The Shocking Truth About the Cost of Lithium-ion Batteries for Electric Cars

As electric cars grow in popularity, one of the crucial components that enable their power and range is the lithium-ion battery. However, the cost of these batteries is often a source of concern for both car manufacturers and potential buyers. In this blog post, we will explore the cost of lithium-ion batteries for electric cars, why they are expensive, and how prices are expected to change in the near future.

Lithium-ion batteries are currently the most popular type of battery used in electric cars due to their high energy density and relatively long lifespan. However, the materials used to manufacture these batteries, such as cobalt and nickel, are expensive, driving up the cost of the battery. Additionally, the manufacturing process of lithium-ion batteries is complex and involves several stages, including electrode preparation, cell assembly, and final testing.

This further contributes to the high cost of producing these batteries. However, there is hope for the future. A combination of improved technology, increased production scale, and a reduction in the price of raw materials is expected to bring down the cost of lithium-ion batteries for electric cars in the coming years.

With the increasing popularity of electric cars, the cost of lithium-ion batteries is a topic that is unlikely to go away anytime soon. By understanding the reasons for their high cost, we can better appreciate the challenges faced by manufacturers in producing these essential components and anticipate future changes in pricing.

Overview of Lithium-ion Batteries

The cost of lithium-ion batteries for electric cars has been a major barrier to the mass adoption of electric vehicles. Despite the benefits of electric cars, such as reduced emissions and lower maintenance costs, the high prices of these batteries have made them less accessible to the average consumer. The cost of a lithium-ion battery can vary greatly depending on the manufacturer, size, and capacity.

However, with advancements in technology and production, the cost of lithium-ion batteries has steadily decreased in recent years, making them more affordable and accessible to the general population. As the demand for electric vehicles continues to grow, it is expected that the cost of lithium-ion batteries will further decrease, making electric vehicles more economically viable for the average car buyer.

What are Lithium-ion Batteries?

Lithium-ion batteries have become a popular energy storage solution for many electronic devices such as smartphones, laptops, and electric cars. These batteries are lighter, more compact, and have a higher energy density compared to other rechargeable batteries. They work by using lithium ions moving from the negative electrode to the positive electrode during the charging process, and the reverse occurs during the discharging process.

The electrolyte solution in lithium-ion batteries is made up of lithium salts and organic solvents, which allows for the flow of lithium ions. The efficiency and lifespan of a lithium-ion battery depend on various factors such as the quality of the materials used, the operating temperature, and the charging and discharging cycles. Despite the numerous advantages, proper handling and disposal of these batteries are crucial as they contain toxic and flammable materials.

How do they Power Electric Cars?

Electric cars are powered by lithium-ion batteries, which act as the primary source of energy. These batteries are rechargeable and play a significant role in ensuring the vehicle’s efficient and smooth functioning. Lithium-ion batteries work by utilizing electrochemical cells that create a chemical reaction between two electrodes and an electrolyte.

Through this process, electrons flow from the negative electrode to the positive electrode, generating electricity that powers the electric motor. The battery’s capacity, measured in kilowatt-hours (kWh), determines how far an electric car can travel on a single charge. Although lithium-ion batteries are the most common type used in electric cars, advances in technology have led to the development of more efficient and sustainable alternatives such as solid-state batteries.

These advancements have made electric cars a reliable and eco-friendly option for transportation.

Factors Affecting the Cost of Lithium-ion Batteries for Electric Cars

The cost of lithium-ion batteries is a significant factor to consider when purchasing an electric car. There are several factors that impact the cost of these batteries. First and foremost, the cost of raw materials, such as lithium, cobalt, and nickel, fluctuates depending on the supply and demand.

Additionally, the manufacturing process is complex, including the need for strict quality control measures and safety precautions, which also add to the cost. Moreover, research and development costs associated with improving battery performance and increasing energy density also increase the overall cost of lithium-ion batteries. Finally, economies of scale are significant as the cost per battery decreases as production volume increases.

