Rev Up Your Ride with DIY 144V Electric Car Battery Pack: Everything You Need to Know

Do you dream of driving an electric car but don’t want to break the bank? Let’s face it – electric cars are expensive, and many people simply can’t afford them. But what if you could build your own electric car battery pack at home? That’s right – with a little bit of DIY know-how, you can create your very own 144V electric car battery pack that is not only cheaper than buying a new electric car but also better for the environment. Imagine driving down the highway knowing that your car is powered by clean energy that you created yourself.

You’ll not only save money on gas, but you’ll also reduce your carbon footprint. Building your own electric car battery pack may sound intimidating, but with the right tools and guidance, it’s entirely possible. Plus, the feeling of accomplishment knowing that you built your own electric car is indescribable.

In this article, we’re going to take a closer look at what it takes to build a 144V electric car battery pack. We’ll cover everything from the materials you’ll need to the steps involved in constructing your battery pack. We’ll also explore the benefits of creating your own electric car battery pack and how it can help you save money in the long run.

So, get ready to roll up your sleeves and dive into the world of DIY electric cars!

Introduction

If you’re interested in electric cars, you might consider building your own battery pack. There’s no doubt that electric cars are gaining popularity, and with good reason. They’re efficient, eco-friendly, and inexpensive to operate.

However, the high cost of purchasing a new electric car can be prohibitive for many people. That’s where DIY comes in – building your own 144v electric car battery pack can be a great option for those who want to save money and have a fun project to work on. With the right materials and a little knowledge, you can create a battery pack that will power your electric car for years to come.

By choosing the DIY route, you not only save money but also take greater control over your electric car’s performance and maintenance. So, roll up your sleeves and get ready to build an efficient, powerful battery pack that will take your electric car to new heights!

Why You Should Build Your Own Battery Pack?

As technology continues to advance, more and more people are becoming interested in building their own battery packs. While it may seem daunting at first, there are several reasons why you should consider taking on this project. First and foremost, building your own battery pack allows you to have complete control over the capacity and configuration of the battery, ensuring that it meets your unique needs.

Additionally, buying pre-made battery packs can be expensive, especially for larger applications like electric vehicles or home energy storage systems. By building your own battery pack, you can save money and customize the design to suit your specific requirements. Plus, it’s a great opportunity to learn about the inner workings of batteries and gain valuable DIY skills that can be applied to future projects.

So why not give it a try? With some research and the right tools, you can build your own custom battery pack that will power your projects for years to come.

Building Your Own DIY 144V Electric Car Battery Pack

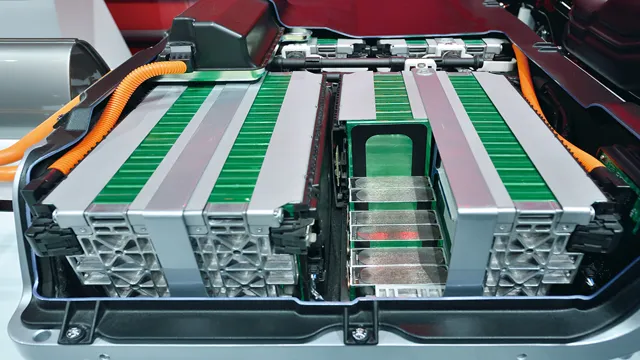

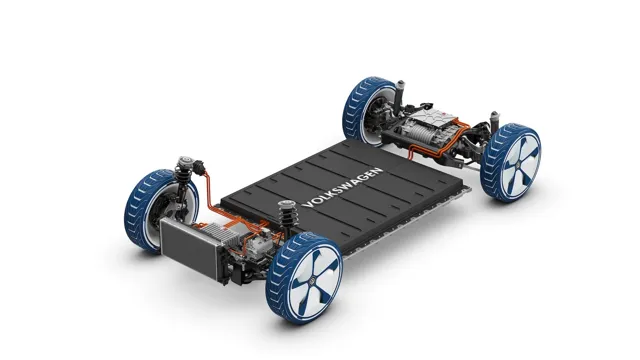

Building your own DIY 144V electric car battery pack can be an exciting but challenging project. First, you will need to gather the necessary components, which include lithium-ion cells, a battery management system, wiring, and safety equipment. Once you have everything in place, you can begin assembling the battery pack.

