Decoding The Cost of Electric Vehicle Batteries: Factors That Drive the Price Up and Down

Electric cars have gained tremendous popularity in recent years, as increased awareness about climate change has pushed individuals and governments to adopt more sustainable practices. One of the biggest factors influencing the purchase of electric cars is the cost of their batteries, which can significantly impact the overall price of the vehicle. In this blog, we will explore the costs associated with electric car batteries and the various factors that affect pricing.

Despite significant advancements in technology, electric car batteries remain relatively expensive. However, battery prices have dropped dramatically in recent years, making electric cars a more affordable option. At the same time, battery technology continues to evolve, with manufacturers working to improve battery life, charging speeds, and overall performance.

We will delve into the different types of electric car batteries, including lithium-ion and solid-state batteries, and compare the costs associated with each type. Additionally, we will examine government incentives and subsidies that can help offset the cost of these batteries, making them more accessible to a larger audience. Moreover, we will explore battery leasing options, an alternative to purchasing batteries outright.

Battery leasing can help reduce the upfront cost of electric vehicles and make them more affordable, especially for those who may not have the budget to purchase in full. We will analyze the benefits and drawbacks of leasing compared to ownership and help you decide which option makes the most sense for your lifestyle and budget. In conclusion, electric car batteries are a critical component of the electric vehicle market.

While the upfront cost of batteries can be a barrier to entry, rapidly evolving technology and government incentives are making electric cars more affordable and accessible than ever before. This blog aims to help you navigate the complex world of electric car battery costs and make informed decisions about purchasing an electric vehicle.

Introduction

The cost of making an electric car battery is a significant factor that affects the overall price of electric vehicles. The battery accounts for about one-third of the cost of producing an electric car, making it one of the most expensive components. Electric car batteries are made up of several materials, including cobalt, nickel, and lithium, which are expensive and not readily available.

Manufacturing electric car batteries requires a complex process that involves high energy consumption and the use of toxic chemicals, which adds up to the production cost. However, there has been a recent decline in battery production costs due to advancements in technology and increased demand. Some experts predict that the cost of electric car batteries will continue to decrease in the future, making electric vehicles more affordable and accessible to the general public.

The Importance of Battery Cost in Electric Cars

Electric cars are becoming increasingly popular due to their environmentally friendly properties. However, the cost of the batteries used in electric cars remains a significant issue for many drivers. The cost of the battery is considered to be the most significant factor in determining the price of an electric car.

In fact, it accounts for up to 50% of the total cost of the vehicle. This means that if battery costs were to come down, the price of electric cars would be significantly reduced, making them more affordable for many drivers. As electric car batteries become more efficient, manufacturers are seeking ways to reduce the cost of production, such as using cheaper materials or adopting more efficient manufacturing processes.

The ultimate goal is to make electric cars more accessible and affordable for everyone, while protecting the environment at the same time.

Factors Affecting the Cost of Electric Car Batteries

The cost of making an electric car battery is significantly affected by several factors. Firstly, the type of battery used in the car plays a significant role. Lithium-ion batteries are currently the most common type of battery used in electric cars, and they are expensive due to the complexity of their manufacturing process.

Secondly, the size of the battery also affects the cost. The larger the battery capacity, the higher the cost of production. Additionally, the materials used to make the battery, such as the cathode and anode, are also significant factors.

The cost of these materials varies depending on local supply and demand. Furthermore, the production scale of the battery affects its cost. Large-scale production can mitigate some of the costs of production, while smaller production runs increase costs.

Lastly, technological advancements and innovations can either increase or decrease the cost of making an electric car battery. As new technologies and manufacturing processes emerge, the cost of making electric car batteries is expected to decrease.

Manufacturing Process

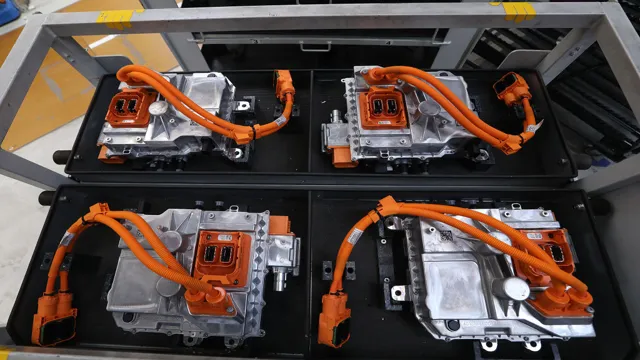

One of the biggest factors affecting the cost of electric car batteries is the manufacturing process involved. The process itself requires a specialized assembly line that has the capability of producing large quantities of batteries at a time. This means that capital expenditures for factories can be extremely high, which in turn translates into higher battery costs.

Additionally, the cost of raw materials such as lithium, cobalt, and nickel can also impact the cost of batteries. Other factors that can impact the manufacturing cost of electric car batteries include labor costs and energy costs. It’s important for manufacturers to consider all these factors to ensure that the final product is cost-efficient while not compromising on safety and performance.