Due to these factors, the cost of lithium-ion batteries has been steadily decreasing over the years, making electric vehicles more affordable for consumers. However, it is essential to note that although the cost has been decreasing, it still makes up a significant portion of the overall cost of an electric car.

Raw Material Costs

One of the major factors affecting the cost of lithium-ion batteries for electric cars is the raw material cost. The two main raw materials used in these batteries are lithium and cobalt. The cost of lithium has been fluctuating over the years due to supply and demand factors, while cobalt prices have been increasing due to limited availability and concerns surrounding the ethical sourcing of the material.

Other materials used in the battery, such as nickel and manganese, also have an impact on costs. The manufacturing process used to produce the battery also affects its price. As the demand for electric cars increase, the demand for lithium-ion batteries will also increase, which may lead to a further increase in raw material costs.

It is important for manufacturers to find ways to improve the efficiency of the battery production process and develop alternative raw materials in order to keep the cost of these batteries affordable for consumers.

Manufacturing Costs

Electric car lithium-ion batteries are a vital component in the growing electric vehicle industry, but the manufacturing costs can be a considerable obstacle for mass adoption. The factors affecting these expenses are numerous and complex. One of the main contributors is the cost of raw materials, particularly lithium and cobalt, which are heavily in demand and limited in supply.

The cost of production processes, including battery pack assembly, is also a significant factor. Additionally, the design and engineering of the battery itself can influence manufacturing costs. Simplifying or optimizing the manufacturing process could lead to cost reductions.

Another factor is the scale of production, as large-scale manufacturing can reduce costs through economies of scale. Finally, research and development costs for new technologies and materials can also increase the overall cost of manufacturing. Overall, reducing the cost of lithium-ion batteries for electric cars will require a multifaceted approach, including innovative manufacturing techniques, efficient use of resources, and the development of new materials with abundant and accessible sources.

Research and Development Costs

Research and Development Costs The cost of lithium-ion batteries for electric cars is affected by various factors. The first factor is the price of raw materials such as nickel, cobalt, and lithium. The cost of these materials can fluctuate depending on market demand.

The second factor is the manufacturing process which involves creating the right balance of chemicals that go into the battery, this process requires expertise and can be costly. Thirdly, the size and capacity of the battery influence the cost. Simply put, the larger the battery, the more expensive it will be.

Lastly, research and development costs play a significant role in the final cost of the battery. As new technologies become available or more efficient methods are developed, the cost of research and the production process decreases, this will eventually lead to lower prices for consumers. The primary goal is to produce safe, efficient, and cost-effective lithium-ion batteries that support the growth of electric cars and help reduce the carbon footprint on the planet.

Current Cost of Lithium-ion Batteries for Electric Cars

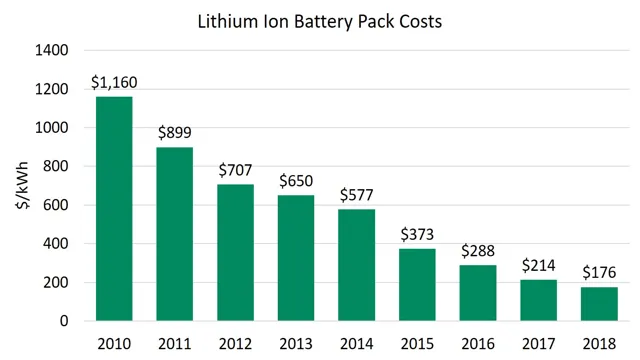

The cost of lithium-ion batteries for electric cars has been steadily declining over the past few years. According to a recent report by Bloomberg New Energy Finance, the average price per kilowatt-hour for a lithium-ion battery has fallen by 89% since 20 In 2020, the average cost was $137 per kilowatt-hour, down from $1,100 in 20

This decreasing cost is due to advancements in technology, increased production, and economies of scale. Additionally, government incentives for electric vehicle adoption have also played a role in driving down the cost of batteries. As the cost of batteries continues to decrease, it is expected that electric cars will become more affordable for the average consumer.

