Cooling Your Electric Ride: The Ultimate Guide to CFD Design for Car Battery Cooling Systems

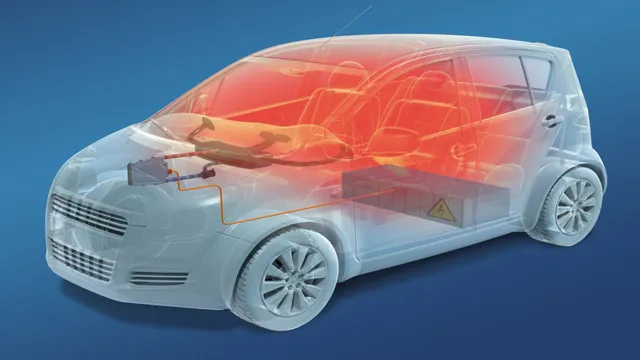

Do you know that one of the biggest challenges in the electric car industry is maintaining their battery temperature? Excessive heat can damage the battery cells, reducing efficiency and shortening the lifespan of the battery. That’s why electric car manufacturers have been striving to develop an efficient cooling system that can preserve the battery’s performance and longevity. In this blog post, we’ll delve into the world of Computational Fluid Dynamics (CFD) and how it can help design an efficient battery cooling system for electric cars.

So, sit back, relax, and join us on this journey.

Importance of Efficient Battery Cooling Systems

The efficiency of the battery cooling system in electric cars is critical to optimize the performance of the vehicle. CFD, or computational fluid dynamics, plays a crucial role in the design of efficient battery cooling systems by modeling the heat transfer and fluid flow within the system. Without adequate cooling, the battery can overheat and degrade, leading to a shorter lifespan and reduced performance.

Implementing an effective cooling system using CFD analysis can ensure that the battery operates at an ideal temperature and maintains its optimal performance. Additionally, advances in CFD technology have made it possible to design more compact and lightweight systems, which is essential in electric cars where space and weight are at a premium. Thus, an efficient battery cooling system designed with CFD technology can not only improve performance and lifespan but also contribute to reducing the weight and overall cost of the vehicle.

How it affects electric car performance

Efficient Battery Cooling Systems for Electric Cars Electric cars are gaining popularity as a more sustainable alternative to traditional gasoline-powered vehicles. However, one important factor that affects electric car performance is the battery’s temperature. Excessive heat can cause damage to the battery, which in turn can reduce its performance and longevity.

This is where efficient battery cooling systems come into play. These systems help regulate the temperature of the battery to ensure that it operates at an optimal level. If a battery is too hot, it can cause problems such as reduced range and slower charging times.

On the other hand, if a battery is too cold, it may not be able to provide enough power to the electric motor. Therefore, efficient battery cooling systems are crucial to maintaining the performance and durability of electric car batteries. With proper cooling, electric cars can deliver the range and performance that drivers expect while reducing their carbon footprint.

How it affects battery lifespan

Battery lifespan is a crucial factor to consider when it comes to phone usage. One of the most significant factors that can impact it is the efficiency of the battery cooling system. When the battery is being used, it generates heat, and excessive heat can damage the battery’s cells, reducing its overall lifespan.

Therefore, it’s essential to have an efficient cooling system that can maintain the battery’s temperature and prevent it from overheating. Besides, a proper system can enhance battery performance and ensure it remains functional for a more extended period. In simple terms, think of it as a car engine; if it overheats, it won’t operate correctly, and the same goes for your battery.

So, it’s vital to have an efficient cooling system in place to keep your phone battery healthy and long-lasting.

Understanding CFD

CFD, or Computational Fluid Dynamics, is a powerful tool used in a variety of industries, including the design of electric car battery cooling systems. Essentially, CFD simulates how fluids – like air or liquid – flow around objects. By inputting information such as the size and shape of the object, as well as factors such as temperature and pressure, CFD can accurately predict how the fluid will behave.

In the context of electric car battery cooling system design, CFD can help engineers optimize the system’s efficiency, ensuring that the battery stays at a safe temperature and functions as intended. For example, by using CFD simulations, engineers can test different cooling strategies and identify any potential hotspots in the battery that could lead to overheating. Ultimately, by utilizing CFD, designers can create more effective and reliable electric car battery cooling systems, helping to ensure the safety and longevity of electric vehicles on the road.