It’s important to follow the manufacturer’s instructions carefully and to take all necessary safety precautions to avoid any accidents. After the battery pack is assembled, you will need to test it to ensure that it’s working properly and to address any issues that may arise. Once you have completed the project, you will have a powerful and efficient battery pack that will allow your electric car to travel longer distances on a single charge.

The diy 144v electric car battery pack may require a significant investment of time and money, but the end result is well worth the effort.

Things You’ll Need

Building your own DIY 144V electric car battery pack can be an exciting project, but it does require some essential items to get started. First, you’ll need a set of lithium-ion battery cells with a total of 144V. You can find these online or from specialty stores that cater to electric car hobbyists.

Next, you’ll need a battery management system (BMS) to ensure the proper charging and discharging of the cells. The BMS helps prevent overcharging and over-discharging, which can damage the cells and pose a safety hazard. Additionally, you’ll need a battery box or case to securely hold the battery cells and the BMS.

Other necessary tools include a soldering iron, wire cutters, and wire strippers, as well as electrical tape and zip ties to keep everything organized. While building your own DIY electric car battery pack can be challenging, it’s also rewarding to see your hard work and effort come to life.

Step-by-Step Guide

Building a DIY 144V electric car battery pack may seem like a daunting task, but it is actually quite manageable with the right steps. To start, you’ll need to gather your materials, such as lithium-ion batteries, a Battery Management System (BMS), and cables. Next, you’ll want to connect the batteries in parallel and then in series, ensuring that the voltage and amperage measurements are correct.

It’s crucial to test the batteries and their connections before sealing them in a case, as any faults could be dangerous. After that, you can seal the batteries in a case and connect the BMS to regulate their charge and discharge. Finally, you can attach the battery pack to your electric car and turn it on, ready to hit the road.

With the right preparations and attention to detail, building your own DIY electric car battery pack can be a successful and rewarding project.

Selecting the Right Battery Cells

If you’re planning to build a DIY 144V electric car battery pack, selecting the right battery cells is crucial. It’s essential to choose cells that offer high energy density, endurance, and reliability. While there are several types of battery chemistries available, lithium-ion cells are the most preferred option due to their high energy density and longer lifespan.

However, not all lithium-ion cells are suitable for EV applications, so it’s crucial to consider factors such as cell voltage, capacity, discharge rate, and thermal stability before making a purchase. The most popular lithium-ion cells used in EV battery packs are Lithium Iron Phosphate (LiFePO4) and Lithium Nickel Cobalt Aluminum Oxide (NCA) cells. LiFePO4 cells are less expensive, durable, and safer, while NCA cells are more energy-dense and offer higher power.

Ultimately, the choice between the two depends on your needs and budget. It’s essential to research and compare different battery cells’ specifications before making a reliable and optimized selection.

Types of Battery Cells You Should Consider

When it comes to selecting the right battery cells for your specific needs, there are several types to consider. One option is lithium-ion batteries, which are both efficient and reliable for a variety of applications, including electric vehicles and portable electronics. Another type to consider is nickel-cadmium batteries, which are known for their durability and ability to handle extreme temperatures.

Lead-acid batteries are also a popular choice, particularly for use in vehicles and backup power systems. Ultimately, the best choice will depend on the specific needs of your project, as well as factors such as cost, lifespan, and environmental impact. By considering all of these factors, you can choose the right battery cells to ensure optimal performance and reliability for your needs.

Factors to Consider When Selecting Battery Cells

When it comes to selecting battery cells, there are a number of factors that need to be considered to ensure that you choose the right ones for your application. First and foremost, you need to consider the type of battery chemistry that will be best suited for your needs, whether it be lithium-ion, lead-acid, or nickel-cadmium. In addition to this, you should also look at the capacity, voltage, and discharge rate of the battery cells, as well as their cost and availability.

Other factors to consider include the environment in which the battery will be used, as well as any safety requirements that may be necessary. Ultimately, selecting the right battery cells can make the difference between a successful or failed application, so it’s important to take the time to make an informed decision before making a purchase.

How to Test Battery Cells

If you’re building a DIY 144v electric car battery pack, testing the battery cells is an essential step. Initially, you’ll need a digital voltmeter to check the voltage of each cell. The voltage of a fully charged cell should read around

1 volts, while a depleted cell will read around 2 volts. Additionally, you’ll need to check the internal resistance of each cell using a battery tester.

The internal resistance should be as low as possible to ensure the battery pack’s efficiency and longevity. It’s also essential to balance the cells’ voltages, ensuring that all cells are at the same level. You can use a balancing charger to achieve this.

