The Shocking Truth: Revealing the Real Cost to Make an Electric Car Battery

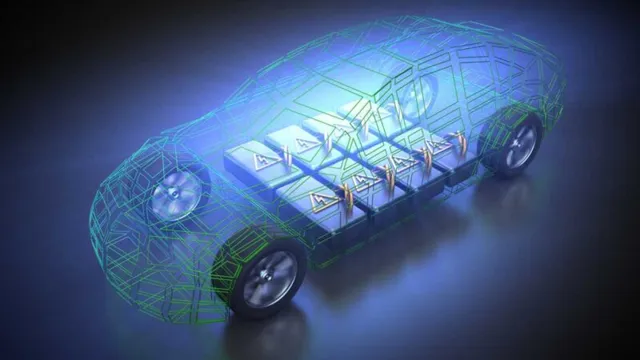

Electric cars are rapidly gaining popularity due to their eco-friendliness and cost-efficiency. However, one of the biggest concerns of potential buyers is the cost of electric car battery. The battery is the heart of an electric car, and it’s not surprising that it plays a significant role in determining the overall cost of the car.

In this blog, we’ll dive into the nitty-gritty details of electric car battery cost, exploring why it’s expensive and how it’s changing over time. So if you’re curious about electric cars but haven’t yet made the leap, keep reading to find out everything you need to know about battery cost!

Factors that Affect Cost

The cost to make an electric car battery can vary significantly depending on several factors. One of the most significant factors is the type of battery used, with lithium-ion batteries being the most common and expensive option currently available on the market. Another factor to consider is the size and capacity of the battery, with larger batteries naturally costing more money to produce.

The manufacturing process and location can also affect the cost, as different regions may have varying labor and material costs. Finally, the demand for electric vehicles also plays a role in battery costs, as the economies of scale can help drive down costs as more batteries are produced. Overall, the cost to make an electric car battery can range from several thousand dollars to tens of thousands of dollars, making it a significant investment for electric vehicle manufacturers.

Battery Chemistry

When it comes to batteries, the cost is a critical factor that can be influenced by multiple factors. One of the primary factors that impact the cost of battery technology is the type of chemistry used in the battery cell. Lithium-ion batteries, for instance, are commonly used in consumer electronics, electric vehicles, and stationary energy storage systems.

While they are relatively expensive to manufacture, they offer a high energy density and long cycle life compared to traditional lead-acid batteries. Another factor that can affect the cost of battery chemistry is the availability of raw materials. For example, cobalt, a critical component in lithium-ion batteries, has faced supply chain issues and price volatility.

Therefore, the shift towards more sustainable battery chemistries like nickel, manganese, and cobalt-free electrodes is underway to address these issues. It is essential to consider these factors while developing battery technologies to ensure that the cost of the batteries remains at a reasonable level and is sustainable.

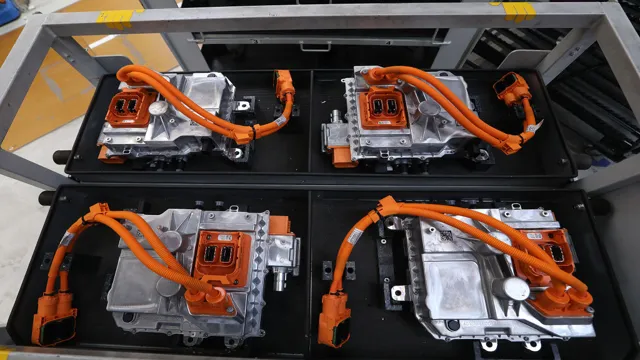

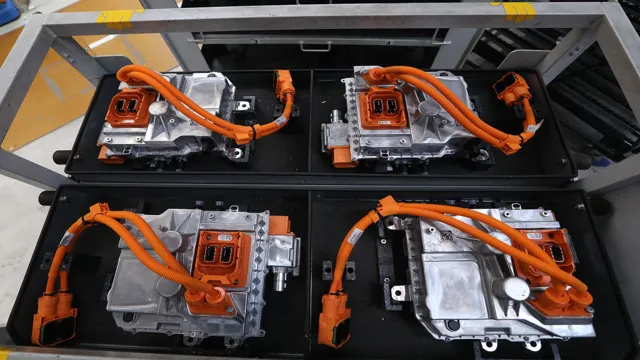

Manufacturing Process

When it comes to manufacturing products, there are numerous factors that can influence the final cost. These may include the materials used, the complexity of the production process, and the level of automation employed. Raw materials, parts, and components can all impact price, especially if they need to be sourced from different suppliers.

