Is It Safe to Use Electrical Tape on Car Battery Terminals? Expert Answers Inside

As a car owner, the last thing you want is to end up stranded on the side of the road with a dead battery. Car batteries are susceptible to damage over time, especially if their terminals are not adequately protected. One of the best ways to protect your car battery terminals is by using electrical tape.

This type of tape is specifically designed to prevent moisture, dust, and other contaminants from getting into your battery terminals, which can cause corrosion and deterioration. Whether you are a seasoned driver or a newbie behind the wheel, keep reading to learn more about the benefits of using electrical tape to protect your car battery, and how to apply it correctly.

Importance of Protecting Terminals

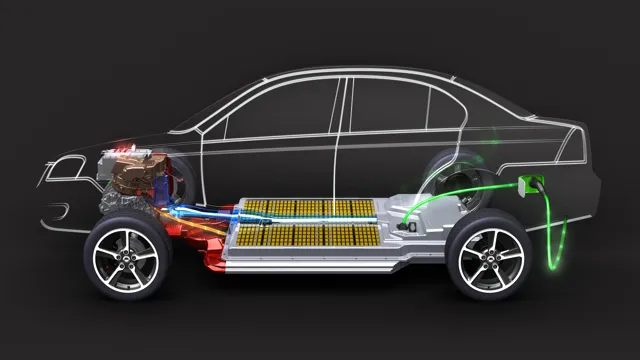

Yes, you can put electrical tape on car battery terminals, but it is always best to use proper terminal protectors to ensure maximum protection. The terminals on your car battery are vital components that keep your vehicle running. They connect the battery to the car’s electrical system, enabling it to start and operate.

If your terminals are damaged or corroded, it can cause your car to not start or even damage the electrical system. Electrical tape is not designed to protect terminals from corrosion or damage, so it should only be used as a temporary solution until proper protection can be applied. Terminal protectors are specifically designed for this purpose and should be applied to all battery terminals to prevent corrosion from forming and damaging your battery.

Neglecting to protect your terminals can result in costly repairs and can even shorten the lifespan of your car battery. So, while using electrical tape to cover the terminals may seem like a quick fix, it is always best to invest in proper terminal protectors for the long-term health of your vehicle.

Prevent Short-circuit

When it comes to electrical devices, short-circuits are never a good thing. That’s why protecting terminals is so important for preventing such accidents. Short-circuits occur when two electrical terminals come into contact with each other and create a surge of energy that can damage devices or even start fires.

Protecting terminals with properly installed insulation or other protective measures can help prevent this from happening. So, whether you’re working with electronics at home or in a professional setting, make sure you take the necessary steps to protect your terminals and prevent short-circuits from occurring. It’s a small task that can make a big difference in safety and the longevity of your devices.

Limit Corrosion

Protecting terminals is crucial to limit corrosion and maintain the longevity of electrical systems. Corrosion can lead to damage and poor connectivity, causing failures and high repair costs. Protecting terminals may include using corrosion-resistant materials or using protective coatings to prevent the accumulation of moisture and dirt.

It is important to regularly inspect and maintain these protective measures to ensure they continue to function effectively. Neglecting to protect terminals can lead to significant downtime and lost revenue, as well as potentially hazardous situations. Don’t let corrosion take a toll on your equipment, take the necessary steps to protect your terminals.

Materials and Tools Needed

If you’re wondering whether you can put electrical tape on car battery terminals, the short answer is no. Electrical tape is not designed to handle the high temperatures and chemical reactions that occur around car batteries. In fact, using tape to cover battery terminals can create a fire hazard and may damage your vehicle’s electrical system.

Instead, use a proper terminal cover or protective spray that’s designed specifically for automotive use. You should also wear gloves and eye protection when working on your battery, as batteries contain dangerous chemicals that can cause burns or injury if mishandled. With the right tools and precautions, you can safely maintain your car’s battery and ensure that it operates at peak performance.

Electrical Tape

Electrical tape is a versatile tool that is used for a wide range of tasks. It is an essential item in the toolbox of electricians, DIY enthusiasts, and homeowners alike. When it comes to electrical work, safety is of the utmost importance.

Therefore, it is crucial to use high-quality electrical tape that can withstand high temperatures, moisture, and UV rays. In order to successfully use electrical tape, you will need the right tools and materials. First and foremost, you will need a good quality electrical tape that meets the necessary safety standards.

Additionally, you will need a pair of sharp scissors or a knife to cut the tape to size. It is also useful to have a clean, dry surface to work on and some tissues or a cloth to wipe away any excess adhesive. With the right tools and materials, you can ensure that your electrical work is safe and secure.

Rubbing Alcohol

When it comes to using rubbing alcohol, there are a few essential materials and tools you’ll need to have on hand. First and foremost, you’ll need a bottle of rubbing alcohol. Typically, rubbing alcohol is available in concentrations ranging from 70% to 99%, so be sure to choose the right strength for your needs.

You’ll also need some cotton balls or swabs to apply the alcohol, as well as a spray bottle if you plan to use the rubbing alcohol as a cleaning solution. Additionally, it’s essential to work in a well-ventilated area, as the fumes from rubbing alcohol can be quite strong. If you plan to use rubbing alcohol frequently, it’s also a good idea to invest in some rubber gloves to protect your hands from harsh chemicals.

Overall, by having the right materials and tools on hand, you can easily and safely use rubbing alcohol for a variety of applications.

Steps to Apply Electrical Tape

Yes, you can put electrical tape on car battery terminals. In fact, it is a good idea to do so to prevent corrosion and ensure a good electrical connection. However, it is important to follow the right steps to apply the tape correctly.

