Revving Up Your Electric Ride: Unlocking the Power of Commodities for Optimal Battery Performance

Electric cars have received a lot of attention in the past decade, with more and more people opting for these eco-friendly vehicles. However, have you ever stopped to think about the components that make these cars run? One of the most crucial elements of electric vehicles is their battery, which powers the car and provides it with the energy to travel long distances. Have you ever wondered what commodities are used to make these batteries? In this blog, we will explore the commodities for electric car batteries, their importance, and how they are sourced.

Discovering the answer will undoubtedly astound you.

What are Electric Car Batteries?

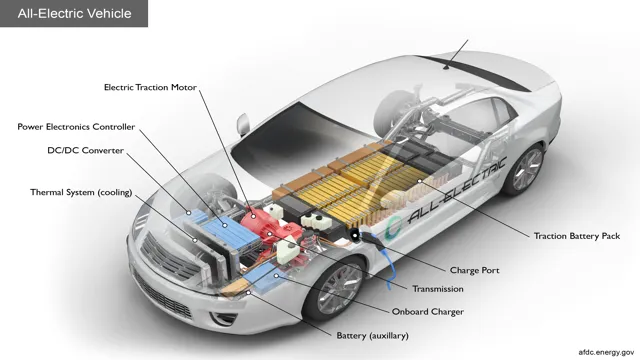

Commodities for electric car batteries are the essential components that store energy and power the vehicle’s motor. Lithium-ion batteries are the most common type used for electric cars, and they consist of several key materials, including lithium, cobalt, nickel, and manganese. Lithium is the critical component that allows the battery to store and release energy efficiently.

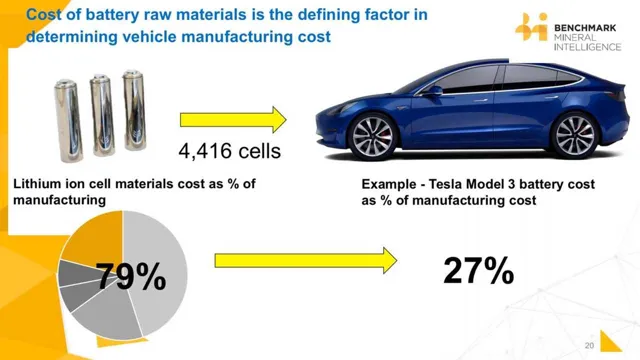

Cobalt enhances the battery’s lifespan and thermal stability, while nickel and manganese work together to improve the battery’s performance and reduce costs. These materials are scarce and costly to mine, which is why the production of electric car batteries is expensive. However, with the rise in demand for electric vehicles, advancements in technology, and increased recycling efforts, the cost of these commodities may decrease in the future, making electric cars more affordable and accessible to the general public.

Composition of Electric Car Batteries

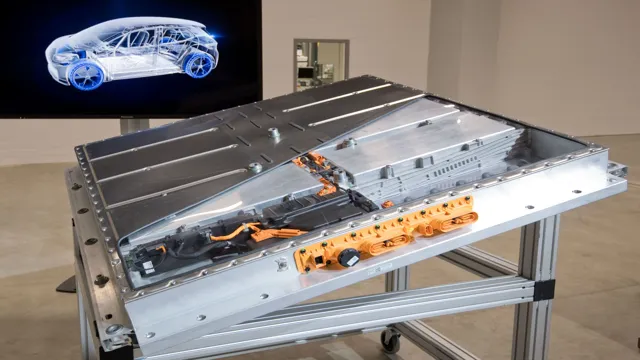

Electric car batteries are the heart of any electric vehicle. They make it possible for electric cars to run effectively, providing power to the electric motor and achieving impressive speeds. But what exactly are electric car batteries composed of? There are a variety of battery types available to power electric vehicles, but the most commonly used are lithium-ion batteries.

These are similar to the batteries used in smartphones and laptops, but much larger and more powerful. Inside these batteries, you’ll find various components, including a number of cells that store the energy. The cells are made up of electrodes, a separator, and an electrolyte.

The anode is typically made of graphite, while the cathode is made from a metal oxide. When the battery is charged, lithium ions move from the cathode to the anode, and when it’s discharged, they move back again. The separator keeps the lithium ions from interacting with one another, while the electrolyte allows them to travel between the electrodes.

Overall, this sophisticated system of components and materials is what makes it possible for electric cars to travel for miles on end.

Different Types of Electric Car Batteries

Electric car batteries are the lifeblood of electric vehicles. They provide the necessary energy to power the car’s motor and keep it running. Because of their importance, there are many different types of electric car batteries available on the market today.

The most common type of electric car battery is the lithium-ion battery. This type of battery is lightweight and has a high energy density, which allows it to store a lot of energy in a small space. Another popular type of electric car battery is the nickel-metal hydride battery.

This type of battery is more environmentally friendly than lithium-ion batteries and has been used in hybrid vehicles for many years. Other types of electric car batteries include lead-acid batteries and solid-state batteries. Each type of battery has its own advantages and disadvantages, and the choice of which battery to use will depend on the specific needs of the vehicle and driver.

Commodities Used in Electric Car Batteries

Electric cars are becoming more and more popular these days and for good reason. Not only are they environmentally friendly, but they’re also jam-packed with technology that makes driving them a breeze. But have you ever wondered what goes into making an electric car battery? There are several commodities used for electric car batteries, with the most notable being lithium, cobalt, nickel, and graphite.

Lithium is the most essential of these commodities, as it’s used to make the cathode – an essential component that stores energy in the battery. Cobalt is also essential for battery production, though it’s not as abundant as lithium. Nickel, on the other hand, is used to enhance the energy density of the battery while graphite is used to make the anode.

