will ensure that your equipment is working properly and address any issues before they become major problems.

In addition to testing, regular maintenance is crucial for preventing breakdowns and extending the lifespan of your equipment. This could include tasks like cleaning, lubrication, and replacing any worn-out parts. It’s also important to keep track of any repairs or upgrades that have been done and when they were completed.

By taking these steps, you can ensure that your equipment is functioning properly and avoid costly downtime or repairs. So, make testing and maintenance a priority and watch your equipment perform at its best.

Conclusion

In conclusion, building your own electric car battery is a challenging yet rewarding endeavor. It requires patience, skill, and perseverance, but the end result is a cost-effective and eco-friendly mode of transportation. Plus, you’ll have bragging rights knowing that you built your car’s power source from scratch.

So, if you’re feeling electrically inclined, roll up your sleeves and start building! Who knows, maybe Elon Musk will be calling you for a job soon.

FAQs

What materials do I need to build my own electric car battery?

To build your own electric car battery, you will need lithium-ion cells, battery management system, nickel strips, wires, and a casing.

Can I use recycled batteries for my DIY electric car battery?

It is possible to use recycled batteries to build your own electric car battery, but it is important to ensure that the cells are in good condition and have similar performance characteristics.

How long does it take to build a DIY electric car battery?

The time it takes to build your own electric car battery will depend on your experience level, the complexity of the design, and the availability of materials. It can take anywhere from a few days to several weeks.

Is it cost-effective to build my own electric car battery?

Building your own electric car battery can be cost-effective in the long run, as you can customize the design based on your needs and potentially save money on repairs and replacements. However, it may require a significant initial investment in materials and tools.