Demystifying the Carbon Lifecycle of Electric Car Batteries: A Sustainable Future for Transportation

Electric cars are often hailed as the future of transportation, and for good reason. They offer a greener and cleaner alternative to traditional gasoline-powered vehicles, greatly reducing carbon emissions. However, amidst all the benefits of electric cars lies the question of the carbon lifecycle of electric car batteries.

How green are they really – from manufacturing to disposal? In this blog post, we will explore the complex journey of electric car batteries, shedding light on the carbon footprint of these innovative vehicles.

Introduction

The carbon lifecycle of an electric car battery is a critical factor in the overall environmental impact of electric vehicles. While electric cars produce zero emissions on the road, the production, transportation, and disposal of their batteries have a significant carbon footprint. The manufacturing process of an electric car battery requires a considerable amount of energy and emits greenhouse gases, primarily carbon dioxide.

The materials used in the battery production, such as lithium and cobalt, are also mined and processed, adding to the carbon footprint. However, the good news is that the lifecycle carbon emissions of an electric car battery are much lower than those of traditional fossil fuel vehicles. As the world moves towards renewable energy sources, the carbon footprint of electric car batteries will decrease, making them an even more environmentally friendly choice.

What are Electric Car Batteries?

Electric car batteries are the powerhouse of electric vehicles. These rechargeable batteries store the electric energy that fuel the electric motors in cars, providing them with the energy required to move forward. These batteries are typically made up of hundreds or thousands of small cells that are connected together.

The most common type of battery used in electric cars is the lithium-ion battery, which has a high energy density and can provide a long driving range. Other types of electric car batteries include nickel-metal hydride (NiMH) and solid-state batteries which are currently being developed. As more and more people are switching to electric cars for their eco-friendliness, the importance of electric car batteries is becoming more clear.

These batteries are the key to making electric cars a viable option for daily use, as they store the energy required to move the vehicle. They can be charged using a conventional wall socket, or at a dedicated charging station. The capacity of electric car batteries is measured in kilowatt-hours (kWh), with larger batteries providing longer ranges and faster acceleration.

Overall, electric car batteries are a crucial component of electric vehicles. They store the energy required to move the vehicle, and the development of more efficient batteries is essential to increasing the adoption of electric cars. As more research is done in this field, we can expect even better performance from electric car batteries, leading to more efficient and environmentally-friendly vehicles on our roads.

Why is Carbon Footprint Important?

“carbon footprint” Introduction: Carbon footprint refers to the total amount of greenhouse gas emissions caused by an individual, organization, or product. It is calculated by considering all activities that emit greenhouse gases, such as driving a car, heating a home, or producing a product. Carbon footprint is essential because it helps people understand the extent of their impact on the environment and the measures they can take to reduce it.

By measuring each activity’s carbon footprint, individuals, businesses, and governments can identify areas that require changes. In this way, carbon footprint calculation helps in the fight against climate change.

Manufacturing Phase

During the manufacturing phase of an electric car battery, the carbon footprint of the vehicle can have a significant impact on its overall lifecycle. The production of batteries requires the sourcing and extraction of various metals and minerals, such as nickel, cobalt, and lithium, which can have negative environmental effects. Additionally, the energy-intensive manufacturing processes involved in battery production contribute to greenhouse gas emissions.

However, efforts are being made to reduce the carbon footprint of electric car batteries by improving the efficiency of production and using more sustainable materials. For example, some manufacturers are exploring the use of alternative, less carbon-intensive materials, like recycled metals, in their production processes. Adopting circular business models and utilizing sustainable energy sources during production can also minimize the negative environmental impact of the manufacturing phase of electric car batteries.

By taking steps to reduce greenhouse gas emissions and adopt more sustainable practices, the carbon lifecycle of an electric car battery can be significantly improved.

Raw Material Extraction

Raw Material Extraction is a critical phase in the manufacturing process. This phase involves sourcing, extracting, and refining raw materials needed in the production of various products. The sourcing process can be from natural resources, including forests, mines, and oceans.

The extraction process can cause significant environmental impacts such as deforestation, water and air pollution, soil erosion, and habitat destruction. It’s essential to note that raw material extraction has a significant impact on the environment and human health, and therefore the process must be done sustainably and responsibly. Manufacturers should adopt eco-friendly mining and extraction methods that prioritize environmental conservation and human safety.

These methods include recycling, using renewable energy sources, and reducing waste during the extraction process. Adapting sustainable raw material extraction practices ensures that the manufacturing industry remains operational while safeguarding the environment for future generations.