Explanation of CFD in car battery cooling system design

CFD (Computational Fluid Dynamics) When designing a car battery cooling system, computational fluid dynamics (CFD) is a vital tool for engineers to simulate and analyze various cooling strategies. CFD allows for the study of fluid flow, thermal behavior, and heat transfer, providing insights into the best cooling system design. This simulation software analyzes and solves complex equations of fluid dynamics to generate visualizations of the system’s performance.

Using CFD software, designers can optimize the cooling system by testing different designs, materials, and cooling strategies and evaluating the thermal behavior of the battery. CFD provides a cost-effective and efficient way to reduce the design cycle, and a proper cooling system can extend battery life and improve the performance of electric vehicles. In summary, CFD is a powerful design tool that allows engineers to optimize the cooling system for electric vehicle batteries to ensure optimal operation, improved performance, and longevity.

Tools and Software for CFD analysis

Computational Fluid Dynamics (CFD) Computational Fluid Dynamics (CFD) is a powerful tool used by engineers to simulate fluid flow in virtual environments. It uses numerical analysis and algorithms to solve fluid flow problems in complex geometries. CFD simulations are used to study a wide range of phenomena, from the flow of fluid through pipes and channels to the flow of air over aircraft wings.

The key advantage of CFD is that it provides engineers with the ability to test and optimize designs without the need for expensive physical prototyping. To perform a CFD analysis, engineers use software tools such as ANSYS Fluent, OpenFOAM, and Autodesk CFD. These tools use a variety of numerical methods to solve the Navier-Stokes equations that govern fluid flow.

Engineers can input designs into the software and subject them to different flow conditions to study their behavior and performance. CFD simulations can be used to optimize designs for improved efficiency, reduce drag, minimize pressure drop, and much more. With the help of CFD, engineers can create new and innovative designs without the need for physical testing, saving both time and money.

Factors Affecting CFD in Electric Car Battery Cooling System Design

When it comes to electric car battery cooling system design, CFD (Computational Fluid Dynamics) plays a crucial role in optimizing performance. However, there are various factors that can affect the accuracy of CFD simulations. One significant aspect is the complexity of the cooling system itself.

The more intricate the design, the more difficult it can be to accurately model the flow of air and coolant. Additionally, the condition of the battery can also impact the accuracy of CFD. If the battery is in poor condition or has damaged cells, it can affect how heat is distributed throughout the system.

Another critical factor is the thermal conductivity of the battery and cooling system materials. Suboptimal heat transfer can lead to poor cooling performance, which can cause issues such as battery degradation and reduced range. By taking these factors into account and optimizing the design accordingly, engineers can use CFD to create effective cooling systems for electric car batteries.

Thermal conductivity of battery materials

When designing a cooling system for an electric car battery, several factors affect the computational fluid dynamics (CFD) analysis. One of the most critical factors is the thermal conductivity of the battery materials. This factor determines how well the battery can dissipate heat.

Low thermal conductivity can cause the battery to overheat, leading to reduced efficiency and even damage. Therefore, it is crucial to choose battery materials with high thermal conductivity to ensure effective cooling. Additionally, other factors such as the cooling fluid’s flow rate, the design of the cooling system, and the battery’s operating temperature also affect the CFD analysis.

By considering all of these factors, engineers can design an efficient and reliable cooling system that ensures optimal battery performance and longevity.

Fluid flow characteristics

CFD, electric car battery cooling system design The use of Computational Fluid Dynamics (CFD) in the design of electric car battery cooling systems has become increasingly popular due to its accuracy and efficiency. However, certain factors can affect CFD simulations and ultimately impact the design of the cooling system. One of the most crucial factors is the fluid flow characteristics, such as the flow rate, viscosity, and turbulence of the coolant fluid.

These characteristics can significantly influence the cooling performance and efficiency of the system. Moreover, the location and shape of components like the battery pack and heat exchangers can affect the fluid flow and convective heat transfer, potentially leading to inefficient cooling or hotspots in the battery. Therefore, accurate modeling of the fluid dynamics is imperative in designing an effective and reliable electric car battery cooling system.

By considering these factors, engineers and designers can create efficient and robust cooling systems that can maintain optimal battery temperature and prolong battery life.