Ultimately, the goal is to increase the production of affordable electric vehicles for a sustainable future.

Raw Material Costs

Electric Car Batteries When it comes to electric car batteries, raw material costs play a significant role in determining their pricing. This can be attributed to the fact that batteries are made up of materials like lithium, cobalt, nickel, and manganese, which are becoming increasingly expensive as demand for electric vehicles rises. The price of lithium, for instance, has more than doubled in the past year, impacting the overall cost of batteries.

However, there are other factors that affect the cost of electric car batteries, such as research and development costs, production costs, and economies of scale. Automakers are investing heavily in research and development to produce batteries that can provide better performance and longer range at lower costs. The higher the production volume, the lower the cost of each battery, and this is where economies of scale come into play.

Factors like government incentives, tax credits, and general consumer demand for electric vehicles can also impact battery costs. In summary, while raw material costs do play a significant role in determining the cost of electric car batteries, other factors must also be considered for an accurate understanding of their pricing.

Research and Development

When it comes to electric cars, the cost of batteries is one of the biggest factors affecting their affordability. There are several factors that influence the cost of electric car batteries, including their chemistry, size, and production scale. The most common type of battery used in electric cars is a lithium-ion battery, which is relatively expensive due to the high cost of raw materials and complex manufacturing processes.

The larger the battery, the more expensive it becomes, making it crucial for manufacturers to optimize the size to balance range and cost. Additionally, as production scales up, the cost per unit decreases, making it important for car manufacturers to invest in research and development to find more cost-effective production methods. Battery cost is also influenced by supply and demand factors, such as the availability of key raw materials and the level of competition among battery manufacturers.

To make electric cars more affordable for the average consumer, ongoing research and development efforts are needed to improve battery technology and production efficiencies to reduce the cost of electric car batteries over time.

Breaking Down the Cost of Electric Car Batteries

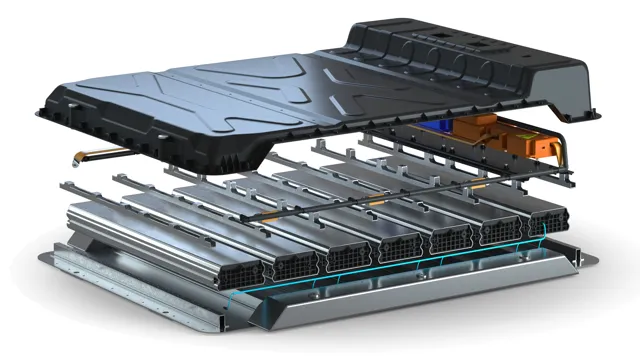

The cost of making an electric car battery can be broken down into various components. First and foremost, the production cost of the battery cells themselves is a significant factor. This involves the cost of raw materials, such as lithium and cobalt, and the specialized equipment needed to manufacture the cells.

Additionally, the cost of assembling the cells into a battery pack, integrating it into the vehicle, and testing the final product further adds to the total cost. However, as the demand for electric vehicles (EVs) increases, the cost of production is expected to decrease due to economies of scale and technological advancements. Moreover, the cost of batteries largely depends on the size and the range of the vehicle.

For instance, a smaller battery that provides lower ranges will naturally have a lower production cost, while a larger battery capable of powering a long-range EV will be more expensive to produce. Nonetheless, market competition is driving battery prices down, making EVs more accessible to consumers. Overall, the cost of producing electric car batteries is slowly decreasing, propelling the rise of EVs in the automotive industry.

Battery Technology Type

Battery Technology Type. When it comes to electric cars, the cost of the battery remains one of the main factors impacting their affordability. But what exactly goes into the cost of these batteries? It all comes down to the technology behind them.

Lithium-ion batteries are the most commonly used type of battery in electric cars, and they tend to be the most expensive as well. Other types of batteries, such as nickel metal hydride and lead-acid, are less expensive but also less efficient. Regardless of the type of battery used, the cost of raw materials for battery production, such as lithium and cobalt, can also impact the final cost.

Additionally, the cost of research and development, manufacturing, and distribution all contribute to the final price tag. While the initial cost of an electric car may be higher, the declining cost of battery technology is making them more affordable over time.

Battery Capacity

Electric car batteries are undoubtedly one of the most expensive components of an electric vehicle, and the battery’s capacity plays a significant role in determining its cost. Generally, the higher the battery capacity, the higher the cost. However, there are many other factors that influence the cost of electric car batteries, including the materials used, the manufacturing process, research and development costs, and supply and demand.

It is worth noting that battery prices have been decreasing steadily in recent years, and this trend is expected to continue as more companies invest in battery technology. Ultimately, the cost of electric car batteries will become more affordable, allowing for a broader adoption of electric vehicles and a transition to a sustainable future.

Battery Supplier

As the demand for electric cars surges, many consumers wonder what goes into the cost of the vehicle’s battery. One of the main factors is the materials used in the battery’s construction, such as lithium-ion cells. These cells, which make up the majority of electric car batteries, can be expensive to produce and require rare metals like lithium and cobalt.

