Powering the Future: Discovering the Essential Components of an Electric Car Battery

Electric cars have been around since the early 20th century, but their popularity has picked up pace in recent years as awareness of eco-friendly cars has surged. One of the key components that separates electric cars from the rest of the pack is their battery. Electric car batteries are designed to provide power to the motor that runs the car.

However, the current for the motor comes from various battery components working together in harmony. Exploring the components of an electric car battery provides a glimpse into the technology that propels this kind of car and why it’s vital to keep these components in top condition.

Battery cells

When it comes to electric cars, the battery is the main source of power and is made up of several components. The most important component of an electric car battery is the battery cells. These cells are what actually store the electrical energy needed to power the car.

Electric car batteries typically contain thousands of individual battery cells that are connected in a complex series and parallel arrangement. Each cell generates a certain voltage, and by connecting them in a specific pattern, the total voltage of the battery can be increased or decreased. The type of battery cells used in electric cars can vary, but the most common types are lithium-ion and nickel-metal hydride.

Lithium-ion batteries are generally more expensive but offer better performance and a longer overall lifespan, while nickel-metal hydride batteries are less expensive but have a shorter lifespan and lower performance. Overall, the battery cells are a critical component of any electric car battery, and their quality and performance can have a significant impact on the overall efficiency and range of the vehicle.

Lithium-ion

Lithium-ion battery cells are the powerhouses behind most of our modern-day electronic devices. These cells utilize the chemical reaction between lithium ions and a conductive electrolyte to generate electrical energy. What makes these battery cells so popular is their high energy density, which allows for extended battery life without adding extra weight to the device.

They are also rechargeable, making them an eco-friendly and cost-effective choice. Despite their advantages, lithium-ion battery cells are not without their drawbacks. They are highly sensitive to temperature and can be prone to thermal runaway, which can cause overheating and even explosions.

To avoid these issues, it’s important to handle and store these battery cells properly, following the manufacturer’s instructions. Overall, lithium-ion holds great promise for the future of portable battery-powered devices, and as technology continues to advance, we can expect to see them become even more efficient and ubiquitous.

Nickel-metal hydride

Nickel-metal hydride (NiMH) batteries are a common type of rechargeable battery cell that has been developed as an alternative to traditional nickel-cadmium (NiCd) batteries. NiMH cells use hydrogen-absorbing alloys as a negative electrode instead of cadmium, making them more environmentally friendly. They are commonly used in devices like cordless power tools, toys, and digital cameras because they have a higher energy density than NiCd batteries and don’t suffer from the so-called “memory effect.

” This means that they can be recharged at any time without being fully discharged first, unlike NiCd batteries, which can lose their ability to hold a full charge if they are not fully discharged before being recharged again. The disadvantage of NiMH batteries is that they have a higher self-discharge rate than other rechargeable batteries like lithium-ion (Li-ion) batteries. This means that they lose their charge over time even if they are not being used.

Battery management system

An electric car battery is composed of several components that work together to provide power for the vehicle. One of the most important components of an electric car battery is the Battery Management System (BMS). The BMS plays a crucial role in ensuring that the battery operates safely and efficiently.

It monitors the charge level of the battery, controls the temperature of the battery cells, and ensures that each cell is operating within its safe operating range. Additionally, the BMS helps to prevent overcharging or undercharging of the battery, which can reduce the lifespan of the battery or even cause it to malfunction. Overall, the BMS is an essential component of an electric car battery as it helps to ensure that the vehicle operates smoothly and safely.

Controls charging and discharging

A battery management system, also known as a BMS, is a crucial component in ensuring the longevity and performance of a battery. Essentially, the BMS functions by controlling both the charging and discharging of the battery, ensuring that it operates within its optimal parameters. This ensures the battery remains healthy and doesn’t become overcharged, which can lead to degradation and potential damage.

Additionally, the BMS helps to avoid undercharging, preventing the battery from discharging too much, which can also result in damage. Essentially, the BMS acts as a gatekeeper, monitoring and regulating the flow of energy both in and out of the battery, ensuring it operates at peak efficiency. In summary, the BMS can be likened to a traffic controller at a busy intersection – directing the flow of energy, avoiding collisions and ensuring everything runs smoothly.