Steps to Design Efficient CFD

Designing an efficient CFD (Computational Fluid Dynamics) for electric car battery cooling system is crucial when trying to optimize the performance of these vehicles. To do this, the first step is to establish the specific objectives of the project. The objectives could be to reduce the energy consumption of the cooling system, to increase battery lifespan, or to improve the thermal dissipation of the cooling system.

Once the objectives are clear, the next step is to gather relevant data on the system. This includes geometrical data, operating conditions, and material properties. With all the required data, the next step is to create a CFD model.

While creating the model, it’s essential to ensure that the model is as accurate as possible. This means including all the relevant physical phenomena such as thermal radiation, heat transfer, and fluid flow. Once the CFD model is created, it’s time to validate the model by comparing the results with experimental data.

This helps ensure that the model accurately represents the real-world system and is useful for making decisions. By following these steps, it’s possible to design an efficient CFD for electric car battery cooling system and get the best out of these vehicles.

Analyzing system requirements

When it comes to designing efficient CFD, analyzing system requirements is a crucial step. Before diving into the technicalities, it’s important to understand the client’s needs and goals for the project. This can involve talking to the client, observing existing systems, and researching industry best practices.

Once requirements are established, the next step is to gather data that is relevant to the problem at hand. This may involve acquiring 3D models, CAD drawings or other relevant information. With the data in hand, it’s then possible to start building the CFD model.

Overall, the goal is to design a CFD system that’s tailored to meet the client’s needs while providing accurate and efficient performance. By taking the time to understand the client’s goals, and gathering the right data, it’s possible to build a CFD system that’s efficient, accurate, and cost-effective.

Creating a virtual model

Creating a virtual model is an essential step towards designing efficient CFD. It involves building a digital replica of the system under analysis, including all of its components and structures. This step helps engineers get a comprehensive understanding of the system and identify potential issues that may come up during the simulation.

To create an accurate virtual model, engineers use specialized software that employs methods like 2D/3D meshing, surface modelling, and solid modelling, among others. The software also assists in setting up the boundary and initial conditions of the simulation. One critical aspect to consider when creating a virtual model is the level of detail required.

Including too many details can increase the computational cost and can lead to a more extended simulation time. Conversely, lacking certain details can lead to inaccuracies in the results. Therefore, it is essential to strike a balance between detail and efficiency, specific to the system under examination.

Performing simulations and optimizations

Designing Efficient CFD When it comes to performing simulations and optimizations, there are a few key steps to keep in mind when designing efficient CFD (Computational Fluid Dynamics). Firstly, it’s important to clearly define the problem you’re trying to solve and the goals you want to achieve. This will help guide your decisions throughout the design process.

Next, you’ll need to carefully select the appropriate equations, models, and numerical methods for your specific situation. You’ll also need to consider factors like the mesh resolution and boundary conditions. Once your simulation is set up, it’s critical to ensure accurate and reliable results through validation and verification processes.

Finally, it’s always a good idea to continually evaluate and optimize your simulation as necessary to ensure it’s meeting your goals and providing the insights you need. By following these steps, you can design an efficient CFD that delivers the accuracy and insights you need to succeed.

Conclusion

In conclusion, using CFD for electric car battery cooling system design is like having a superhero on your side. With its ability to simulate and analyze the flow of heat and fluid, CFD can help engineers design a cooling system that’s both efficient and effective. So if you’re looking to keep your battery from overheating, look no further than the power of CFD!”

FAQs

How does CFD help in designing an electric car battery cooling system?

CFD simulations allow engineers to analyze the flow and heat transfer within the battery cooling system, optimizing its design for improved performance and efficiency.

What are some common challenges in designing a CFD model for an electric car battery cooling system?

Some challenges include accurately modeling the complex geometry of the battery cells, dealing with non-uniform flow and heat transfer, and selecting appropriate boundary conditions and turbulence models.

How can CFD simulations aid in predicting the thermal behavior of an electric car battery during operation?

By simulating the temperature distribution within the battery pack, engineers can predict hotspots and thermal runaway events, ensuring safe and efficient operation of the battery system.

What factors should be considered when selecting the coolant for an electric car battery cooling system?

Factors such as thermal conductivity, viscosity, cost, and environmental impact should be considered when selecting a coolant for an electric car battery cooling system. Additionally, the coolant should be non-conductive and chemically compatible with the battery materials.