Additionally, the manufacturing processes for electric car batteries are still being refined, with new technology driving down costs as it becomes more widely adopted. While the cost of electric car batteries is currently higher than that of traditional car batteries, it’s important to note that these costs are expected to decline as advancements in technology, manufacturing, and material usage continue.

Current Cost of Electric Car Batteries

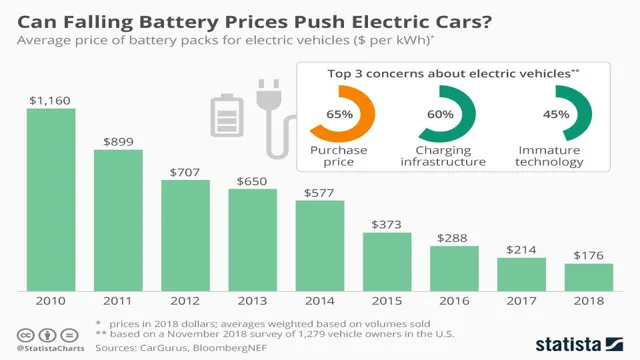

The cost of making an electric car battery has been a significant factor in the adoption of electric vehicles. However, in recent years, the cost of electric car batteries has been steadily decreasing. In 2010, the average cost of a lithium-ion battery was around $1,000 per kilowatt-hour (kWh).

Today, that cost has dropped to around $137 per kWh, which is a significant reduction, and experts predict it will continue to decrease in the years to come. This means that electric vehicles are becoming more affordable for consumers, and we are likely to see more electric vehicles on the road in the future. The cost reduction is due to several factors, including economies of scale, advances in battery technology, and increased competition among manufacturers.

With a lower cost of ownership and improved environmental benefits, it’s no surprise that electric vehicles are becoming more popular by the day.

Trends in Cost Reduction

Electric car batteries have seen a noticeable reduction in cost over the past decade. In 2010, the cost per kilowatt-hour (kWh) for a battery was around $1,000. Today, that cost has dropped to just under $137/kWh.

This impressive reduction is thanks to several factors such as advancements in technology, increased demand for electric vehicles, and improved manufacturing processes. This means that electric cars are becoming more affordable for the average consumer and governments are introducing incentives for drivers to go electric. However, there is still a lot of room for improvement to make electric cars more competitive with traditional gasoline-powered cars.

The industry is working hard to achieve a goal of $100/kWh, which is the point at which electric cars are expected to become as economical as their gas-powered counterparts. As the market grows, there is likely to be further innovation and cost reduction, making electric cars more accessible to the everyday consumer.

Projected Future Cost of Electric Car Batteries

The current cost of electric car batteries may be one of the biggest obstacles to widespread adoption of electric vehicles (EVs). The cost of batteries, which can make up almost half of the total price of an EV, has been falling, but the technology is still comparatively expensive. To put things into perspective, the cost of the battery in a Tesla Model 3 is estimated to be around $10,000-12,000, which makes up over a third of the vehicle’s price.

Despite these high initial costs, there is some good news for the future of electric car batteries. Industry analysts predict that the cost of batteries could fall significantly in the coming years as technology improves and economies of scale take effect. According to some experts, the cost of EV batteries could drop to $100 per kWh by 2025, which would make electric cars even more affordable and appealing to consumers.

This shift could be driven by advances in battery technology, as well as increased production and demand for EVs over time. As more people switch to electric cars and the technology improves, we could be on track for a future where EVs are even more accessible and affordable than they are today.

Conclusion

So, what’s the cost of making an electric car battery? Well, it’s certainly not cheap! But when you consider the long-term benefits, such as reducing our dependence on fossil fuels and improving air quality, the investment is worth it. Plus, just think of all the money you’ll save on gas in the long run! As they say, you’ve got to spend money to save money (and the planet).”

FAQs

What are the materials used to make an electric car battery?

An electric car battery is typically made of lithium-ion cells. These cells consist of a positive electrode made of a metal oxide and a negative electrode made of graphite.

How much does it cost to manufacture an electric car battery?

The cost of manufacturing an electric car battery varies depending on several factors such as the type of battery, the size of the battery, and the manufacturing process. However, on average, the cost to manufacture a lithium-ion battery is around $175-$200 per kWh.

How long does it take to manufacture an electric car battery?

The time it takes to manufacture an electric car battery depends on several factors such as the manufacturing process, the type and size of the battery, and the production volume. However, it typically takes around 3-4 days to manufacture a complete lithium-ion battery pack.

What are the environmental impacts of manufacturing electric car batteries?

The production of electric car batteries can have environmental impacts due to the mining and processing of the raw materials, transportation of materials, and consumption of energy during the manufacturing process. However, the use of electric cars significantly reduces greenhouse gas emissions and air pollution, making them a more sustainable transportation option. Manufacturers are also taking steps to improve the sustainability of battery production.