Prevents overcharging, over-discharging, and overheating

Battery management systems are essential components that help prolong the lifespan and improve the safety of batteries in various types of devices. They are responsible for preventing overcharging, over-discharging, and overheating, which are some of the major causes of battery failure. Overcharging can cause the battery to lose its capacity over time, while over-discharging can cause irreversible damage to the battery.

Overheating, on the other hand, can not only damage the battery but also pose a safety hazard, especially in devices that are prone to catching fire. That’s why most modern batteries come with built-in management systems that regulate the charging and discharging processes to prevent such issues. These systems use advanced algorithms to ensure that the battery is charged optimally without causing any damage.

They are also designed to monitor the battery temperature and limit its charging rate or shut off the charging altogether if it gets too hot. As a result, battery management systems play a crucial role in ensuring the safety and performance of batteries in all types of devices, from smartphones and laptops to electric vehicles and renewable energy systems.

Battery pack

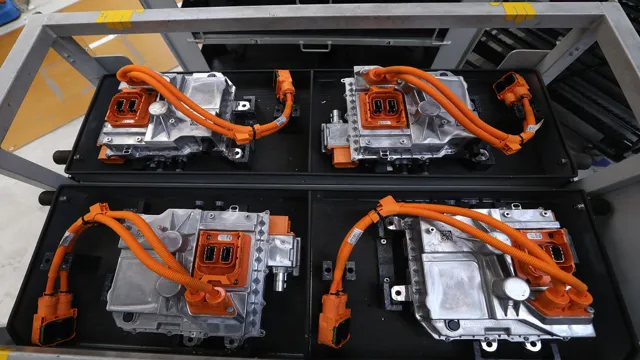

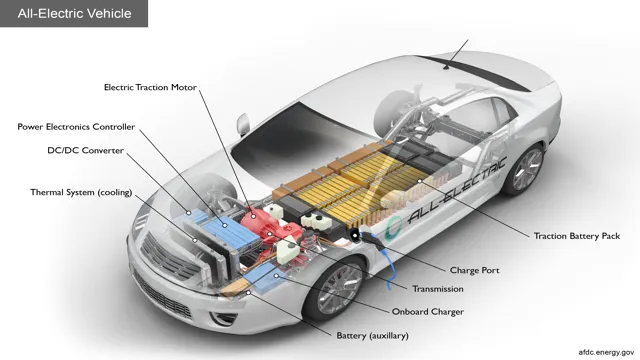

When you think about an electric car, the first thing that comes to mind is the battery pack. It’s the heart of the vehicle that powers the electric motor. There are several components that make up an electric car battery, including the cells, modules, and cooling system.

The cells are the individual units that store the electric charge. These cells are stacked together to form a module, and multiple modules are combined to create a full battery pack. The cooling system is essential to maintain the battery’s temperature, as it can overheat if it’s not managed correctly.

The battery pack is a complex system that requires sophisticated technology and engineering know-how. It’s what separates electric vehicles from traditional gas-powered cars and remains one of the most significant obstacles to overcome in the industry. However, with continued research, development, and innovation, the electric car battery is improving all the time, making electric vehicles more powerful, efficient, and affordable for the mainstream market.

Contains and protects battery cells and management system

The battery pack is an essential component of any electric vehicle. It contains and protects the battery cells and management system, ensuring their longevity and reliability. Without a properly functioning battery pack, an EV won’t be able to go very far.

So, what exactly is a battery pack? It’s a collection of individual battery cells connected together to create a larger unit. Think of it like a stack of pancakes. The battery cells are the individual pancakes, and the battery pack is the stack.

But unlike pancakes, the battery cells are high-tech pieces of equipment that store energy. The battery management system, which is integrated into the pack, ensures that each cell is charged and discharged properly, preventing overcharging or overheating. The battery pack is typically located in the floor of the EV, providing a low center of gravity for improved handling and stability.

So next time you’re driving your electric car, you can thank the battery pack for making it all possible.

Connects to electric motor for power

The battery pack is an essential component that connects to the electric motor for power in an electric vehicle. It serves as the energy storage unit that propels the vehicle forward. The battery pack is made up of several battery cells, typically lithium-ion, that work together to generate electricity.

The capacity and performance of the battery pack depend on the number of cells and the chemistry used. The battery management system regulates the flow of energy to and from the battery pack, ensuring it’s safe, efficient, and reliable. The battery pack’s size and weight can impact the vehicle’s range and handling, making it important to find the right balance.

