Unmasking the Shocking Truth: The Real Cost of Manufacturing Electric Car Batteries

Electric cars have become increasingly popular in recent years as people search for more environmentally friendly options for their daily commutes. As the world moves towards a greener future, the demand for electric vehicle batteries continues to rise. With this in mind, have you ever wondered about the cost of making electric car batteries? The answer is not a simple one.

The cost of producing electric vehicle batteries depends on a variety of factors, including the type of battery, the materials used, and the manufacturing process. Additionally, advancements in technology bring changes to production costs and economies of scale, meaning the cost of making electric car batteries is constantly fluctuating. In this blog, we will explore the factors that impact the cost of making electric car batteries.

By understanding the production process and the costs involved, we can better appreciate the value of this essential component of electric vehicles. So, let’s dive in and explore what goes into making the batteries that power our electric cars.

Overview of Electric Car Batteries

The cost of making electric car batteries largely depends on the type of battery used and the materials required. Lithium-ion batteries, which are commonly used in electric cars, have seen a significant decrease in cost over the past decade due to advances in technology and increased production scale. However, the cost of materials like cobalt, nickel, and lithium can still be high.

Batteries with higher energy density and longer life cycles tend to be more expensive, but can also result in greater overall savings for the consumer in the long run. The development of new, more affordable battery technologies continues to be a priority for the electric vehicle industry. As the demand for electric cars grows, we can expect to see further decreases in the cost of battery production and increased accessibility for consumers.

Composition of Electric Car Batteries

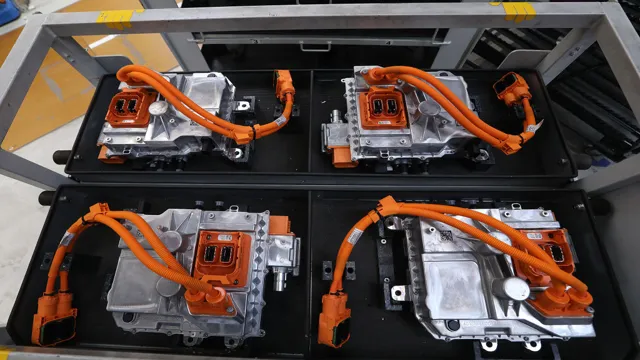

Electric car batteries are made up of several components that work together to power the vehicle. These components include the cathode, the anode, and the electrolyte. The cathode and the anode are the two electrodes that help facilitate the flow of electric current in the battery while the electrolyte is responsible for conducting the ions between the two electrodes.

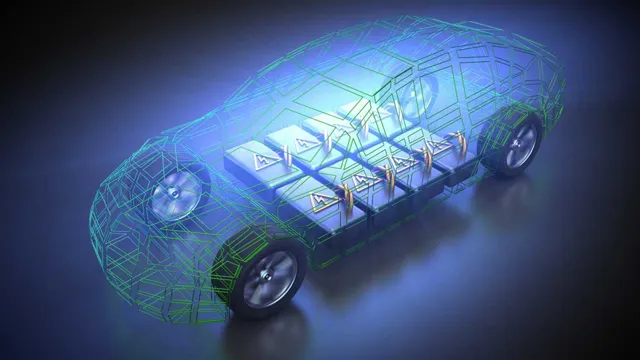

Most electric car batteries are made up of lithium-ion cells which are packed together in modules to create a battery pack. This pack is designed to withstand the high voltage and current that is required to power an electric car. The overall composition of electric car batteries is vital to the performance and range of electric cars, and advancements in battery technology continue to improve the efficiency and sustainability of these vehicles.

As more research is conducted in this field, we can expect even greater strides in the composition of electric car batteries, making them more accessible and affordable for people around the world.

Factors Affecting the Cost of Electric Car Batteries

Electric car batteries have come a long way since the first production models. While early batteries were inefficient and costly, modern iterations are more powerful and dependable. These batteries are the heart of an electric vehicle, and they represent a significant chunk of the overall cost.

Factors such as production scale, technical advancements, and material costs play a crucial role in determining the cost of these batteries. Large-scale production lowers costs, while technological advancements increase capacity and reduce weight. As for material costs, raw materials like cobalt, lithium, and nickel can fluctuate in price, making it challenging to forecast battery costs accurately.

Ultimately, the price of a battery can affect the car’s overall cost and factor into the buyer’s decision to go electric. Despite this, the battery’s cost has been trending downwards in recent years, and with the right policies and market trends, it is expected to continue to do so.

Cost Breakdown of Electric Car Batteries

The cost of making electric car batteries is a topic that has been gaining a lot of attention in the automotive industry. While the prices of electric cars are gradually becoming more affordable, the cost of making the batteries continues to be a challenge. The cost of materials for the batteries is still quite high, with lithium being the most expensive component.

Another challenge in the making of these batteries is the production process which requires specialized equipment and skilled labor. However, with advancements in technology and increased demand for electric cars, researchers anticipate a decline in the cost of making these batteries. It is projected that the cost of making electric car batteries will drop by as much as 50% by 202

As these batteries become more economical to produce, the prices of electric cars can be expected to become more competitive with traditional gasoline-powered vehicles.

Raw Materials

Electric car batteries have revolutionized the automotive industry, making it easier for people to switch from traditional gasoline engines to cleaner electric-powered cars. However, the cost of electric car batteries is still one of the main hindrances preventing mass adoption. To understand the cost breakdown of electric car batteries, it’s necessary to look at the raw materials used to produce them.