Firstly, clean the battery terminal with a wire brush to remove any dirt or corrosion. Next, wipe it down with a cloth soaked in alcohol to ensure it is completely clean and dry. Then, wrap the terminal with electrical tape, making sure to overlap the edges to create a tight seal.

Be sure to apply enough pressure with your fingers to ensure the tape adheres properly. Finally, test the connection by turning on the car and ensuring everything is functioning properly. Overall, it is a simple process that can save you a lot of trouble down the line.

Step 1: Disconnect battery

Electrical tape Before applying electrical tape, it’s important to disconnect the battery to avoid any harm or accidents. This will ensure that no electrical currents are present while working on the wiring. Once the battery is disconnected, make sure the area where you’ll be applying the tape is clean and dry.

Electrical tape is a versatile tool used for insulating, bundling, and protecting electrical objects from harsh environments and wear and tear. Applying electrical tape requires a steady hand and proper technique to ensure the tape adheres well to the surface and seals any exposed wiring. When wrapping the tape, make sure to overlap the previous layer slightly to ensure complete coverage.

It’s important to use the correct type of electrical tape for the specific job to ensure maximum protection and insulation. Overall, with the right precautions and technique, applying electrical tape to your electrical wiring can provide peace of mind knowing everything is secure and properly insulated.

Step 2: Clean terminals

When it comes to applying electrical tape, there are a few important steps you need to follow to ensure a secure and long-lasting connection. One of the most crucial steps is to clean the terminals thoroughly. Dirty or corroded terminals can interfere with the conductivity of the tape, leading to a weak and unreliable connection over time.

To clean the terminals, start by disconnecting the power source and use a wire brush or sandpaper to remove any debris or buildup. Wipe the terminals down with a clean cloth and make sure they are completely dry before proceeding with the tape application. By taking the time to clean the terminals properly, you can ensure that the electrical tape will adhere firmly and create a safe and effective connection.

Step 3: Wrap tape around terminals

After wrapping the wire with electrical tape, the next step is to wrap the tape around the terminals. This step is crucial in securing the connection and preventing any electrical mishaps from happening. Start by wrapping the tape around the base of the terminal.

Make sure to create a tight seal by pressing the tape firmly against the terminal. Afterwards, wrap the tape around the connector while ensuring that it covers the entire terminal. Again, press the tape securely to ensure that it sticks.

Repeat this step until all the terminals are covered with electrical tape. By following these steps, you can ensure that the electrical connection is secure and that the wires are protected from any damage. So, when working on any electrical wiring project, don’t forget to include wrapping the terminals with electrical tape.

Step 4: Reconnect battery

Electrical Tape To properly apply electrical tape, there are a few steps you’ll want to follow. First off, make sure you have the right tape for the job. Most electrical tape is made of PVC or vinyl, and it’s designed to be resistant to moisture, heat, and chemicals.

Once you have the tape in hand, you’ll want to clean the surface you’ll be applying it to. This will help the tape adhere more effectively. Next, place the tape at one end of the surface and pull it tightly as you wind it around.

Make sure there are no wrinkles or air bubbles as you go. If you need to overlap the tape, make sure it’s done neatly and with a slight angle to prevent it from peeling up. Finally, when you’ve finished applying the tape, give it a good rub down with your fingers to activate the adhesive.

By following these steps, you’ll be able to effectively use electrical tape to protect your electrical connections and ensure they stay safe and secure for years to come.

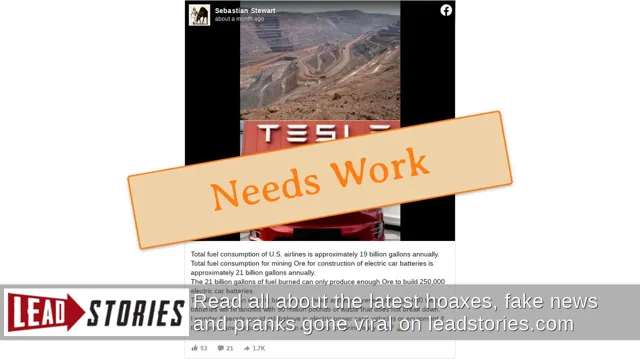

Conclusion: Electrical Tape is an Essential Tool for Battery Maintenance

In conclusion, while electrical tape may provide a temporary solution for frayed wires or small tears in insulation, it is not recommended to use it on car battery terminals. This is because the tape can easily melt or come undone due to the extreme heat and vibration under the hood, creating an even greater risk of electrical damage or even a fire hazard. So if you want to ensure the safety and reliability of your vehicle, it’s best to leave the battery maintenance to the professionals and avoid DIY fixes with electrical tape.

After all, you wouldn’t want to give your car a temporary fix only for it to go up in smoke!

FAQs

Is it safe to put electrical tape on car battery terminal?

Yes, it is safe to put electrical tape on car battery terminal. The tape helps to prevent accidental contact with the battery terminal and reduces the risk of electrical shock.

How do I apply electrical tape on car battery terminal?

First, make sure the car battery is turned off and the terminal is clean and dry. Then, wrap the terminal with electrical tape, ensuring that the tape completely covers the terminal and any exposed wires.

Can I use any type of electrical tape on car battery terminal?

No, it is recommended to use high-quality electrical tape that is specifically designed for automotive use, such as vinyl electrical tape. This type of tape is durable and can withstand exposure to heat, cold, and moisture.

How often should I replace the electrical tape on my car battery terminal?

It is recommended to check the condition of the electrical tape on your car battery terminal regularly and replace it if it becomes worn, damaged, or starts to peel. As a general rule, it’s a good idea to replace the electrical tape every 6 months to maintain optimal safety.