The Power Within: Unveiling the Key Components of Electric Car Batteries

Electric cars are quickly becoming a popular mode of transportation due to their environmental friendliness and fuel efficiency. One important aspect of electric cars is their batteries, which power the vehicle and determine its overall performance. But have you ever wondered what components make up an electric car battery? In this blog, we’ll explore the different parts that work together to create the power source for your electric car.

From the cells themselves to the cooling system, we’ll break down the fascinating inner workings of these remarkable batteries. So buckle up and join us as we take a deep dive into the components of electric car batteries.

Battery Chemistry

When it comes to understanding the complex components of batteries for electric cars, one of the key factors to consider is the battery chemistry. Essentially, this refers to the specific materials and processes that are used to create the battery, which directly impact its performance and overall capabilities. For example, most modern electric car batteries utilize a lithium-ion chemistry, which is known for being lightweight, high-performing, and long-lasting.

However, there are other chemistries to consider as well, including lead-acid, nickel-metal hydride, and more. Each chemistry has its own unique strengths and weaknesses, which means that different electric car manufacturers may opt for different approaches depending on their goals and priorities. Ultimately, by understanding the intricacies of battery chemistry, consumers and industry insiders alike can gain a better appreciation for the amazing power and potential of modern electric cars.

Lithium-Ion Batteries

Lithium-ion batteries are a popular choice for powering electronic devices due to their high energy density and long lifespan. These batteries use a chemical reaction to store and release electrical energy. The most common chemistry used in lithium-ion batteries is lithium cobalt oxide, which provides high energy density but can be unstable and prone to overheating.

Other chemistries, such as lithium iron phosphate and lithium manganese oxide, offer improved stability and safety, but at the cost of slightly lower energy density. The choice of chemistry depends on the application and desired performance characteristics. It’s important to understand the chemistry of lithium-ion batteries when selecting a device or battery pack to ensure the best performance and safety for your needs.

Nickel-Metal Hydride Batteries

Nickel-Metal Hydride batteries, also known as NiMH batteries, are a popular rechargeable battery chemistry that is commonly used in consumer electronics and electric vehicles. These batteries are similar to traditional nickel-cadmium batteries, but they use a different type of cathode material, which is made from a metal hydride compound. One major advantage of NiMH batteries over their nickel-cadmium counterparts is that they are less harmful to the environment because they do not contain toxic cadmium.

NiMH batteries also have higher energy densities and can hold a charge for longer periods of time, making them a popular choice for devices that require high energy and longer run times. With advances in technology, NiMH batteries continue to improve in performance and durability, making them an attractive option for many applications.

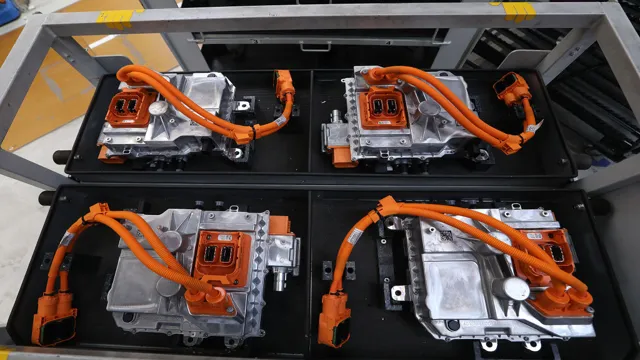

Battery Pack Design

When it comes to designing batteries for electric cars, there are a number of key components to consider. The most important is arguably the battery pack itself, which is made up of numerous individual cells that work together to provide the necessary power to propel the car. Within each individual cell, there are also a number of important components, including the electrodes, which are responsible for transmitting the electric charge, and the electrolyte, which helps to facilitate the transfer of ions between the electrodes.

Other components that may be included in the battery pack design include protective coatings, thermal management systems, and safety features such as overcharge and over-discharge protection. All of these elements play a critical role in ensuring that electric car batteries are reliable, efficient, and safe to use. As the demand for electric cars continues to grow, battery manufacturers are investing heavily in research and development to further improve the technology and make it even more accessible to consumers.

Modular vs Non-modular Designs

When it comes to designing battery packs, there are two main types of approaches: modular and non-modular designs. Modular battery pack designs offer more flexibility in terms of customization and repairs, as each module can be easily replaced or upgraded without affecting the entire system. On the other hand, non-modular designs are typically more cost-effective and simpler to manufacture, but may be less adaptable over time.

The choice between modular and non-modular designs ultimately depends on the specific needs and priorities of the application at hand. For example, if the battery pack is being used for a product that may need to adapt to changing technology or customer demands, a modular design may be a better fit. However, if cost is a major concern and the system is not likely to require major modifications, a non-modular approach may be the more practical choice.

Ultimately, the key is to carefully consider factors such as flexibility, cost, and ease of maintenance to determine which design will best support your goals.

Active vs Passive Cooling Systems

Battery Pack Design When it comes to designing a battery pack, one of the key considerations is the cooling system. There are two types of cooling systems: active and passive. Active cooling systems use fans or pumps to circulate air or a liquid coolant to prevent the battery from overheating.

On the other hand, passive cooling systems rely on the natural flow of air or materials such as heat sinks to dissipate heat. Choosing the right cooling system depends on the application and the battery’s specific needs. Passive cooling may be suitable for low-power applications, while active cooling is required for high-power applications, such as electric vehicles or data centers.

