Reviving Your Car Battery with Electroplating: A Cost-Effective Solution for Longer Life

Car battery electroplating is a topic that may seem confusing at first, especially if you’re not familiar with the process. However, it can have a significant impact on the lifespan and performance of your vehicle’s battery. In this blog post, we’ll cover everything you need to know about car battery electroplating, including what it is, how it works, and the benefits it can provide.

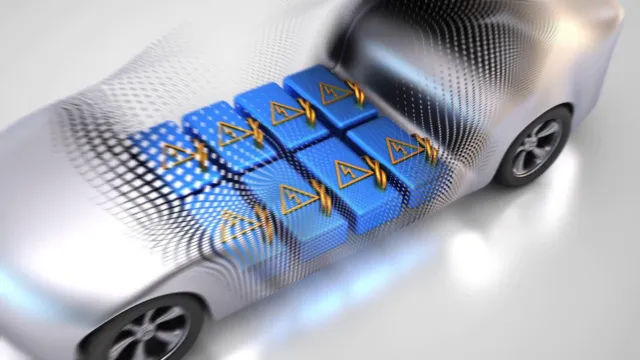

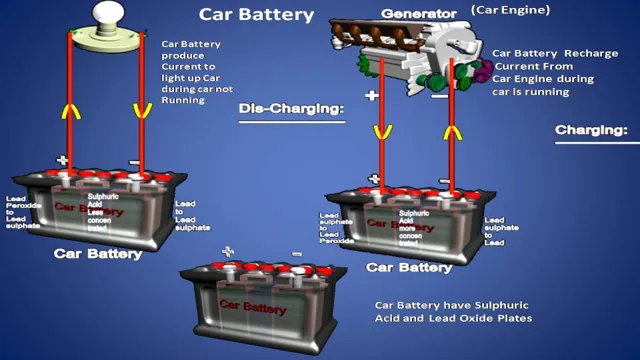

First, let’s start with the basics. What is electroplating? Simply put, electroplating is a process that involves depositing a thin layer of metal onto a surface using an electric current. In the context of car batteries, electroplating is used to coat the lead plates inside the battery with a layer of lead dioxide, which helps improve the battery’s performance and longevity.

So, why is electroplating important for car batteries? Over time, the lead plates inside a battery can become corroded and worn down, which can cause a decrease in the battery’s capacity and performance. Electroplating can help restore the lead plates to their original condition by adding a new layer of lead dioxide. This can improve the battery’s overall lifespan and performance, which is especially beneficial for those who frequently use their vehicle.

Overall, car battery electroplating is a process that can provide numerous benefits for your vehicle’s battery. From improving its performance to extending its lifespan, electroplating is a worthwhile investment for those looking to get the most out of their car battery. If you’re interested in learning more about car battery electroplating and how it can benefit your vehicle, be sure to keep reading our blog for more information.

What is Electroplating?

Car battery electroplating is a process of coating an object with a layer of metal using electrolysis. In this process, a DC current is passed through a solution called an electrolyte. The electrolyte contains metal ions that get attracted to the object, creating a layer of metal on top of it.

Car battery electroplating is commonly used to restore the surface of old or damaged car parts, such as bumpers and rims. The process not only makes the parts look like new again, but it also protects them from rust and corrosion. It’s essential to note that electroplating can be dangerous if proper safety precautions are not taken.

That’s why it’s always recommended to have the process done by professionals who have the necessary knowledge and experience. So, if you’re looking to restore the surface of your car parts, consider car battery electroplating as a cost-effective and long-lasting solution!

Definition and Process

Electroplating is a process of coating a metal object with another metal using electricity. In simpler terms, it is the process of plating one metal onto another metal surface. The process involves dipping the object to be plated, called the substrate, in a solution containing the metal ions of the plating metal.

The substrate is then connected to the negative pole of a power source, while the anode, made of the plating metal, is connected to the positive pole. When the power is turned on, the ions of the plating metal are attracted to the substrate and deposited onto its surface, forming a thin layer of the metal. The thickness of the plating depends on the duration and strength of the electric current and the chemical makeup of the solution.

Electroplating is a widely used technique in various industrial applications, and it is commonly used to enhance the appearance, durability, and performance of products such as jewelry, automotive parts, and electronic components, among others.

History of Electroplating

Electroplating Electroplating is a process that has been around for over 200 years and has become a vital part of modern manufacturing. It involves the deposition of a thin layer of metal onto a substrate using electrolysis. This process was first discovered by an Italian chemist, Luigi Brugnatelli, in 1805, who successfully plated silver onto a copper object using an electric current.

Since then, many advances have been made in the electroplating process, including the development of numerous varieties of metals that can be used for plating, like nickel, gold, and copper. Electroplating has played a crucial role in several industries, such as automobile, electronics, and jewelry, where it is used for improving the quality of materials, providing corrosion resistance, and improving the appearance of finished products. Despite the many benefits of electroplating, it also leads to several environmental concerns due to the use of toxic chemicals.

