Unveiling the Truth: The Real Cost to Build an Electric Car Battery

Have you ever wondered how much it costs to produce an electric car battery? The rise of electric vehicles has caused a significant shift in the automotive industry, and the topic of battery production cost has become a hotly debated issue. The cost of the battery is one of the most significant factors in determining the price of electric vehicles and ultimately their market viability. In this blog post, we will take a deep dive into the cost of electric car batteries, including the factors that influence their price and what the future holds for battery technology.

So buckle up and join us as we explore the cost of making an electric car battery.

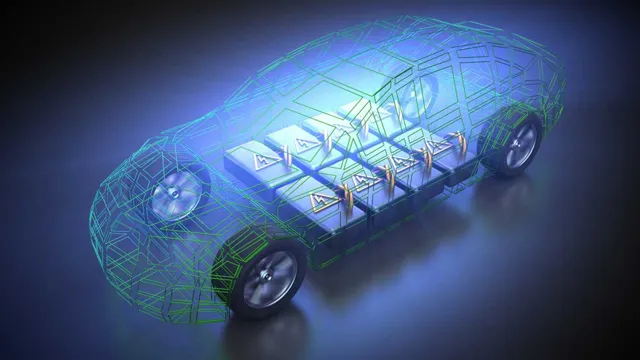

Intro to Electric Car Batteries

When it comes to electric cars, the battery is one of the most important components that determines the car’s overall performance and price. In fact, the cost to make an electric car battery can vary significantly and can constitute a large portion of the car’s total cost. The battery pack typically includes hundreds of individual cells, each containing a mix of lithium-ion and other materials that help regulate the flow of electricity.

The costs of these materials, along with the cost of manufacturing and assembling the battery, make up the cost to produce a high-quality battery. However, the price of these batteries has been declining in recent years due to advancements in technology, increased production, and economies of scale. As technology continues to improve and production volumes increase, it is expected that the cost of electric car batteries will become more affordable, making them a more accessible option for consumers.

Understanding Lithium-Ion Batteries

Lithium-ion batteries are the backbone of electric cars and understanding how they work is key to unlocking their full potential. These batteries are made up of several cells that store electric charges and are rechargeable. The main advantage of these batteries is that they are lightweight, take up less space, and offer a greater range than traditional lead-acid batteries.

However, their downside is that they are more expensive to produce and have a limited lifespan. The cells in these batteries contain positive and negative electrodes that are separated by a thin layer of electrolyte. This layer allows for the flow of ions between the electrodes when the battery is charged and discharged.

It is important to note that the lifespan of the lithium-ion battery can be greatly affected by high temperatures, overcharging, and extreme usage. With proper care and maintenance, lithium-ion batteries can offer great benefits to electric cars.

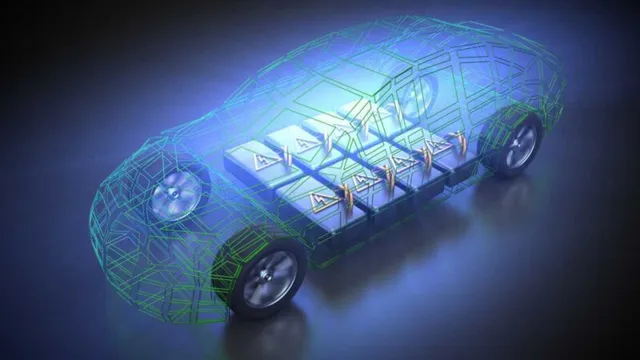

Factors Affecting Electric Car Battery Costs

Electric Car Battery Costs Electric car batteries are an essential component of electric vehicles, powering the electric motor that propels the car. The cost of electric car batteries is a crucial factor in determining the price, affordability, and adoption rate of electric cars. There are various factors affecting electric car battery costs, including the type of battery, size, energy density, production volume, manufacturing costs, and raw materials used.

Lithium-ion batteries are currently the most common type of battery used in electric cars, and the cost of these batteries has been steadily declining over the past decade due to advancements in technology and economies of scale. However, the cost of raw materials such as lithium, cobalt, and nickel can impact battery costs. Furthermore, the size and energy density of the battery also play a critical role in determining its cost.

As demand for electric vehicles continues to grow and production volumes increase, it is expected that the cost of electric car batteries will continue to decrease, making electric cars more accessible and affordable for consumers.

The Price Tag of Electric Car Batteries

Have you ever stopped to think about how much it costs to make an electric car battery? The truth is that the price tag of these batteries can be quite steep. In fact, it’s estimated that the cost to manufacture a typical electric car battery can range from $100 to $200 per kilowatt-hour. This means that a battery pack with a capacity of 60 kWh, which is common among many electric vehicles, could cost anywhere from $6,000 to $12,000 to produce.

While the cost of electric car batteries has come down significantly in recent years, it is still one of the biggest hurdles facing the widespread adoption of electric vehicles. That said, as technology continues to improve and economies of scale kick in, we can expect the cost of electric car batteries to continue to fall, helping to make electric vehicles more affordable and accessible to the masses.

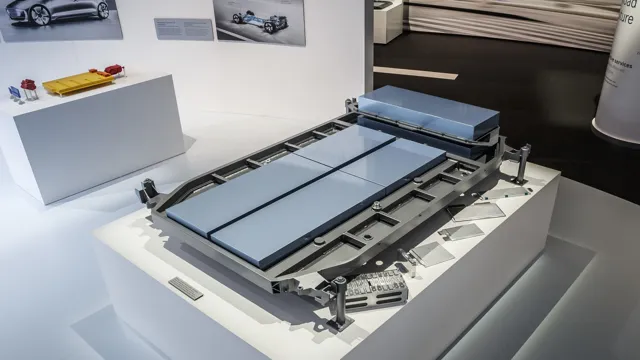

Breaking Down the Cost of a Lithium-Ion Battery

The cost of a lithium-ion battery, which is the power source for most electric cars, is a significant factor in the price tag of these vehicles. There are several factors that influence the cost of these batteries, including the raw materials required to manufacture them and the production process itself. The most important factor, however, is the size and capacity of the battery.

