Revolutionizing the Automotive Industry: The Daimler Electric Car Battery

If you’re in the market for an electric car, then you’ve likely heard about Daimler’s new battery technology. But what exactly is it, and how does it differ from other electric car batteries on the market? In this blog post, we’ll dive into all the details of Daimler’s electric car battery and what you need to know before considering buying one. From its unique design to its impressive performance, we’ll cover everything you need to make an informed decision about Daimler’s latest innovation.

So, whether you’re a die-hard electric car enthusiast or just starting to explore the world of electric vehicles, keep reading to discover all the ins and outs of Daimler’s electric car battery.

Introduction

Daimler, the parent company of Mercedes-Benz, has been a major player in the automotive industry for decades. Recently, they have made strides in producing electric cars and developing electric car battery technology. Their goal is to create battery packs that provide exceptional performance, reliability, and safety for their customers.

To achieve this, Daimler has invested heavily in research and development to produce durable batteries that can withstand various temperatures and operating conditions. One of the cutting-edge technologies they are employing is solid-state batteries, which have higher energy density than traditional lithium-ion batteries. These advancements are necessary to meet the increasing demands for electric cars and reduce the carbon footprint of the transportation sector.

Daimler’s commitment to sustainable mobility is reflected in their efforts to develop innovative battery technology and electric cars. And with the continued evolution of their battery technology, we can expect to see more efficient and eco-friendly electric cars on the market in the coming years.

The Growing Demand for Electric Cars

As we become increasingly aware of the environmental impacts of fossil fuels, the demand for electric cars has grown substantially. With their low emission rates and lower carbon footprint, electric cars have become a popular alternative for those looking to reduce their impact on the environment. People are beginning to realize that they can make a difference in the fight against climate change by switching to electric vehicles.

As technology continues to advance, electric cars are becoming more accessible and affordable, making them a more attractive option for consumers. In fact, the demand for electric cars is projected to continue to grow in the coming years, as more people recognize the benefits of this eco-friendly mode of transportation. It’s clear that electric cars are a crucial part of the solution to our environmental problems, and the trend towards a greener future is only set to continue.

Daimler’s Response: The EQC

Daimler’s response to the growing demand for electric vehicles is the EQC. The EQC is an all-electric SUV that promises to be technologically advanced, environmentally friendly, and exceptionally luxurious. This vehicle features two electric motors, a large battery pack, and a range of up to 400 kilometers on a single charge.

The EQC also offers a comprehensive set of safety features, including automatic emergency braking, lane departure warning, and blind spot monitoring. Its interior is spacious, comfortable, and adorned with premium materials. As the electric vehicle market continues to grow, the EQC stands out as a top contender in its class.

With its excellent performance and luxurious features, it’s hard not to consider the EQC for your next vehicle purchase.

What Makes Daimler’s Electric Car Battery Stand Out?

Daimler’s electric car battery is one of the most advanced and innovative batteries in the market. What sets it apart is its ability to deliver power and energy with unparalleled efficiency. The battery is designed with a state-of-the-art lithium-ion formula that maximizes power output while minimizing weight and space requirements.

This technology allows the battery to be lighter, therefore extending the range of the vehicle. But, what truly makes this battery outstanding is its unique ability to recharge while driving. This is possible because of its regenerative braking system, which captures the kinetic energy created during braking and converts it back into energy for the battery.

This means that the battery has the potential to last longer than most conventional batteries, giving electric cars built by Daimler a significant advantage in the marketplace. The reality is that the advance in technology has made it possible for electric cars to run longer distances efficient, more eco-friendly, and easier to charge. Daimler’s electric car battery is a prime example of how utilising the latest, innovative technologies can lead to a more sustainable future for all of us.

Long-Lasting Performance

Daimler’s electric car battery stands out due to its exceptional long-lasting performance. The battery’s unique design and high-quality materials allow it to maintain its full capacity even after many years of use. This means that the vehicle’s maximum driving range remains unchanged, and drivers can continue to rely on their electric cars even after many years of use.

Unlike traditional batteries, which can lose their capacity over time and require frequent replacements, Daimler’s electric car batteries last for many years without requiring maintenance. This not only saves drivers money but also ensures that the vehicles are more environmentally friendly by reducing the number of batteries that need to be produced and disposed of. Overall, Daimler’s electric car battery is a game-changer in the industry, offering drivers unmatched long-lasting performance and reliability.

Fast Charging Technology

Daimler’s electric car battery is making waves in the industry due to its unique fast-charging technology. Unlike conventional lithium-ion batteries, Daimler’s battery is equipped with a special cooling system that allows for fast charging without causing damage to the battery cells. This is a major breakthrough, as fast charging has been known to reduce battery life and cause overheating issues in the past.

With Daimler’s electric car battery, drivers can expect to be up and running in a matter of minutes, rather than hours. This is a huge benefit for those on the go, who don’t have the time to wait around for their car to charge. Overall, Daimler’s electric car battery is a game-changer in the industry, offering unparalleled convenience and reliability to electric car drivers.