Advanced technologies and greener alternatives are being developed to mitigate the negative effects of electroplating while promoting sustainable manufacturing practices.

The Benefits of Electroplating Your Car Battery

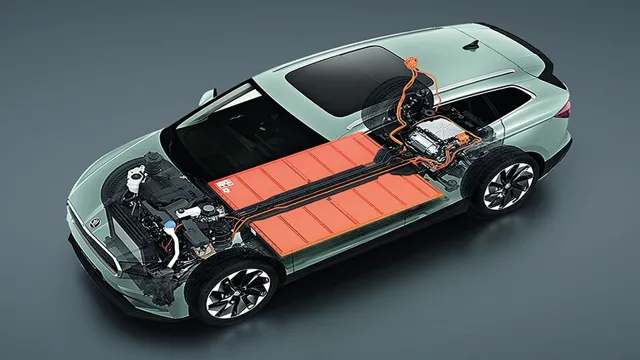

Car battery electroplating is a process where a thin layer of metal is applied to the surface of the battery, which helps to prevent corrosion and prolong its lifespan. There are several benefits of electroplating your car battery, including improved performance, increased durability, and reduced maintenance costs. Electroplating helps to reduce the amount of sulfuric acid that is lost during the charging process, which can increase the battery’s capacity and extend its life.

Additionally, electroplating can help to prevent the battery from corroding due to exposure to the elements or excessive heat. Overall, electroplating can be a cost-effective way to keep your car battery in good condition, and it is especially useful for those who live in areas with harsh weather conditions or who use their vehicles frequently. With the right maintenance and care, a properly electroplated car battery can provide reliable power for years to come.

Improved Performance

Electroplating, Car Battery, Performance If you’re wondering how to improve your car’s overall performance, electroplating your battery is an excellent place to start. This process involves coating your car battery’s metal terminals with a layer of another metal, usually nickel or copper, to improve its conductivity and protect it from corrosion. By doing this, you’ll notice smoother and consistent performance, especially during cold weather where battery performance tends to decrease.

Also, electroplating your car battery can significantly extend its lifespan, saving you a great deal on costly replacements down the road. So, if you want your car to run like a well-oiled machine and enjoy its performance to the fullest, consider electroplating your car’s battery terminals today.

Longer Lifespan

Electroplating can increase the lifespan of your car battery, providing you with a wealth of benefits that can save you time, money, and effort. One of the most significant advantages of electroplating your car battery is its longevity. By using advanced techniques such as electroplating, you can coat your battery’s internal components with an extra layer of protection.

This layer helps to mitigate the negative effects of the acid and electrolytes contained within the battery, reducing corrosion and extending the life of your battery. Additionally, this protective layer can also improve the conductivity of the battery, leading to better overall performance. By electroplating your car battery, you can save money in the long run, as you won’t need to replace your battery as frequently, and you’ll enjoy better fuel efficiency due to improved performance.

So if you’re looking to extend the lifespan of your car battery, electroplating is definitely worth considering.

Cost Savings

If you’re looking to extend the life of your car battery and save money in the process, electroplating might be the perfect solution. Electroplating involves applying a thin layer of metal coating to a base metal in order to protect it from corrosion and wear. In the case of car batteries, electroplating can help prevent corrosion of the terminals and other metal components inside the battery, which can lead to premature failure.

By electroplating your car battery, not only can you save money on expensive replacements, but you can also ensure that your battery lasts longer and performs better over time. So why not give it a try? You might be surprised by how much it can improve the performance and longevity of your car battery.

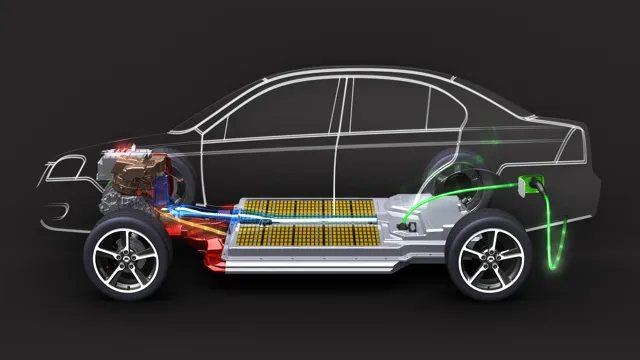

How to Electroplate Your Car Battery

Car battery electroplating is a process that coats the surface of the battery with a layer of metal to protect it and extend its lifespan. Electroplating is done by immersing the battery in a chemical solution and using an electrical current to deposit metal ions onto the surface. The most common metals used for electroplating are zinc and nickel.

Zinc is the most cost-effective option and provides good corrosion protection, while nickel provides superior corrosion resistance and durability. Electroplating can be done at home, but it requires some specialized equipment and knowledge about the process. It’s important to follow safety precautions, such as wearing protective gear and working in a well-ventilated area.