Advances in battery technology have made electric vehicles more practical and affordable, and the demand for them is growing. Choosing a car with a robust and reliable battery pack is crucial, and manufacturers are focusing on developing high-capacity, fast-charging, and long-lasting battery packs.

Auxiliary components

When it comes to the components of an electric car battery, there are several auxiliary elements that work together to ensure the battery runs efficiently. One key component is the battery management system (BMS), which is responsible for monitoring and regulating the battery’s voltage, temperature, and state of charge. The BMS also protects the battery from damage by preventing overcharging and discharging.

Another important element is the cooling system, which helps regulate the battery’s temperature and prevent overheating. This is critical because high temperatures can reduce the battery’s performance and lifespan. Finally, the inverter, which converts the direct current (DC) from the battery into alternating current (AC) that powers the car’s electric motor, is also a crucial component.

All of these elements must work together seamlessly to keep an electric car running smoothly and efficiently.

Cooling and heating system

When thinking about cooling and heating systems, it’s important to consider the auxiliary components that make them work efficiently. One essential component is the thermostat, which regulates the temperature to ensure the system does not overwork itself. Another important component is the air filter, which filters out dust and other contaminants to maintain air quality and prevent damage to the system.

Ductwork is also a critical component, as it distributes hot and cold air throughout your home or building. Proper insulation is also important to prevent heat loss and improve energy efficiency. It’s important to regularly maintain and replace these auxiliary components to ensure the system functions optimally.

Overall, the combination of these components ensures that your cooling and heating system is not only comfortable but also efficient and cost-effective.

Voltage converter

When it comes to converting voltage, auxiliary components play an important role in ensuring a smooth and efficient operation. One such component is the transformer, which can step up or step down voltage to match the specific needs of a circuit. Another important auxiliary is the voltage regulator, which maintains a constant voltage output even when the input voltage fluctuates.

This is crucial in protecting sensitive components from damage caused by voltage spikes or drops. In addition to these, capacitors, diodes, and resistors are also commonly used in voltage converter circuits to filter, rectify, and regulate the voltage. By using the right combination of these auxiliary components, engineers can design voltage converters that are reliable, efficient, and tailored to the specific needs of their applications.

So whether you are designing a power supply for a consumer electronics device or an industrial control system, investing in quality auxiliary components can help you achieve the desired performance and longevity of your circuit.

Safety mechanisms

When it comes to safety mechanisms, auxiliary components play a key role in ensuring the protection of both operators and equipment. One such component is the emergency stop button. This button is typically located within easy reach of the operator and is designed to immediately halt all machine operations in case of an emergency.

Another important safety feature is the safety barrier. These barriers are used to cordon off certain areas of the facility to prevent unauthorized access. They are typically made from high-strength materials and are designed to withstand significant force and impact.

Additionally, sensors and limit switches are utilized to detect potential hazards such as excessive pressure or motion, and immediately stop operations in order to prevent accidents. By utilizing these and other auxiliary safety components, businesses can ensure a safe and productive work environment for all.

Conclusion

In conclusion, an electric car battery can be broken down into three key components – the anode, the cathode, and the electrolyte. Think of it like a classic love triangle where the anode and cathode are the star-crossed lovers, fueled by the energy and chemistry provided by the electrolyte. Together, they power our electric cars, reminding us that sometimes the greatest innovation can come from the simplest of partnerships.

Now, if only we could figure out how to make the battery last forever…

but hey, we can dream, can’t we?”

FAQs

What are the components of an electric car battery?

The components of an electric car battery include cathode, anode, separator, electrolyte, and casing.

How does the cathode work in an electric car battery?

The cathode in an electric car battery works by releasing electrons when connected to an external circuit, which creates a flow of electricity.

What is the role of the separator in an electric car battery?

The separator in an electric car battery separates the anode and cathode to prevent a short circuit.

What type of electrolyte is commonly used in electric car batteries?

The most common electrolyte used in electric car batteries is a lithium-ion electrolyte, which allows for high energy density and longer driving ranges.

How does the casing in an electric car battery protect the internal components?

The casing in an electric car battery protects the internal components from damage, leakage, and electrical shorts. It is usually made of a sturdy and durable material, such as aluminum or plastic.