Drive Electric: The Affordable DIY Guide to Building a 144V Car Battery Pack

Are you itching to create your own electric car? Or perhaps looking to upgrade your car to a more environmentally friendly option? Whatever your reasons may be, creating a DIY 144V electric car battery pack can be a fascinating and potentially cost-effective project. But how much will it really cost? Well, the answer is: it depends. The overall cost of creating a battery pack will vary depending on a few factors, including the quality of the materials you use, the size of the battery pack, and the tools you already have on hand.

For a DIY 144V electric car battery pack, you can expect to spend between $3,000 to $10,000 or more. It may seem like a hefty price tag, but it’s worth noting that this is significantly cheaper than purchasing a pre-made battery pack from a dealership or manufacturer. With a little bit of research and effort, creating your own electric car battery pack can be a fulfilling and satisfying experience.

Not only will it provide you with a deeper understanding of the inner workings of electric cars, but it can also save you money in the long run. So why not give it a try?

Introduction

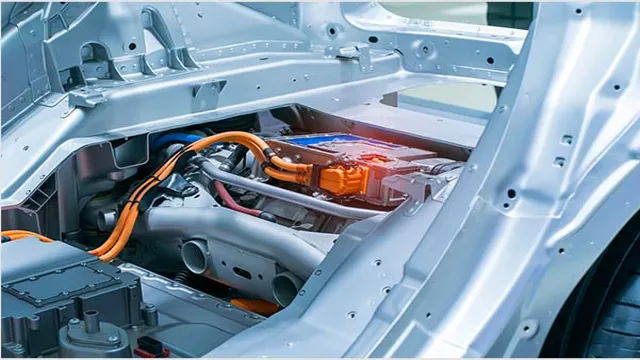

Looking to build a DIY 144V electric car battery pack? The cost may vary depending on a few factors, but it’s definitely possible to do it on a budget. You’ll need to first determine the size of the battery pack you’ll need for your car and find the appropriate batteries. Next, you’ll need to purchase a charger, balance boards, and other necessary components.

It’s important to note that safety should always be the top priority when working with high voltage systems, so proper equipment and precautions need to be taken. Overall, with some research, patience, and careful planning, building a DIY 144V electric car battery pack can be a fun and rewarding project. And who knows, it may even save you a considerable amount of money in the long run!

Breaking down the cost of a DIY 144V electric car battery pack

If you’re considering building an electric car, one of the biggest expenses is the battery pack. A common choice for DIY enthusiasts is a 144V battery pack, which provides enough power to operate most electric vehicles. However, breaking down the cost of building a high-voltage battery pack can be confusing.

There are many factors to consider, such as the type of cells, the size of the pack, the number of cells required, and the cost of additional components like a battery management system (BMS) or cooling system. While it may seem daunting, with careful planning and research, building a DIY 144V electric car battery pack can be a rewarding and cost-effective project for anyone with a bit of technical knowledge and determination.

Battery Cells

If you’re considering building your own DIY 144V electric car battery pack, the cost can vary significantly depending on the materials and components you choose. A major component of your battery pack will be the battery cells themselves, which are responsible for storing and supplying the necessary electrical energy to power your car. You’ll want to choose high-quality, reliable cells with a high energy density to ensure maximum range and performance.

Depending on the type and brand of battery cells you choose, costs can range anywhere from $2 to $10 per cell. For a 144V battery pack, you’ll need around 100 cells, bringing the total cost for just the cells alone to anywhere from $200 to $1000. However, keep in mind that shopping around for deals and buying in bulk can significantly reduce costs.

It’s also important to consider the warranty and longevity of your battery cells, as cheaper cells may need to be replaced more frequently, leading to higher long-term costs. Ultimately, investing in high-quality battery cells is a crucial step in building a reliable and efficient electric car battery pack.

Finding the best deals on high-quality battery cells for your DIY project

When it comes to DIY projects involving batteries, finding the best deals on high-quality battery cells can be a game-changer. Not all battery cells are created equal, and investing in a good-quality battery can save you a lot of time and money in the long run. So, how do you find the best deals on these battery cells? One option is to shop around online for reputable battery suppliers.

Look for reviews and ratings from previous customers to ensure that you’re getting a good product at a fair price. Another option is to buy in bulk, as this can often save you money when purchasing large quantities of battery cells at once. Whatever option you choose, always prioritize quality over cost, as a low-quality battery can ruin even the best DIY projects.

Comparing the prices of popular battery cell brands

Battery cells are an essential component of our daily lives, powering everything from smartphones to electric cars. The price of battery cells can vary significantly depending on the brand, capacity, and quality. Some of the most popular battery cell brands include Panasonic, Samsung, LG, and Sony.

Panasonic is known for producing high-quality battery cells that are used in Tesla’s electric vehicles. Their 18650 battery cell is one of the most popular cells for electric vehicles due to its high energy density and long life span. Samsung and LG are also major players in the battery cell market, producing cells for a range of applications, including smartphones and laptops.

Sony has also recently entered the market, offering high-capacity battery cells for electric vehicles. When it comes to pricing, Panasonic’s 18650 battery cell is one of the most expensive options, with prices ranging from $7 to $10 per cell, depending on the capacity. Samsung and LG both offer more affordable options, with prices ranging from $3 to $5 per cell.

Sony’s high-capacity cells can be more expensive, with prices ranging from $10 to $15 per cell. It’s worth noting that the price of battery cells can vary significantly depending on the vendor and the quantity purchased. Overall, when comparing the prices of popular battery cell brands, it’s important to consider factors such as quality, capacity, and reliability in addition to price.