Battery Production Process

Battery production is a multi-stage manufacturing process that involves several critical phases to ensure quality and efficiency. The process typically begins with the preparation of raw materials such as lithium, cobalt, and nickel. These materials are then processed to create a slurry that is coated onto a thin metal foil.

Next, the coated foil is dried and rolled into a cylindrical shape, creating the cathode. A similar process occurs for creating the anode, which is typically made from graphite. Once both the cathode and anode are created, they are assembled with a separator and electrolyte to create the battery cell.

The final manufacturing phase typically involves testing and quality control to ensure the battery’s performance and safety. Throughout each stage of the process, strict precautions are taken to ensure the handling and storage of materials to prevent accidents and maintain product integrity. Overall, the battery production process is highly complex and requires specialized knowledge and expertise to ensure high-quality batteries that meet rigorous industry standards.

Transportation of Battery Materials

The transportation of battery materials during the manufacturing phase is a crucial aspect of the entire process. There are different transportation methods used, such as road, rail, sea, and air, depending on the type of material and location. One of the main concerns is the safety and security of transporting lithium-ion batteries due to their flammable nature.

Therefore, special containers and packaging are used, and training is provided for the personnel handling these materials. Besides safety, there are also environmental concerns, such as emissions from transportation. To minimize these impacts, manufacturers may opt for more sustainable transportation methods and use low-emission vehicles.

Excellent communication and coordination between all parties involved, including manufacturers, transport companies, and government regulators, are essential for successful transportation of battery materials during the manufacturing phase.

Usage Phase

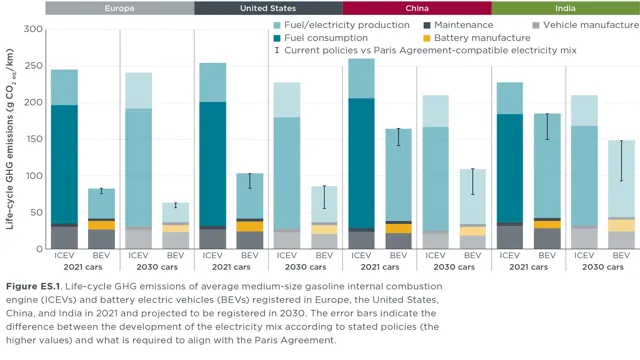

Once an electric car battery has been manufactured, it goes through a usage phase. During this phase, the battery’s carbon footprint is generated through its electricity consumption. However, while the electricity used to charge the battery may come from non-renewable sources, such as fossil fuels, the battery’s energy efficiency still makes it more environmentally friendly than a traditional gasoline-powered car.

Additionally, many governments are aiming to switch to more renewable energy sources, meaning that the electricity used to power the electric car battery will become cleaner over time. Furthermore, advancements in battery technology are also making electric vehicle batteries more efficient and reducing the amount of energy they consume, further reducing their carbon footprint. Overall, while the usage phase does contribute to the carbon lifecycle of an electric car battery, it is still more eco-friendly than traditional gas-powered cars and will only become even more environmentally friendly as time and technology advance.

Charging Methods

During the usage phase, there are different charging methods you can use to keep your device powered up. The most common method is through a wall socket, using a charger that comes with your device. This method provides the fastest charging time, making it ideal for emergency situations when you need your device up and running quickly.

Another popular method is wireless charging, which uses electromagnetic fields to transmit energy from the charging pad to your device without the need for cables. This method is convenient for everyday use, as you can simply place your device on the charging pad and let it charge while you go about your day. For those on the go, portable chargers are a useful option.

These rechargeable power banks can be charged in advance and used to charge your device while you’re away from a power source. Whatever method you choose, it’s important to follow manufacturer recommendations to ensure safe and efficient charging of your device.

Battery Efficiency and Lifespan

During the usage phase, battery efficiency and lifespan are crucial factors that directly impact user experience. The efficiency of a battery refers to the amount of power it consumes to perform a particular task. The more efficient a battery is, the longer it will last on a single charge.

To ensure maximum efficiency, it’s essential to use the device’s battery-saving mode and avoid running multiple applications simultaneously. Additionally, it’s crucial to maintain a stable temperature while using the device as extreme temperatures can lead to battery degradation. Another factor that affects battery lifespan is the frequency of charging.

Overcharging or undercharging can lead to rapid depletion of the battery capacity, which may affect its overall lifespan. It’s recommended to keep the battery level between 40-80% and avoid charging the device overnight. By following these simple tips, users can ensure maximum battery efficiency and lifespan, allowing them to get the most out of their devices.

Emissions from Electricity Generation

When it comes to emissions from electricity generation, the usage phase plays a significant role. This phase involves the consumption of electricity by households, businesses, and industries. The more electricity we use, the more emissions are produced by power plants to meet the demand.