Innovative Design and Construction

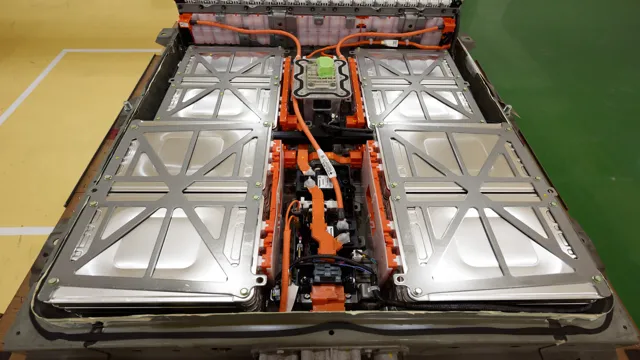

When it comes to electric cars, the battery is the heart of the vehicle. Daimler’s innovative design and construction of electric car batteries are what sets them apart from competitors. One of the main features of their batteries is their compact size, which allows for more space in the car’s design.

Additionally, Daimler’s batteries are designed for a longer lifespan than most traditional lithium-ion batteries, making them more cost-effective in the long run. The production of Daimler’s battery cells is also environmentally friendly, with a focus on reducing CO2 emissions during manufacturing. Overall, the combination of a compact design, longer lifespan, and eco-friendliness make Daimler’s electric car batteries stand out in the industry.

So, if you are in the market for an electric car, consider Daimler’s innovative battery technology for a reliable and cost-effective choice.

Environmental Impact of Daimler’s Electric Car Battery

Daimler, the German car manufacturer, has been making strides in the electric vehicle space with its battery technology. However, the production and disposal of these batteries has raised environmental concerns. The manufacturing process involves the use of rare earth metals and chemicals which have harmful effects on the environment.

Moreover, when not disposed of properly, the batteries can release toxic substances into the soil and water systems. However, Daimler has taken steps to minimize the negative impact of their batteries. They have implemented a closed-loop recycling system which involves the recovery of materials such as cobalt, nickel, and lithium from used batteries.

This initiative not only reduces environmental impact but also conserves resources, making it a win-win approach. While electric cars may offer a cleaner alternative to traditional gasoline vehicles, it’s important for companies to consider the complete lifecycle impact of their products on the environment. Ultimately, it’s up to manufacturers like Daimler to take proactive steps to minimize their impact and lead the way in sustainable practices.

Reducing Emissions and Dependence on Fossil Fuels

Daimler’s move to produce electric car batteries has a significant impact on the environment. By relying less on fossil fuels, electric cars produce fewer carbon emissions, making them a more eco-friendly option. Additionally, Daimler’s commitment to reducing the environmental impact of their battery production process is commendable.

They have implemented measures to reduce energy consumption and greenhouse gas emissions during production. As a result, their electric car batteries have a smaller carbon footprint compared to traditional gasoline-powered cars. The shift towards sustainable energy sources is crucial in reducing our dependence on non-renewable resources and mitigating the negative effects of climate change.

By supporting companies like Daimler that prioritize environmental sustainability, consumers play an active role in creating a better future for ourselves and the planet.

Sustainability Initiatives and Future Plans

Daimler, electric car battery, sustainability initiatives, environmental impact Daimler, the parent company of Mercedes-Benz, has taken several sustainability initiatives in manufacturing electric cars. In recent years, the company has paid more attention to the environmental impact of its products, including electric car batteries. While electric cars have become more popular and sustainable, their batteries pose a potential long-term risk to the environment.

Daimler aims to create electric car batteries that are sustainable and environmentally-friendly, utilizing recycled materials and renewable energy sources in the process. The company plans to make its battery production carbon-neutral by the end of 202 Moreover, Daimler intends to collaborate with other automakers to find solutions to reduce the risks of electric car batteries.

By doing so, the company demonstrates its commitment to sustainability and its impact on the environment.

Conclusion

In conclusion, the Daimler electric car battery is a revolutionary technology that is helping to reshape the future of the automotive industry. With its advanced design and cutting-edge features, this battery is providing drivers with a more sustainable and environmentally-friendly option for their transportation needs. So, if you’re ready to join the ranks of smart and responsible drivers, the Daimler electric car battery is a fantastic place to start.

Get charged up and hit the road with confidence today!”

FAQs

What is the capacity of the electric car battery used in Daimler vehicles?

Daimler electric cars come with different battery capacities, but most models have a range of around 200 to 300 miles on a single charge.

How long does it take to recharge the battery in a Daimler electric car?

The time required to recharge the battery varies depending on the charging station and the battery capacity. Using a fast charger, it can take around 30 minutes to obtain 80% of the battery charge. A standard home charger can take between 6 and 10 hours to fully charge the battery.

Is it safe to use a Daimler electric car in extreme weather conditions?

Electric cars from Daimler are designed to operate in various weather conditions, including hot and cold temperatures. The battery management system is designed to ensure the battery’s safety, performance, and durability, regardless of the weather conditions.

How sustainable are Daimler electric car batteries?

Batteries used in Daimler electric cars are designed to be long-lasting and sustainable. The company is committed to reducing its carbon footprint through the use of innovative technologies and sustainable materials in battery production and recycling.