Rev Up Your Ride: Navigating the World of DIY Electric Car Lithium Batteries

Thinking about making the switch to an electric car but overwhelmed by the high costs associated with purchasing one? Fear not, because building your own DIY electric car with lithium batteries may be just the solution you’re looking for. Not only is it a fulfilling and hands-on project, but it can also save you money in the long run. However, before you dive into this exciting endeavor, it’s important to understand the ins and outs of lithium batteries and how they can power your vehicle.

In this blog post, we’ll explore everything you need to know about DIY electric car lithium batteries, from their benefits to their potential drawbacks, so that you can make an informed decision about whether this is the right path for you.

Introduction

Thinking about converting your gas-powered car into an electric one but don’t want to break the bank? One cost-effective solution is to use lithium batteries for your DIY electric car project. These batteries are widely available, reasonably priced, and have a longer lifespan compared to other types of batteries. They are also lighter and more energy-efficient, making them an ideal choice for electric vehicles.

That said, installing lithium batteries in your DIY electric car requires a solid understanding of the electrical system and safety precautions, especially when dealing with high voltage. It is recommended to seek professional help or guidance before starting your DIY electric car project. With proper planning, installing lithium batteries in your electric car can be a fun and rewarding DIY project that can save you money in the long run.

Why Choose Lithium Batteries for Electric Cars?

When it comes to choosing the best battery for your electric car, lithium batteries are the most popular choice on the market today. Why? Lithium batteries offer a range of benefits that make them the superior choice for electric car owners. First and foremost, they are incredibly lightweight compared to other battery technologies, which means they don’t add extra weight to your car, reducing its overall energy efficiency.

Additionally, lithium batteries can store a large amount of energy and recharge quickly, meaning you can get back on the road without long wait times. With their long lifespan and low maintenance requirements, lithium batteries are a smart investment for electric car owners. So if you’re looking for a reliable and efficient power source for your electric car, look no further than lithium batteries.

Advantages of Building Your Own Lithium Battery Pack

Building Your Own Lithium Battery Pack Building your own lithium battery pack can have numerous advantages. Firstly, creating your own battery allows you to customize it to suit your individual needs, making it the perfect fit for your specific application. You also have the freedom to control the quality of the components used, ensuring that the battery pack is made up of the highest quality materials.

This ultimately leads to a longer lifespan for the battery as well as increased performance and efficiency. Additionally, building your own battery pack can be a more cost-effective option in the long run, especially for those who need large or custom battery packs, as purchasing pre-made batteries can be more expensive. Finally, having the knowledge and ability to build your own battery pack can be a valuable skill to have, especially for those in the tech industry.

With so many benefits, it’s no wonder that building your own lithium battery pack is becoming a popular choice among many tech enthusiasts and professionals.

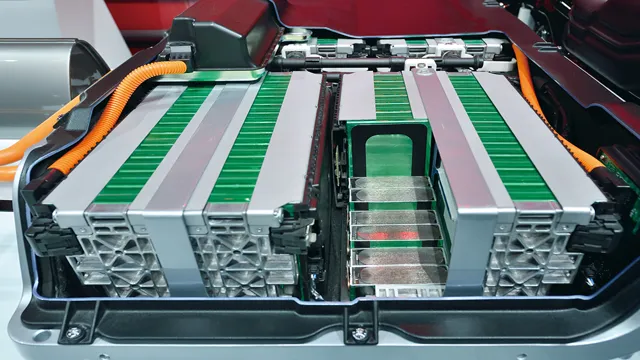

Building Blocks of Lithium Batteries

If you’re considering building your own DIY electric car, understanding the building blocks of lithium batteries is crucial for success. Lithium batteries consist of several important components, including the anode, cathode, electrolyte, separator, and collector. The anode and cathode are the positive and negative electrodes, respectively, and the electrolyte facilitates the flow of ions between them.

The separator keeps the two electrodes from touching and causing a short circuit, while the collector collects the electrical current produced by the battery. It’s important to carefully choose the quality and specifications of each of these components to ensure the performance and safety of your DIY lithium battery. With the right knowledge and tools, building your own lithium battery for your DIY electric car can be a fulfilling and rewarding experience.

Understanding Lithium Cell Chemistry

Lithium cell chemistry is the foundation of modern lithium batteries that power our smartphones, laptops, electric cars, and many other devices. At the heart of a lithium battery are two key components, the anode and the cathode. The anode is typically made of graphite, while the cathode is made of a variety of materials, depending on the specific type of battery.

When an electric current is applied to the battery, lithium ions move from the cathode to the anode, creating a flow of electrons that can be used as a source of energy. This process is reversible, meaning that it can be repeated over and over again as the battery charges and discharges. Additionally, the electrolyte solution, which typically contains lithium salts, plays a critical role in facilitating the movement of lithium ions between the anode and cathode.

By understanding the basic building blocks of lithium batteries, we can better appreciate the amazing technological advancements that have become an integral part of our daily lives.

Essential Tools and Materials Required

When it comes to building lithium batteries, there are a few essential tools and materials that are required. First and foremost, you will need a battery cell, which is the building block of your lithium battery. There are numerous types of battery cells available, each with its unique characteristics, so it’s important to choose the right one for your application.

Additionally, you’ll need a Battery Management System (BMS) that helps regulate the charging and discharging of the battery to prevent overcharging or excessive discharge. A power source, typically a charger or power supply, is also required to charge the battery. Furthermore, you’ll need safety equipment such as gloves, goggles, and a fire extinguisher as lithium batteries have the potential to catch fire or explode if not handled correctly.

Without these essential tools and materials, building a lithium battery would be quite challenging, if not impossible.