If done correctly, electroplating can help extend the life of your car battery and save you money in the long run.

Materials You Will Need

If you want to electroplate your car battery, there are several materials you will need. First, you will require a battery to electroplate, a power source that produces 12-volt voltage, a container to hold the electrolyte solution, and the solution itself. You will also need a rectifier or a DC power supply to convert the AC power from the outlet to a usable DC power.

It would be best if you had a battery charger to use as a power supply while plating, along with an anode material for the electroplating process, such as copper or nickel. Be sure to wear safety gear, such as gloves and goggles, when handling the chemicals involved in the process. To electroplate your car battery, you will need to create an electrolyte solution by mixing water and an electrolyte powder, such as Epsom salt or borax.

Once you have your solution, connect the negative end of your power supply to one end of the battery and the positive end to your anode material. Then, submerge the battery and anode in the electrolyte solution, ensuring that they do not touch. Turn on the power supply and let the electroplating process continue for several minutes or until the desired thickness of the plating is achieved.

Overall, electroplating your car battery is a relatively easy process, but it requires specific materials and attention to safety. Using the right materials and equipment can lead to excellent results and help extend the life of your car battery. With the use of the right keywords, such as electroplating and battery, you can better increase your website’s performance on search engine result pages and attract more readers interested in this topic.

Step-by-Step Guide

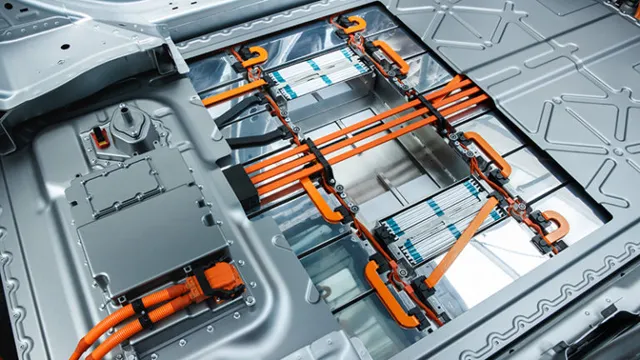

Electroplating, Car Battery Electroplating your car battery can be a cost-effective way to prolong its life and improve its performance. As a self-proclaimed DIY enthusiast, I’ve found the process to be relatively simple and straightforward. To begin, you’ll need to acquire some basic supplies like a metal plating solution, a current source (like a battery charger), and some connecting wires.

Next, you’ll want to clean and prep your battery by removing any corrosion or buildup on the terminals. You can use a mixture of baking soda and water to scrub away any gunk, being sure to rinse and dry the area thoroughly before moving on. After your battery is prepped and ready to go, you can begin the electroplating process by dipping the terminals into the plating solution and running a current through them.

The length of time you leave the terminals in the solution will depend on the strength of the current you’re using, but typically a few hours should suffice. Once you’re finished electroplating, be sure to rinse and dry the terminals again before re-installing them into your battery. Voila! Your car battery is now electroplated and ready to go.

By following these simple steps, you can extend the life of your battery and save yourself some money in the long run.

Tips for Maintaining an Electroplated Car Battery

When it comes to maintaining an electroplated car battery, there are a few things that you can do to ensure that it stays in great condition for as long as possible. First, it’s important to regularly check the battery’s voltage levels to ensure that they are within the proper range. You can do this by using a voltmeter or multimeter.

If the battery’s voltage levels are too low, you may need to charge it more often. You can also help extend the life of your electroplated car battery by keeping it clean and free of dirt and debris. Be sure to clean the battery terminals regularly, as buildup on these can cause the battery to lose its charge quickly.

Additionally, it’s a good idea to keep the battery in a cool, dry place when not in use, as excessive heat and moisture can cause damage to the electroplating. By following these simple tips, you can keep your car battery electroplating in top shape and ensure that it continues to provide reliable performance for years to come.

Conclusion

In conclusion, car battery electroplating is a shining example of how science and technology can come together to give new life to old materials. It’s like giving your car battery a superhero suit, as it protects it from corrosion and extends its lifespan. Not only is it an economically viable option, but it also reduces waste and showcases the beauty of electrochemistry.

So, if you want to make your car battery last longer and look cooler, consider electroplating. Your car, and the environment, will thank you.”

FAQs

What is electroplating?

Electroplating is the process of coating a metal object with a thin layer of another metal using electrolysis.

What metals are commonly used in electroplating car batteries?

Lead, silver, and calcium are commonly used metals in electroplating car batteries.

How does electroplating affect the life of a car battery?

Electroplating can extend the life of a car battery by protecting the lead acid plates from corrosion.

Can a car battery be reconditioned using electroplating?

Yes, there are specialized electroplating techniques that can be used to recondition damaged or worn out car batteries.

Is electroplating a cost-effective method for car battery maintenance?

Yes, electroplating is a cost-effective method for maintaining car batteries as it prevents corrosion and extends the battery life.