Additionally, the more intricate the design or assembly, the more expensive it can be to produce. Labor costs are also a crucial factor, and automating certain parts of the process can improve efficiency and reduce costs. Quality control measures are another expense, as they ensure that the end product meets the necessary standards.

These factors all contribute to a product’s final cost, and manufacturers need to weigh them against each other to achieve the right balance for their business. By considering these factors and finding ways to optimize production, manufacturers can keep costs down while also ensuring the quality and consistency of their products.

Battery Capacity

Battery capacity is a crucial factor that determines the cost of a battery. The higher the capacity of the battery, the more expensive it will be. This is because high-capacity batteries require more materials to produce, driving up the manufacturing cost.

Additionally, larger batteries need more advanced technology to ensure that they can be charged and discharged safely without damage. This technology adds to the cost of the battery. However, the capacity of a battery is not the only factor that affects its cost.

Other factors that contribute to the expense of a battery include the technology used, the materials used in its production, and the brand name. Nevertheless, the capacity of a battery remains one of the most significant factors that determine its cost. Therefore, when choosing a battery, it’s essential to choose one with the right capacity that fits your budget.

A higher-capacity battery may cost more in the short term, but it will provide more energy and potentially save you money in the long run.

Raw Materials

Raw materials are an essential component for the production of goods and services. The cost of raw materials can fluctuate based on a variety of factors. One significant factor that affects the cost of raw materials is supply and demand.

When the supply of raw materials is high, the price tends to go down, whereas when the supply is low, the price often rises. Another factor that affects the cost of raw materials is transportation expenses. Raw materials must often be transported from where they are sourced to the manufacturing facility, and fuel prices or availability of transport options can impact the cost of these materials.

Additionally, the cost of labor in the location where raw materials are sourced can affect the overall cost of materials. Inflation can also play a role in raw material costs, as inflation can lead to increased costs for transportation, labor, and other expenses associated with the production of materials. These factors, among others, can impact the cost of raw materials and ultimately affect the cost of the end product.

Current Cost Trends

The cost to make electric car batteries has been steadily decreasing in recent years due to advancements in technology and economies of scale. These developments have led to lower production costs, which have been passed down to the consumer. In fact, some experts predict that the cost of an electric car battery could drop to as low as $80 per kilowatt-hour by 2025, making electric cars relatively more affordable and accessible.

This is a significant drop compared to the $1,100 per kilowatt-hour that it cost only a decade ago, and bodes well for the continued growth of the electric car market. As more and more people shift towards environmentally-friendly transport, it is likely that we will continue to see further developments in electric car technology and production costs, making them even more affordable and accessible to the general public.

Electric Vehicle Market Growth

When it comes to the electric vehicle market, one major factor that consumers consider is the cost. Over the years, the cost of electric vehicles has been decreasing, making them a more affordable option for those in the market for a new car. This is because advancements in technology have led to more efficient production methods, as well as increased competition among manufacturers.

In addition, many governments around the world are providing incentives for consumers who purchase electric vehicles, further reducing the overall cost. With this continued decline in cost, it’s no surprise that the electric vehicle market is expected to see significant growth in the coming years. In fact, according to a recent report by Allied Market Research, the global electric vehicle market is expected to reach $80

81 billion by 202 So, if you’re in the market for a new car, it may be worth considering an electric vehicle. Not only are they a more economical and eco-friendly option, but with the continued growth of the market, they may also provide a good investment opportunity.

Raw Material Price Fluctuations

Raw material price fluctuations are a common issue faced by businesses across all industries. In recent times, there has been a surge in cost trends for raw materials, causing a strain on the business bottom lines. This inflation in prices has been primarily caused by supply chain disruptions, changes in trade policies, and changes in consumer demand patterns.

The pandemic has further amplified the situation, as global supply chains have been hit hard by the ongoing crisis. Additionally, natural disasters like floods and storms have also contributed to these fluctuations. While businesses have been finding ways to mitigate these rising costs, it has been a challenging task.

They have been forced to increase prices or look for alternative raw materials, which can impact the quality of their products. Companies need to keep an eye on the current cost trends and adapt their strategies accordingly to ensure they remain competitive in their respective markets.

Research and Development Investments

Research and development investments have been on the rise in recent years due to the ever-changing demands of the market. Companies have been investing heavily in R&D in order to stay ahead of the curve and keep up with the competition. However, with the current cost trends, these investments have become increasingly expensive.