Larger, more powerful batteries require more materials and are more complex to manufacture, which drives up the price. Additionally, the cost of these batteries is also affected by supply and demand factors, as well as economies of scale. As prices for electric car batteries continue to drop, we can expect to see even more affordable options for consumers in the future.

However, for now, electric vehicles remain a premium option for those who prioritize sustainability and performance in their car purchases.

Comparing Electric Car Battery Costs Vs. Gasoline Cars

When it comes to the price tag of electric car batteries, there’s no denying they are still more expensive than their gasoline counterparts. However, the cost of electric car batteries has been steadily declining in recent years, and experts predict they could reach price parity with gasoline cars by as early as 202 The initial purchase price of an electric car may be higher due to the battery, but over time, owners can save money on fuel and maintenance costs.

Electric cars require less maintenance since they have fewer moving parts compared to gasoline cars. Plus, the cost of electricity to charge an electric car is often cheaper than the cost of gasoline. While electric car batteries may be pricier upfront, the long-term savings and reduction in carbon emissions make them a smarter and more sustainable choice for the future.

Projected Reduction in Electric Car Battery Costs

Electric Car Battery Costs The price tag of electric car batteries has always been a major concern for consumers and manufacturers alike. However, with technological advancements, experts are projecting a significant reduction in electric car battery costs in the coming years. This is good news for those who want to switch to electric vehicles but have been put off by the high cost of batteries.

According to industry projections, the cost of batteries is expected to fall by more than 50% in the next five years, making electric cars more affordable for the masses. This reduction in battery costs is attributed to advancements in battery technology, an increase in battery production, and economies of scale. With the rising demand for electric vehicles, more battery manufacturers are entering the market, leading to increased competition and lower prices.

As a result, electric cars will become more accessible and affordable to a wider audience. This is a great development for those who are looking to make the switch to a more sustainable and eco-friendly mode of transportation.

Factors Influencing Electric Car Battery Pricing

The cost to make an electric car battery can be influenced by various factors. Firstly, the type of battery technology used plays a significant role in determining the cost. Lithium-ion batteries are the most common battery technology used in electric cars.

However, other advanced battery technologies such as solid-state batteries or lithium-sulfur batteries may potentially offer better performance and lower costs in the future. Secondly, the cost of raw materials such as lithium, cobalt, and nickel can significantly impact the overall cost. The supply and demand of these materials, as well as their availability, can cause prices to fluctuate.

Additionally, the manufacturing process can also affect the cost of making an electric car battery. Automakers may need to invest in new facilities and equipment to increase production levels, driving up costs in the short term. Lastly, competition within the market could also impact pricing.

The more electric vehicles that are produced and sold, the more economies of scale can be achieved, potentially leading to a reduction in the cost of batteries.

Cost of Raw Materials

One of the key factors affecting the pricing of electric car batteries is the cost of raw materials. Lithium-ion batteries, the most common type of battery used in electric cars, rely on several raw materials, including lithium, cobalt, nickel, and graphite. These materials are essential to the battery’s performance, energy density, and overall lifespan.

However, their prices can fluctuate dramatically based on supply and demand, geopolitical tensions, and mining regulations. For instance, cobalt prices surged in 2017 following reports of child labor in the Democratic Republic of Congo, a major producer of cobalt. Similarly, lithium prices have been impacted by oversupply and growing competition among producers.

Thus, the costs of raw material procurement and processing have a significant impact on the final price of electric car batteries.

Energy Storage Capacity

Electric car battery pricing is influenced by multiple factors, including energy storage capacity. The amount of energy stored in a battery is a significant determinant of its cost. Electric cars with a higher energy storage capacity generally cost more than those with smaller ones.

Additionally, the type of battery technology used can influence the price. Lithium-ion batteries are currently the most widely used batteries in electric vehicles, but other technologies such as solid-state batteries and flow batteries are also emerging. The availability and cost of materials used to manufacture these batteries can affect pricing.

Finally, the battery’s durability and lifespan can also influence price. A battery with a longer lifespan may cost more initially but could end up being more cost-effective in the long run. So, the energy storage capacity of electric car batteries is indeed one of the most significant factors influencing pricing, but it does not stand alone.

Conclusion and Future of Electric Car Batteries

In the end, the cost to make an electric car battery may seem shocking at first glance, but it’s important to remember that technology is constantly evolving. As more research and development goes into creating better, more efficient batteries, we can expect the cost to come down and make electric vehicles more accessible to all. So while the sticker price may be high now, the long-term benefits to both our wallets and the environment make it a smart investment for the future.

“

FAQs

What factors affect the cost to make an electric car battery?

The cost to make an electric car battery is influenced by several factors, including the type of battery chemistry, the production scale, and the availability of raw materials.

How much does it cost to make an electric car battery?

The cost to make an electric car battery varies depending on the type of battery, the size of the battery, and the production scale. However, on average, it can cost between $100 to $200 per kilowatt-hour.

Can the cost of making electric car batteries decrease in the future?

Yes, as the demand for electric cars grows, the cost of producing electric car batteries is expected to decrease due to the economies of scale. Additionally, advancements in battery technology may also make the production process more efficient and cost-effective.

How do raw material costs affect the price of electric car batteries?

Raw material costs, such as lithium, cobalt, and nickel, can have a significant impact on the price of electric car batteries. Any fluctuations in the supply and demand of these materials can cause the cost to make an electric car battery to fluctuate as well.