Overall, each of these commodities plays a key role in making a battery that’s powerful, efficient, and long-lasting.

Lithium – The Most Essential Commodity

Lithium is currently the most essential commodity for the production of electric car batteries. With the rise of electric vehicles, the demand for lithium has increased significantly over the years. Lithium is a lightweight, highly reactive metal that is essential for creating the high-energy batteries that power electric cars.

It is primarily found in underground brine reserves, making it a scarce resource that is challenging to mine and extract. However, its properties make it a highly sought-after commodity, and lithium prices have been steadily increasing in recent years. Other commodities used in electric car batteries include cobalt, nickel, and manganese.

These metals are also in high demand due to their use in battery production. As the world transitions towards renewable energy, the demand for these commodities will only continue to rise, making it more important than ever to find sustainable ways to mine and extract them.

Cobalt – A Crucial Ingredient in Battery Production

Cobalt is a crucial commodity used in the production of electric car batteries. It is essential in the creation of the cathode, which stores the energy that powers the vehicle. Cobalt is a relatively rare and expensive metal, which has led manufacturers to search for alternatives.

However, as of now, it remains a crucial part of the battery-making process. Its scarcity makes it a valuable investment, and many companies have invested in cobalt mines in countries like the Democratic Republic of Congo, which holds almost 68% of the world’s reserves. Companies like Tesla and Apple are also working towards reducing the amount of cobalt needed in their batteries, making them more sustainable and cost-effective.

While cobalt is just one of the many commodities used in electric car batteries, its significance cannot be overstated, and its price will continue to have a significant impact on the electric car market.

Nickel – A Metal in High Demand

Nickel is becoming increasingly valuable as demand for electric car batteries surges. As more and more consumers turn to eco-friendly transportation alternatives, the need for efficient batteries with a high energy density is paramount. Nickel offers just that – it can store a large amount of energy in a relatively small amount of space.

This makes it an ideal metal for rechargeable batteries, and experts predict that nickel demand will continue to rise in the coming years. As a result, nickel mining and production are likely to increase as well. However, the surge in demand for nickel has environmentalists concerned about the impact that increased mining will have on the planet.

Despite this, the electric car industry shows no signs of slowing down, and nickel will continue to be a key component of the batteries that power these eco-friendly vehicles.

Future of Commodities for Electric Car Batteries

The demand for commodities used in electric car batteries is on the rise. Lithium, cobalt, manganese, and nickel are crucial for producing high-quality rechargeable batteries that power electric cars. However, with the booming electric car market, the supply of these commodities may not be able to keep up with the demand.

This could lead to price volatility and supply chain disruptions. To mitigate these risks, some companies are exploring alternative materials and innovative production methods that could reduce the reliance on these commodities while still producing efficient batteries. For instance, researchers are investigating the use of sodium-based batteries that don’t require lithium, and solid-state batteries that rely less on cobalt.

There are also efforts to improve recycle-ability and reuse of these materials. Ultimately, the future of commodities for electric car batteries is uncertain, but with innovation and sustainable practices, we can mitigate the risks and ensure a steady supply of these essential materials.

Potential Shortages and Solutions

As electric vehicles become more popular, the demand for the commodities needed for their batteries will increase. Some experts predict that we may see potential shortages of certain metals such as lithium, cobalt, and nickel. These materials are essential for producing the high-performance batteries that power electric cars.

However, there are solutions being developed to address these potential shortages. One solution is to use alternative materials such as magnesium, aluminum, and zinc. Other strategies include recycling and improving the efficiency of battery production processes.

As the electric car industry continues to grow and evolve, it’s important to consider these potential challenges and work towards sustainable solutions. By investing in research and development, we can ensure that the future of electric vehicles is both environmentally friendly and economically feasible.

Emerging Commodities in Battery Production

As we move towards a future with electric vehicles dominating the roads, the demand for battery production is increasing exponentially. This has led to the emergence of new commodities that will be vital in the production of these batteries. Lithium, the classic battery ingredient, is facing increasing competition from emerging commodities such as cobalt, nickel, and manganese.

These metals are being used more often due to their increased efficiency in storing energy and longevity. However, with the rise of these new metals, there are concerns about their availability and extraction methods. The industry needs to ensure that the supply of these emerging commodities is sustainable and ethical.

Overall, it’s exciting to see the growth of these new commodities and how they will shape the future of electric car batteries.

Conclusion: The Importance of these Commodities

When it comes to commodities for electric car batteries, it’s clear that demand is high and the potential for growth is limitless. With lithium, cobalt, nickel, and graphite leading the pack, it’s an exciting time for the mining industry and a promising time for the future of transportation. As we continue to prioritize sustainable and innovative solutions, it’s safe to say that the commodities powering our electric cars will only become more valuable and crucial in the years to come.

“

FAQs

1. What kind of commodities are essential for electric car batteries? A: The essential commodities for electric car batteries are lithium, nickel, cobalt, and manganese. 2. Which commodity is the most critical for electric car batteries? A: Lithium is the most critical commodity required for manufacturing electric car batteries. 3. What is the current worldwide demand for commodities used in electric car batteries? A: The current worldwide demand for lithium, cobalt, nickel, and manganese used in electric car batteries is growing exponentially and is projected to increase significantly in the coming years. 4. Are there any alternative commodities that can replace the essential ones required for making electric car batteries? A: There are efforts to use alternative technologies and commodities such as solid-state batteries and sodium-ion batteries, but the current technology requires lithium, nickel, cobalt, and manganese to produce efficient and high-performing electric car batteries.