Battery Management System

If you’re planning on building a DIY 144V electric car battery pack, one of the most important components you’ll need is a battery management system. This system ensures that your batteries are charged and discharged safely and efficiently, and can help prolong their lifespan. While the cost of a battery management system can vary depending on the type and brand you choose, it is generally recommended that you invest in a high-quality system to ensure the safety and reliability of your battery pack.

You may also choose to DIY your own battery management system if you have the technical knowledge and skills, which can significantly reduce costs. However, it’s important to keep in mind the potential risks of building your own system and ensure that you have adequate safety measures in place. Overall, the cost of a battery management system should be factored into your budget when embarking on a DIY electric car project.

Why a BMS is necessary for your electric car battery pack

If you’re building an electric car battery pack, it’s essential to install a Battery Management System, also known as a BMS. This system regulates the voltage and temperature of the battery cells, ensuring optimal performance and prolonging the lifespan of the battery pack. Without a BMS, the battery can overheat or discharge unevenly, leading to reduced capacity and even permanent damage.

The BMS also provides important safety features such as overcurrent protection and short circuit prevention. While some DIY enthusiasts may try to save money by skipping the BMS, it’s a critical component that should not be overlooked. Not only will a BMS help keep your electric vehicle running smoothly, but it can also prevent potentially dangerous situations from occurring.

So if you’re building an electric car battery pack, be sure to include a reliable and high-quality BMS to protect your investment.

Cost comparison of different BMS options

A Battery Management System (BMS) is an essential component of any battery system, as it helps manage and optimize the performance of the batteries. When it comes to choosing a BMS, you have various options, and the cost can vary significantly depending on your specific needs. One of the most affordable options is a basic BMS, which can cost as low as $100.

However, these basic systems may not provide the level of customization and control that you need for your battery system. On the other hand, a more advanced BMS can cost several hundred dollars or even thousands of dollars. These advanced systems provide more control and customization options, allowing you to monitor and optimize your battery system’s performance more effectively.

Ultimately, the cost of a BMS will depend on the features and functionalities you require for your specific application. It’s essential to invest in a high-quality BMS that provides the level of control and monitoring your battery system needs to perform at its best.

Other Components

When it comes to building a DIY 144V electric car battery pack, there are a few other components to consider in addition to the batteries themselves. One key component is the battery management system (BMS). A BMS is responsible for ensuring the health and safety of the batteries by monitoring their state of charge, temperature, and voltage.

It also prevents overcharging or over-discharging, and can even shut down the entire system in the event of a fault. Another important component is the charger. It’s important to choose a charger that’s compatible with both the batteries and the BMS, and that is capable of providing enough power to quickly recharge the pack.

Lastly, you’ll need various wiring, fuses, and connectors to connect all the components together in a safe and efficient manner. While the cost of these components can add up, they’re all essential for building a reliable and safe DIY electric car battery pack.

Calculating the costs of additional components, such as wiring, fuses, and connectors

When it comes to calculating the costs of additional components for your project, don’t forget to factor in components like wiring, fuses, and connectors. These may seem like small expenses, but they can quickly add up and create unexpected expenses. Wiring, for example, can be particularly costly depending on the length and type needed.

Fuses are essential to protect components in your project, but make sure you consider the cost of purchasing and replacing them over time. Additionally, connectors can sometimes require special tools or hardware to install, which can further add to the cost. While these components may seem like small details, taking the time to factor them into your budget can help you avoid any unpleasant surprises down the road.

So make sure to plan accordingly and consider all the little costs that can come with building the perfect project.

Conclusion

In conclusion, building your own 144v electric car battery pack can be both a cost-effective and rewarding experience. While the initial investment may seem steep, the long-term savings and knowledge gained from the project make it worth the effort. Plus, you’ll have the bragging rights of telling others that you didn’t just drive an electric car, you built it yourself!”

Tips for keeping costs low while still achieving high-quality results

When it comes to keeping costs low while achieving high-quality results, there are a few other components to consider beyond just the materials and labor. One important factor is the equipment being used. Investing in high-quality equipment upfront may seem like a larger cost, but it can save money in the long run by reducing the need for repairs and replacements.

Another aspect to consider is the design of the project. By working closely with your team and optimizing the design for efficiency and functionality, you can prevent costly mistakes and re-dos down the line. Additionally, maintaining open communication with contractors and suppliers can help prevent miscommunications and delays, which can also add additional costs.

By prioritizing these other components, you can keep costs low without sacrificing quality.

FAQs

How much does it cost to build a DIY 144V electric car battery pack?

The cost of building a DIY 144V electric car battery pack varies depending on the materials used and the size of the battery pack, but it can range from around $5,000 to $10,000 or more.

What materials do I need to build a DIY 144V electric car battery pack?

The materials needed to build a DIY 144V electric car battery pack typically include lithium-ion battery cells, a battery management system (BMS), wiring, and a battery enclosure.

How do I determine the size of the battery pack I need for my electric car?

The size of the battery pack you need for your electric car will depend on a few factors, including the weight of your vehicle, your driving range needs, and the power requirements of your electric motor. It’s best to consult with a professional to determine the appropriate size for your specific vehicle.

Can I use recycled battery cells in my DIY 144V electric car battery pack?

While it is possible to use recycled battery cells in a DIY 144V electric car battery pack, it’s important to note that this can be risky as the cells may not perform as well or have a shorter lifespan. It’s recommended to use new and high-quality battery cells for optimal performance and safety.