The type of cooling system can also affect the battery’s lifespan and safety. Overall, battery pack design involves a complex interplay between various factors such as cooling, capacity, voltage, and safety. By choosing the right cooling system and optimizing the overall design, battery packs can deliver optimal performance and longevity for a wide range of applications.

Cell Balancing Techniques

Cell balancing techniques are crucial for ensuring the longevity and safety of battery packs. When designing a battery pack, it’s important to ensure that all individual cells are similarly charged to prevent overcharging or undercharging. This is where cell balancing techniques come into play.

One common method involves using a balancer circuit, which monitors each cell’s voltage and redistributes the charge among them to maintain balance. Another technique is active cell balancing, which is a more sophisticated method of balancing cells. Here, the battery management system (BMS) uses feedback from cell measurements to direct current away from the cells with higher voltage and towards those with lower voltage, effectively balancing their charges.

Ultimately, a well-designed battery pack with a reliable cell balancing system can improve the performance and longevity of the battery. This is especially crucial for high-capacity battery packs used in electric vehicles and other critical applications. A poorly designed battery pack could lead to hazardous situations, so it’s important to invest in the proper techniques for cell balancing to ensure the best possible outcomes.

Battery Management Systems

When it comes to creating batteries for electric cars, careful attention is given to the components used in their construction. One critical aspect of these components is the Battery Management System (BMS). The BMS is responsible for providing essential information such as the state of charge and the health of the battery.

This information is vital for the optimization of the battery’s performance and longevity. The BMS also plays a crucial role in protecting the battery from overcharging and over-discharging, which can be a significant safety hazard. Components, such as temperature sensors and current sensors, are integrated into the BMS, ensuring that the battery operates within safe limits.

Even small deviations from these limits can significantly impact the battery’s performance, resulting in the need for expensive repairs or battery replacement. With electric cars becoming more common on the roads, it’s essential to have a reliable and safe battery management system, making it a critical component of batteries for electric cars.

State of Charge and Health Monitoring

Battery Management Systems When it comes to electric vehicles (EVs), Battery Management Systems (BMS) play a crucial role in monitoring the state of charge and health of the battery pack. A BMS not only measures the state of charge, but also ensures the battery pack is kept within safe operating limits to prevent damage or failure. The BMS constantly communicates with the vehicle’s control system to optimize charging and discharging, as well as provide vital information to the driver about the battery’s health and remaining range.

Think of the BMS as the “brain” of the EV’s battery pack, always monitoring and regulating to ensure peak performance and longevity. Without a proper BMS, an EV’s battery pack could suffer from overcharging, undercharging, or even thermal runaway – a dangerous condition where the battery overheats and can catch fire. So, it’s clear that a reliable BMS is critical to the success of any EV.

Overcharging and Overheating Protections

Battery Management System One of the critical functions of a battery management system is to prevent overcharging and overheating. These protections are essential for the safety and long-term health of batteries. Overcharging can cause a chemical reaction within the battery that leads to the release of gas, which puts pressure on the internal structure of the battery and can cause it to burst.

Overheating can also lead to an explosion or a fire. A battery management system monitors the voltage and temperature of the battery and limits the charging current accordingly to prevent overcharging and overheating. It also ensures that the battery is charged to its optimum level without damaging it.

Overall, a battery management system is a crucial component in extending the life of batteries and ensuring their safe operation.

Future of Electric Car Batteries

When it comes to electric cars, the battery is the heart of the vehicle. Without it, the car simply wouldn’t be able to move. The components of batteries for electric cars have come a long way in recent years, and continue to evolve as the demand for electric cars increases.

The three main components of an electric car battery are the cathode, anode, and electrolyte. The cathode and anode are made up of various materials, such as cobalt, nickel, and manganese. These materials determine the performance and capacity of the battery.

The electrolyte is responsible for carrying the ions between the cathode and anode. In order to improve the components of batteries for electric cars, researchers are working on developing new materials that are more efficient and sustainable. For example, some researchers are working on replacing cobalt with more abundant and cheaper materials, while others are using different types of electrolytes, such as solid-state electrolytes, to improve performance and safety.

As technology advances, we can expect to see even more exciting developments in the components of batteries for electric cars.

Conclusion

In summary, batteries for electric cars are like a superhero team, with each component playing a crucial role in powering the vehicle. The anode acts as the sturdy foundation, the cathode serves as the dynamic leader, the electrolyte acts as the wise mentor, and the separator works as the reliable sidekick. Together, they power electric vehicles to save the day (and the environment)!”

FAQs

What are the main components of batteries used in electric cars?

The main components of batteries used in electric cars include electrode, separator, electrolyte, casing, and current collector.

What is the role of the electrode in the batteries of electric cars?

The electrode in the batteries of electric cars is responsible for storing and releasing electrical energy during the charging and discharging process.

How does the separator help in the functioning of batteries for electric cars?

The separator helps in preventing the internal short circuit within the battery and allows only ions to pass through it during the charging and discharging process.

What is the function of the electrolyte in batteries of electric cars?

The electrolyte in the batteries of electric cars helps in conducting ions between the electrodes during the charging and discharging process, which generates electrical energy.

How does the current collector assist in the functioning of batteries for electric cars?

The current collector helps in collecting and transferring the electrical energy generated by the electrode to the outside circuit to power the electric car.