Battery Boost: Can We Keep Up With the Growing Demand for EV Batteries?

Electric car batteries have revolutionized the automotive industry and have spurred environmental-conscious buying decisions from consumers worldwide. However, with the increasing demand for electric cars, the demand for more efficient and cost-effective batteries is growing at an even faster rate. To meet this demand, automakers and battery manufacturers are developing more advanced battery technologies that will give electric cars longer driving ranges with faster charging times.

So how exactly are they meeting the ever-increasing demand for electric car batteries? Keep reading to find out.

Current Production Levels

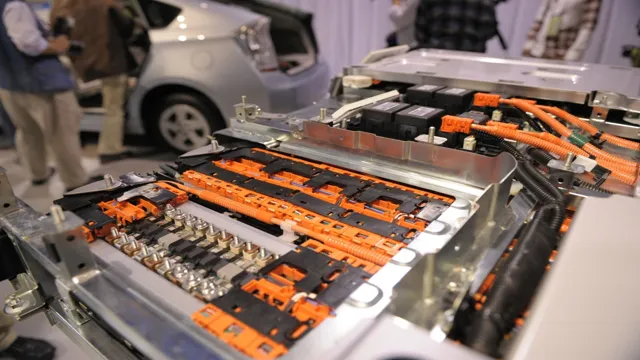

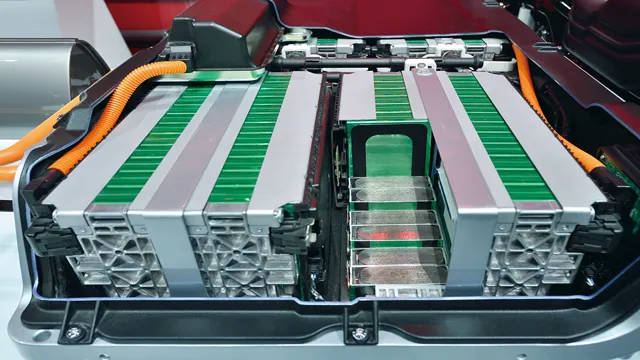

As the popularity of electric cars continues to grow, questions arise about whether we can produce enough batteries to meet the demand. Current production levels suggest that we may not be able to keep up. Lithium-ion batteries, which are the most common type used in electric cars, require a significant amount of rare earth minerals and metals to produce.

This has led to fears that we may face a shortage in the supply chain as demand continues to rise. However, there is hope that new technologies and innovations in battery production will help address these concerns. The key will be finding ways to increase production without compromising on quality or environmental and social responsibility.

The good news is that there are already many companies working towards this goal, and with continued investment and research, we may be able to meet the growing demand for batteries and electric vehicles.

Global Battery Production

Global Battery Production Currently, global battery production is experiencing rapid growth due to an increase in demand from the electric vehicle industry and renewable energy storage. In 2020, global battery production capacity exceeded 530 GWh, and it is projected to reach 740 GWh by 202 China is currently the largest producer of batteries, accounting for approximately 70% of global production in 2020.

However, other countries such as Japan and South Korea are also significant players in the industry. While lithium-ion batteries are currently the dominant technology, there is a push to develop other types of batteries such as solid-state batteries, which could offer longer lifetimes and higher energy densities. Overall, the growth in battery production is a positive development for the transition away from fossil fuels and towards a sustainable energy future.

Battery Materials Availability

Battery materials are becoming increasingly important due to the growing demand for electric vehicles. However, the availability of these materials is a concern. Currently, the production levels of battery materials such as lithium, cobalt, and nickel are not keeping up with the demand.

This is partly due to the limited reserves of these materials and the challenges associated with extracting them. Moreover, the mining process itself is environmentally harmful and causes social issues. The high demand for these materials has also led to price fluctuations, which can be seen as the battery materials market is quite volatile.

Despite these challenges, there are efforts being made to obtain these materials sustainably and reduce the reliance on them. For example, researchers are exploring alternative materials, such as magnesium and sodium, which are more abundant and eco-friendly. However, there is still a long way to go in terms of ensuring a steady supply of battery materials for our rapidly transitioning world.

Future Production Capacity

Can we make enough batteries for electric cars? Absolutely. While there are certainly challenges we face in scaling production levels to meet the ever-increasing demand for electric vehicles, the future looks bright. Some of the world’s largest automakers are investing heavily in battery technology, and major breakthroughs in research and development are happening at an unprecedented rate.

Additionally, emerging markets for second-life batteries and battery recycling offer further opportunities to reduce waste and increase sustainability. We may not be there yet, but with continued collaboration and innovation, we will undoubtedly rise to the challenge of meeting this demand.

Investments in Battery Manufacturing

Investments in battery manufacturing continue to increase as demand for electric vehicles rises. These investments are aimed at increasing future production capacity, as companies aim to meet the growing demand for electric vehicles. One significant investment was made by Tesla, who announced plans to build a battery manufacturing plant in Texas.