Therefore, reducing our electricity consumption through energy-efficient practices can help lower emissions from electricity generation. This can be achieved by using LED light bulbs, turning off lights and electronics when not in use, and investing in energy-efficient appliances and equipment. Additionally, using renewable energy sources such as solar panels and wind turbines can also contribute to reducing emissions during the usage phase.

By being mindful of our electricity consumption and making small changes to our daily habits, we can make a big impact on reducing emissions from electricity generation.

End of Life Phase

The end of life phase of an electric car battery can have a significant impact on the carbon lifecycle of the battery. Once an electric car battery reaches the end of its useful life, it can be recycled or disposed of properly. Proper disposal is crucial to reducing the carbon footprint of the battery.

Recycling can be an effective way to reduce emissions and conserve valuable resources, but it is important to note that it is not a perfect solution. Recycling processes can also have environmental impacts, and not all materials can be recycled. Therefore, it is also important to continue researching and developing new solutions for sustainable battery disposal and recycling.

Additionally, extending the life of batteries through repurposing or second-life applications can also reduce the carbon footprint and help to reduce waste. Overall, the end of life phase is an important aspect to consider in the carbon lifecycle of an electric car battery.

Battery Recycling and Disposal

Battery recycling and disposal are crucial components of the end of life phase for batteries. After batteries have served their intended purpose, they can no longer hold a charge and need to be properly disposed of or recycled. Improper disposal of batteries can lead to environmental harm, as they can release toxic chemicals into the soil and water if they end up in landfills or natural bodies of water.

That’s why it’s important to recycle batteries, as they contain valuable materials that can be repurposed and reused in the manufacturing of new batteries or other products. This reduces the need for new resources to be extracted, preserving our natural resources. By properly recycling batteries, we can contribute to a cleaner environment and a more sustainable future for all.

Environmental Impact of Recycling

When it comes to recycling, many people assume that it is always the better option for the environment. However, the end of life phase of recycling can still have some negative impacts. During this phase, recycled materials are sent to a recycling facility or manufacturer to be processed into new products.

This process can lead to energy consumption, emissions, and waste. For example, transportation of the materials can result in the emission of greenhouse gases, and the process of turning old products into new ones can require a lot of energy. Additionally, not all recycled materials can be used again and may still end up in landfills.

That being said, recycling still has the potential to reduce the amount of waste that ends up in landfills and conserve natural resources. Overall, it is still important to consider the end-of-life phase of recycling and to minimize our waste production in the first place.

Conclusion

In conclusion, the carbon lifecycle of an electric car battery is a complex and constantly evolving journey. From the mining of the raw materials to the eventual disposal or recycling of the battery, each step along the way emits carbon and has the potential to impact the environment. However, the switch to electric cars and renewable energy sources provides a promising alternative to the use of fossil fuels and the resulting carbon emissions.

We may not have all the answers yet, but by continuing to innovate and prioritize sustainability, we can pave the way towards a brighter, cleaner future. As they say, it’s time to put the pedal to the metal – but let’s make sure it’s an electric one!”

FAQs

What is the carbon footprint of an electric car battery?

While electric cars produce zero emissions on the road, they do contribute carbon emissions during production and disposal of the battery, which is known as the carbon lifecycle of an electric car battery.

How does the carbon footprint of an electric car battery compare to a traditional gasoline car’s emissions?

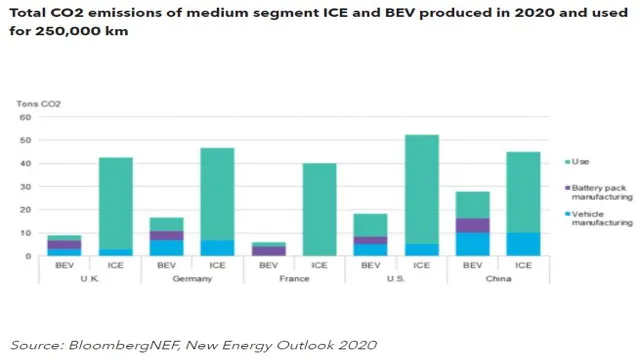

Studies have shown that over the lifetime of the vehicle, an electric car’s carbon footprint is significantly lower than that of a traditional gasoline car, even when taking into account the production and disposal emissions of the battery.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. In fact, recycling the lithium-ion batteries in electric cars can reduce the carbon footprint of the vehicle even further by reducing the need for new battery production.

What steps are being taken to reduce the carbon footprint of electric car batteries?

Researchers are working on developing new battery chemistries and production methods that can reduce the carbon emissions associated with electric car battery production. Additionally, efforts are being made to increase the amount of recycled material used in new battery production.