The costs associated with R&D have been steadily increasing, from the cost of hiring qualified professionals to the cost of new equipment and technology. This is due in part to the increasing complexity of the problems that need to be solved and the growing competition for top talent. Companies looking to invest in R&D must be prepared to spend a significant amount of money to stay competitive.

Despite the rising costs, companies are continuing to invest in R&D as a way to keep up with the changing demands of the market and ensure their long-term success.

Future Predictions

As electric cars become more mainstream, the cost to make their batteries is expected to continue to drop. Currently, the cost to make an electric car battery can vary greatly depending on factors such as the type of battery, the size of the battery, and the materials used to make it. However, industry experts predict that these costs will decrease over time as the technology improves and becomes more efficient.

In fact, some experts predict that electric car batteries could become cheaper than traditional car batteries within the next decade. This could have a significant impact on the affordability and accessibility of electric cars, making them more appealing to a wider range of consumers. As a result, we could see a significant increase in the number of electric cars on the road in the years to come.

Advancements in Battery Technology

Advancements in battery technology have been a hot topic for many years, with researchers constantly trying to find ways to improve battery performance. Looking into the future, these advancements will continue to evolve, and with new improvements, there will be more significant changes in the way we use batteries. One of the most significant predictions is that we may see fully electric cars becoming more widespread, replacing petrol and diesel-fueled vehicles over time.

Additionally, batteries will become smaller while being more powerful, making them perfect for powering smaller devices such as smartphones for longer periods without requiring to be charged as often. There have also been predictions that wearable technology will become far more advanced due to improved battery life, even leading to the creation of inbuilt batteries in clothing items. Overall, with these technological advancements, we can expect to see significant changes in the way we live our lives, with batteries playing a crucial role in our daily activities.

Reduced Manufacturing Costs

Reduced Manufacturing Costs As technology continues to evolve and advance at an unprecedented pace, we can expect to see significant reductions in manufacturing costs in the near future. The adoption of automation, 3D printing, robotics, and other advanced technologies will enable manufacturers to streamline their production processes and increase efficiency while reducing the amount of labor required. This will not only result in significant cost savings for manufacturers but will also help to address the growing demand for more sustainable, energy-efficient manufacturing practices.

With the use of cutting-edge technology comes the promise of greater precision, consistency, and speed, which will help to reduce waste and increase efficiency throughout the entire manufacturing process. As we move forward, we can expect to see even more innovative solutions emerge, which will help to drive down costs, improve productivity, and create new opportunities for growth and innovation. Ultimately, the future of manufacturing looks bright, and we can expect to see significant benefits for both manufacturers and consumers alike.

Increased Demand for Electric Cars

As the world becomes more aware of the impact we’re having on the environment, there’s been a shift in demand for electric cars. With predictions showing that the future of transportation is electric, car manufacturers are quickly responding to this growing demand. And it’s not difficult to see why – electric cars are not only better for the environment but also cheaper to operate than their gas-powered counterparts.

As battery technology continues to improve, electric cars are becoming more practical and efficient, making them a viable option for an increasing number of people. With governments offering incentives for electric vehicle purchases, we can expect to see a continued rise in demand for electric cars in the near and distant future. It’s clear that electric cars are the future of transportation, and the automotive industry is moving quickly to meet this demand.

Conclusion

In the world of electric cars, the battery is the heart and soul of the vehicle. But as with any heart and soul, it comes with a hefty cost. Making an electric car battery is no small feat, and the cost is reflective of the hard work, innovation, and technology that goes into it.

So the next time you consider buying an electric car, remember the cost of the battery and appreciate the investment that’s been made to power your ride.”

FAQs

What is the current cost of producing an electric car battery?

The current cost of producing an electric car battery varies depending on the type of battery and production location, but it generally ranges from $100 to $200 per kilowatt-hour.

What factors affect the cost of making an electric car battery?

The cost of making an electric car battery is affected by factors such as raw material costs, labor costs, manufacturing processes, and economies of scale.

How much does it cost to replace an electric car battery?

The cost to replace an electric car battery varies depending on the make and model of the vehicle and the type of battery. It can range from a few thousand dollars to over $20,000.

Will the cost of making electric car batteries decrease in the future?

It is expected that the cost of making electric car batteries will decrease in the future due to advancements in technology and economies of scale as more electric cars are produced. Some analysts predict that the cost could eventually reach as low as $50 per kilowatt-hour.