This new factory is expected to start producing batteries by the end of 2021, and will ultimately become one of the largest battery manufacturing plants in the world. Other companies, such as LG Chem, have also announced plans to increase their production capacity. This increased capacity will not only allow for more electric vehicles to be produced, but will also help to lower production costs, making electric vehicles more affordable for consumers.

As the transition to electric vehicles continues, investments in battery manufacturing will play a crucial role in ensuring a sustainable future.

Technological Advancements in Battery Production

Battery production has come a long way since its inception, and with continuous technological advancements, the future production capacity looks very promising. With an increased demand for batteries in electric vehicles and storage, the industry has shifted its focus to develop batteries that are quicker and cheaper to produce, have longer lifespans, and are more energy-dense. One significant breakthrough in battery production is the use of solid-state batteries, which have a higher energy density than the traditional lithium-ion batteries and are less likely to catch fire.

This has the potential to revolutionize the automotive industry as well as the renewable energy sector. Other advancements include the use of AI and machine learning in battery production to optimize the manufacturing process further and reduce costs. With all these developments, the future production capacity of batteries is set to increase tremendously, making them more accessible and affordable for households and industries alike.

Alternative Battery Materials

As we look towards a future where alternative battery materials may be the norm, questions arise about the production capacity of these materials. While some materials, such as lithium, have well-established supply chains, others like cobalt and nickel may face challenges in scaling up production. However, advancements in technology and increased investment in research and development could help to address these limitations.

For example, scientists are exploring the use of polymers or organic materials as an alternative to traditional metal-based batteries, which could lead to more sustainable and scalable production options. It’s important to keep in mind that while alternative battery materials show promise for reducing the environmental impact of current battery technology, there are still many challenges to be solved in order to ensure that production can meet demand in the future.

Conclusion

Well, it seems that the answer to the question “can we make enough batteries for electric cars?” is not a simple yes or no. While technology and innovation are constantly improving, it will take a significant amount of time and resources to produce enough batteries to fully transition to electric vehicles on a large scale. However, with continued investment and focus on sustainable energy solutions, the future of electric cars is looking bright.

So, the next time someone asks if we can make enough batteries for electric cars, just reply with a witty confidence and say, “We’re charging ahead!”

Meeting the Demand is Possible

When it comes to meeting the demand for goods and services, many factors come into play. However, the good news is that future production capacity is promising. Thanks to advancements in technology and infrastructure improvements, manufacturers and service providers have more tools at their disposal to increase their production levels.

Automation, for example, has made it possible to produce goods and services faster and more efficiently. Additionally, many industries are investing in modern infrastructure and supply chain management systems that help reduce costs and streamline processes. With these developments, businesses can increase their production capacity, meet demand, and remain competitive in their respective markets.

So, while demand may fluctuate over time, the future production capacity looks bright, and businesses have the tools and resources they need to continue meeting the needs of their customers.

Continuous Innovation is Key

In today’s fast-paced business world, production capacity is more critical than ever. To stay competitive, companies must continuously innovate and improve their production processes to increase capacity and efficiency. This means investing in new technologies and streamlining workflow to reduce downtime and improve quality control.

But it’s not just about the machines and equipment; it’s also about the people. Organizations need to cultivate a culture of innovation that encourages employees to come up with new ideas and methods to do things better and faster. Moreover, future production capacity requires a deep understanding of consumer needs and preferences.

Companies must constantly be listening to their customers and monitoring market trends to identify opportunities for innovation. This means being open to change and taking risks to stay ahead of the curve. It’s not just about keeping up with the competition; it’s about anticipating their needs before they do.

In conclusion, continuous innovation is the key to future production capacity. Companies that are able to adapt quickly to changing circumstances and embrace new technologies and ideas will be the ones that thrive in the years to come. By fostering a culture of innovation, investing in new technologies, and staying close to their customers, organizations can position themselves for success and growth in the increasingly complex and competitive business landscape.

FAQs

How many batteries are needed for an electric car?

An electric car typically requires multiple lithium-ion batteries with a total weight as much as 500 to 1,000 pounds, depending on the car model.

What is the current production capacity for electric car batteries?

The current global production capacity for electric car batteries is about 300 gigawatt-hours per year, but experts believe it must increase to at least 1,000 gigawatt-hours by 2025 to meet growing demand.

Can we recycle lithium-ion batteries from electric cars?

Yes, lithium-ion batteries from electric cars can be recycled to recover valuable metals such as cobalt, nickel, and lithium, which can be used to produce new batteries or other products.

How do electric car batteries compare in cost to traditional gasoline-powered vehicles?

Although electric car batteries are still expensive, the cost has decreased rapidly over the past decade and is expected to continue falling as technology advances and production scales up. Additionally, electric cars save a significant amount of money on fuel costs over their lifespan.