This includes lithium, cobalt, nickel, manganese, graphite, and aluminum. These materials account for approximately 70% of the battery’s total cost. The price of these materials fluctuates frequently, affecting the overall cost of manufacturing electric car batteries.

Despite this, companies like Tesla and Panasonic are working on reducing the cost by improving battery materials, manufacturing processes, and technological innovations. As battery technology continues to progress, it’s expected that the cost of electric car batteries will decrease, making electric cars more affordable for the masses.

Production Process

Electric car batteries are an integral part of any electric vehicle, and understanding the cost breakdown of these batteries can be helpful in understanding the overall cost of owning an electric car. The production process of electric car batteries includes a number of different factors, such as the cost of raw materials, labor, transportation, and research and development. One of the main components of electric car batteries is the lithium-ion battery, which is made up of several different elements, including lithium, cobalt, nickel, and manganese.

The cost of these raw materials can fluctuate, depending on the current market conditions and supply-and-demand dynamics. Additionally, the manufacturing process for electric car batteries requires a significant amount of manpower and technical expertise, which also impacts the overall cost. The research and development (R&D) process is another important factor that can make a significant impact on the cost of electric car batteries, as this is where improvements and innovations are developed to make the batteries more efficient, powerful, and cost-effective.

Overall, the cost breakdown of electric car batteries is complex, and understanding it is crucial for predicting the future of electric car technology and making informed purchasing decisions.

Labor Costs

Electric car batteries are a crucial component of electric vehicles and account for a significant portion of the overall cost. Labor costs associated with the production of these batteries can vary depending on factors such as location and production technology. Generally, labor costs account for about 10-15% of the total battery pack cost.

In countries with higher wages and more stringent labor laws, labor costs can be a larger percentage of the total cost. However, as automation and production technologies improve, labor costs are expected to decrease over time. It is also worth mentioning that while labor costs may vary, the quality of the workmanship must be high to ensure the battery pack’s safe and reliable performance.

Ultimately, while labor costs are an essential factor to consider when examining the cost breakdown of electric car batteries, they are just one piece of a larger puzzle in the transition towards more sustainable transportation.

Electric Car Battery Cost Trends

As the global demand for electric cars increases, so does the need for affordable and efficient batteries. The cost of making electric car batteries has been a major concern for manufacturers, but recent trends show promising developments. Experts predict that the cost of producing batteries will decrease by 50% in the next few years, driven by advancements in technology and increased production.

This reduction in cost will make electric vehicles more accessible to consumers around the world, resulting in a greener future. Although the upfront investment in an electric car may be higher than that of a traditional vehicle, the savings in fuel costs over time will more than make up for it. So, if you’re considering making the switch to an electric car, now may be the perfect time to take the plunge.

Reduction in Battery Costs Over the Years

Over the past decade, the cost of electric car batteries has seen a significant reduction. This shift in battery prices has been a significant driver in the adoption of electric vehicles (EVs). In 2010, a typical EV battery pack cost around $1,100 per kilowatt-hour (kWh), while today, the cost has dropped more than 80% to around $137 per kWh.

The cost continues to decline as advancements in technology drive efficiencies in battery manufacturing, resulting in higher energy density and longer-range vehicles. With current trends, it is anticipated that by 2030, the cost of EV batteries could fall to as low as $62 per kWh, making EVs cheaper to produce than gasoline-powered cars. As the cost of batteries trends downward, it will continue to be a significant factor in the future growth of the EV market.

Expected Future Cost Reductions

Electric car battery cost trends are expected to continue decreasing over the next few years. The adoption of electric vehicles has led to an increase in manufacturing, resulting in economies of scale. Battery prices have also dropped due to advancements in technology and materials used in battery production.

Many car manufacturers are also investing in R&D to create cheaper and more efficient batteries. However, it’s important to note that the rate of decline may not be consistent as there are different factors that contribute to the cost. One such factor is the availability and cost of raw materials like lithium, nickel, and cobalt used in batteries.

Therefore, we can expect some bumps in the road, and cost reduction may not be linear.

Conclusion

After crunching the numbers, it’s clear that the cost of making electric car batteries is shockingly high. But don’t worry – the future of EV technology is bright, and with continued innovation and advancements, we can be sure that the price tag will eventually come down and make owning an electric vehicle more accessible and affordable for everyone. So let’s keep driving towards a cleaner, greener future – one mile at a time!”

FAQs

What is the current cost of making electric car batteries?

The cost of making electric car batteries depends on several factors, such as the size of the battery, the type of materials used, and the manufacturer. On average, the cost ranges from $100 to $200 per kWh, but it is expected to decrease as technology advances and economies of scale are achieved.

Why are electric car batteries more expensive than traditional car batteries?

Electric car batteries are more expensive than traditional car batteries because they use more advanced technology and higher-quality materials, such as rare earth metals. Moreover, the production of electric car batteries requires a more complex manufacturing process, which adds to the overall cost.

Will the cost of making electric car batteries decrease in the future?

Yes, it is expected that the cost of making electric car batteries will decrease in the future as technology improves and economies of scale are achieved. Several manufacturers are already investing heavily in battery R&D, and some even claim to have developed battery technologies that could significantly reduce the cost.

How can the cost of making electric car batteries affect the adoption of electric vehicles?

The cost of making electric car batteries is a crucial factor that determines the cost of electric vehicles and their affordability for consumers. As such, a decrease in the cost of making electric car batteries could lead to a wider adoption of electric vehicles as they become more accessible and reasonably priced.