Safety Precautions When Building Lithium Batteries

When building lithium batteries, it’s important to understand the building blocks that make them up. Lithium batteries are comprised of multiple individual cells that work together to power devices. Each cell contains a positive electrode (cathode), a negative electrode (anode), and an electrolyte that acts as a conductor between the two electrodes.

These components must be carefully assembled to create a functioning battery without any defects or issues that can lead to safety hazards. It’s crucial to handle the cells with care and follow safety precautions to prevent damage or combustion. Using high-quality materials and having proper training in battery assembly are key to ensuring successful and safe production.

By paying careful attention to the building blocks of lithium batteries, and taking the necessary precautions, you can help ensure the continued growth and safety of this important technology.

Steps for Building the DIY Lithium Battery Pack

A DIY electric car lithium battery can be an alternative to expensive pre-built batteries. Before starting, it’s recommended to research, read guides, and watch videos to learn about lithium battery cells, BMS, and how to assemble them. The first step is to order the necessary components such as the cells, BMS, wiring, and casing.

Afterward, it’s important to test each cell’s voltage and capacity to ensure they’re compatible and in good condition. When assembling, it’s crucial to follow safety measures, such as wearing protective gear and working in a ventilated area. Once the components are connected, the battery pack should be charged, discharged, and balanced to ensure everything is functioning properly.

Once the pack is fully tested and operational, it can be installed in the electric vehicle. Building a DIY electric car lithium battery requires patience and knowledge, but it can save money and provide a sense of achievement.

Step 1: Acquiring Cells and BMS

The first step in building your own DIY lithium battery pack is to acquire the cells and Battery Management System (BMS). You can purchase lithium cells online, but it’s essential to ensure they are high quality and meet your project requirements. Research the capacity, voltage, and electrical characteristics you need, and make sure you purchase the same type of cell to ensure they can be charged and discharged together effectively.

With the cells in hand, the next step is to acquire a BMS. This important piece of equipment will help you monitor the battery’s status, protect against overcharging, and balance the cells’ voltage levels. It’s essential to ensure that the BMS you purchase matches the number of cells in your pack and can handle the maximum voltage and current required.

Taking the time to carefully source your cells and BMS will ensure a smooth and safe build of your DIY lithium battery pack.

Step 2: Testing Cells

When building a DIY lithium battery pack, testing cells is a crucial step to ensure safety and performance. To begin testing cells, it’s essential to select a battery tester that can measure the voltage and capacity of each cell accurately. It’s vital to test each cell individually to identify any defective or damaged cells.

Before testing, ensure that each cell is at the same state of charge. Once the tester is connected to the cell, observe the voltage and capacity readings. If any cell shows a significant deviation from the average reading, remove it from the pack and replace it with a new cell.

Testing each cell in your DIY battery pack not only ensures safe operation but also improves its efficiency and enhances its battery life. Don’t skip this step!

Step 3: Building the Battery Pack

Building your own DIY lithium battery pack can seem like a daunting task, but with the right steps, it can be a satisfying and rewarding experience. Once you have chosen the right cells and gathered the necessary tools, it is time to begin building the battery pack. First, you will need to arrange the cells in series or parallel configurations, depending on your power needs.

Be sure to use caution when soldering the cells together and keep the heat as low as possible to prevent damage to the cells. After assembling the cells, use a BMS or battery management system to balance the voltage and monitor the pack’s temperature. This will ensure optimal performance and prevent overheating or overcharging.

Finally, encase the battery pack in a protective enclosure to prevent damage and expose the charging port and power outputs. With these steps, you will have built your own functional and efficient lithium battery pack that is ready to power your projects.

Conclusion

In today’s world, where sustainability and eco-friendliness have become paramount concerns, DIY electric car lithium batteries are the perfect solution for environmentally conscious drivers who want to save money and reduce their carbon footprint. By building their own DIY electric car lithium batteries, drivers can enjoy the benefits of a low-cost, low-emission vehicle that not only saves money on fuel costs but also helps to preserve the planet for future generations. So, whether you’re a seasoned mechanic or just a curious DIY enthusiast, why not take the plunge and build your own DIY electric car lithium battery – it’s the smart and eco-friendly choice for the modern driver!”

FAQs

How do I build a DIY electric car using lithium batteries?

Building a DIY electric car with lithium batteries can be a challenging project. You will need to start by researching and buying the right type and size of lithium batteries for your car. You will also need to have some knowledge of electrical wiring and engineering to design and install the battery system and connect it to the car’s motor and other components. It’s important to follow all safety guidelines and get professional help if needed.

What are the advantages of using lithium batteries in electric cars?

Lithium batteries offer several advantages over other types of batteries for electric cars. They have a high energy density, meaning they can store more energy in a smaller space, which makes them ideal for use in electric cars. They also have a longer lifespan and are more efficient than other types of batteries. Additionally, they are lighter and more environmentally friendly than lead-acid batteries, which are commonly used in traditional cars.

How long do lithium batteries last in an electric car?

The lifespan of lithium batteries in an electric car can vary depending on several factors, including the quality of the batteries, how they are used and maintained, and the type of car and motor they are powering. Generally, lithium batteries can last anywhere from 5 to 10 years or more, depending on the above factors. It’s important to follow all maintenance and charging guidelines to ensure the longevity of the batteries.

Can I replace my lead-acid batteries in my electric car with lithium batteries?

Yes, it is possible to replace lead-acid batteries in an electric car with lithium batteries. However, it’s important to ensure that the lithium batteries you are using are compatible with your car and motor system, and that you have the proper knowledge and tools to install them safely. It’s also important to consider the cost and potential for additional upgrades or modifications that may be required to switch from lead-acid to lithium batteries.