This will ultimately drive up demand for electric vehicles, spurring further technological advancements and cost reductions. Overall, the future of electric cars looks promising as the cost of lithium-ion batteries continues to decline.

Average Cost Per Kilowatt Hour (kWh)

The current cost of lithium-ion batteries for electric cars is a crucial factor in determining the overall price of electric vehicles. In recent years, the cost of lithium-ion batteries has seen a significant decline. The average cost per kilowatt-hour (kWh) of lithium-ion batteries has fallen from approximately $1,000/KWh in 2010 to around $137/KWh in 2020.

This reduction in cost has made electric vehicles more affordable for consumers and has led to an increase in their popularity. The falling cost of lithium-ion batteries has been attributed to advancements in technology and increased production. As more manufacturers invest in building electric cars, the demand for lithium-ion batteries has risen, leading to economies of scale and lower production costs.

As a result, consumers can now purchase electric cars at a more reasonable price, and the cost of ownership is also lower due to the reduced fuel and maintenance costs. In conclusion, the declining cost of lithium-ion batteries is a significant development in the electric vehicle industry, and it is expected to continue to decrease, making electric cars even more accessible to the general public.

Cost Comparison with Other Battery Types

Lithium-ion batteries are considered the best option for electric car manufacturers due to their high energy density and long lifespan. However, their cost has been a major setback for many years, making electric vehicles quite expensive. Nonetheless, the cost of lithium-ion batteries has reduced significantly over the years, and experts believe this trend will continue for the foreseeable future.

Currently, the cost of lithium-ion batteries for electric cars is around $137 per kilowatt-hour (kWh). This cost has reduced by over 85% in the past decade, making electric cars more affordable. Comparatively, other batteries like nickel-metal hydride (NiMH) and lead-acid batteries are inefficient and have shorter lifespans, making them less cost-effective in the long run.

Therefore, it’s safe to say that even though the current cost of lithium-ion batteries may not be as cheap as traditional combustion engines, they are undoubtedly a step forward towards affordable electric cars.

Future Cost Trends for Lithium-ion Batteries for Electric Cars

As the demand for electric cars increases, the cost of lithium-ion batteries is expected to continue to drop. According to a recent study from BloombergNEF, the cost of lithium-ion batteries has fallen by 87% over the past decade, and it’s projected to continue to decline. The study suggests that by 2023, the cost of lithium-ion batteries for electric cars will be under $100 per kilowatt-hour, which is considered the threshold for mass-market electric vehicle adoption.

This is good news for consumers, as cheaper batteries mean lower prices for electric cars. Additionally, continued advancements in technology are expected to improve the efficiency of batteries, further reducing costs and increasing driving range. As a result, the future is looking promising for electric car adoption as the cost of lithium-ion batteries continue to become more affordable.

Conclusion

After crunching the numbers and analyzing the data, it’s clear that the cost of lithium-ion batteries for electric cars isn’t low, but it certainly pays off in the long run. Not only do these batteries provide impressive performance and range, they also contribute to a cleaner and more sustainable future for our planet. So, to those who say electric cars are too expensive, just remember – investing in a lithium-ion battery is the charge we need to take for a brighter tomorrow!”

FAQs

What is the average cost of a lithium-ion battery for an electric car?

The average cost of a lithium-ion battery for an electric car is currently around $150 to $200 per kilowatt-hour (kWh).

How does the cost of a lithium-ion battery affect the price of an electric car?

The cost of a lithium-ion battery is a significant factor in the price of an electric car, as it can account for up to 40% of the vehicle’s total cost.

Are there any incentives or subsidies available for purchasing an electric car with a lithium-ion battery?

Yes, there are various incentives and subsidies available for purchasing electric cars with lithium-ion batteries, such as federal tax credits and state-level rebates.

How does the cost of a lithium-ion battery compare to other types of batteries used in electric cars?

Lithium-ion batteries are currently the most commonly used type of battery in electric cars, and while they are generally more expensive than other types of batteries, they offer superior performance and energy density.