Testing your battery cells is crucial to ensure an optimal driving experience and maximizing the life of your battery pack.

Tools Needed to Test Cells

If you’re wondering how to test battery cells, there are a few tools you’ll need. The first is a digital multimeter, which will allow you to measure the voltage of each cell. You’ll also need a battery load tester, which can apply a load to the battery to see how well it performs under heavy use.

Another useful tool is a hydrometer, which tests the specific gravity of the electrolyte in each cell to determine how well it’s functioning. It’s important to use these tools properly and follow all safety precautions when working with batteries. By testing your battery cells regularly, you can ensure they’re working at peak efficiency and catch any issues before they become major problems.

How to Test Lithium-Ion Cells

Testing lithium-ion cells is a crucial step in the battery manufacturing process. This step ensures that the cells are functioning properly and are safe to use. To test battery cells, various factors such as capacity, voltage, and internal resistance are analyzed.

Capacity refers to the amount of energy a battery can store, while voltage measures the electrical potential difference between the positive and negative terminals. Internal resistance is the resistance within the battery that affects the flow of current. By testing these factors, manufacturers can ensure that the battery cells meet the required specifications and are suitable for use in various applications.

For instance, cells that fail the test may be discarded or reworked to meet the required standards. Overall, the testing process helps to improve the performance and reliability of lithium-ion cells.

Wrapping Up

In conclusion, building a DIY 144v electric car battery pack may seem like a daunting task, but it is definitely achievable with the right tools, resources, and mindset. It’s essential to understand the technicalities of the battery pack, including the requirements of the electric vehicle in question, the type of batteries needed, and the wiring configuration. Safety should always be a top priority when dealing with high voltage systems, and care should be taken to ensure the pack is properly assembled and secured.

Regular maintenance and monitoring are also necessary to ensure the longevity and optimal performance of the battery pack. Overall, constructing a DIY electric car battery pack can be both a fulfilling and economical experience for those willing to put in the effort and commitment.

Safety Precautions

Safety precautions are essential when it comes to protecting employees and customers in any business setting. Neglecting to take the necessary steps to ensure a safe environment can lead to severe injuries and financial losses. That is why it is critical to implement safety measures such as providing safety equipment, enforcing safety protocols, and conducting routine safety checks.

Businesses must also ensure their employees are trained to recognize potential hazards and know-how to handle them properly. A single misstep can result in a costly accident that could have been avoided with proper preparation. Always remember that safety should be a top priority for any organization to ensure everyone remains safe and healthy.

Conclusion

In conclusion, it is clear that taking care of one’s mental health is of utmost importance in today’s day and age. With the fast-paced nature of our lives and the increasing demands placed upon us, it is easy to become overwhelmed and experience burnout. Mental health affects all areas of our lives, from our relationships to our careers, and it is therefore crucial to prioritize it.

This includes seeking help when necessary, practicing self-care activities, and implementing healthy coping mechanisms. By doing so, we can ensure that we are able to lead fulfilling and happy lives. Remember, taking care of yourself is not selfish, it is essential.

Conclusion

In conclusion, building a DIY 144V electric car battery pack is no small feat. It takes time, patience, and a lot of skill to put together a system that can power a vehicle. But why stop at just building a battery pack? With the right tools and knowledge, you could start a revolution and pave the way for cleaner, more sustainable transportation.

So, get those wrenches ready and let’s electrify the world, one car at a time.”

FAQs

What materials are needed to create a DIY 144V electric car battery pack?

To create a DIY 144V electric car battery pack, you will need lithium-ion cells, battery management system (BMS), nickel strips, fuses, and connectors.

How do you connect the cells together in a DIY 144V electric car battery pack?

You can connect the cells in either series or parallel depending on the voltage and capacity required for your electric car. The connection can be done using nickel strips and a spot welder.

Can you use recycled cells for a DIY 144V electric car battery pack?

Yes, you can use recycled cells from old laptops or other electronics, but the capacity and voltage of each cell must be tested before connecting them in a battery pack.

How do you maintain and extend the lifespan of a DIY 144V electric car battery pack?

To maintain and extend the lifespan of a DIY 144V electric car battery pack, you should make sure to recharge it before it’s completely depleted, avoid overcharging it, and keep it at a cool temperature (below 25 degrees Celsius). You should also regularly monitor the BMS readings to detect any potential issues.