Revamp Your Child’s Ride with DIY Electric Car Power Wheels Battery: The Ultimate Guide

Are you looking for a fun DIY project to do with your kids that will teach them about electricity and engineering? Look no further than the DIY Electric Car Battery: Power Wheels Edition! This project involves taking a standard Power Wheels car and upgrading it with a powerful electric battery that will give it more speed and power than ever before. With just a few simple tools and some basic knowledge of electronics, you can have your kids cruising around in style in their own custom electric car in no time! So why wait? Let’s dive in and learn how to build a DIY Electric Car Battery: Power Wheels Edition!

Why Make a DIY Electric Car Battery?

Making a DIY electric car power wheels battery may seem like a daunting task, but it has numerous benefits that make it worth considering. Firstly, it’s a cost-effective option that allows you to save money in the long run. Instead of buying a new battery every time your power wheels run out of juice, you can make your own and simply recharge it when needed.

Additionally, by making your own battery, you have control over the quality of materials used and can tailor its specifications to fit your power wheels’ needs. This means you can customize the battery’s voltage, capacity, and size to ensure optimal performance and longer run times. Moreover, making a battery from scratch can be a fun and educational project to engage in with friends or family while honing your DIY skills.

Overall, creating a DIY electric car power wheels battery is a cost-effective, customizable, and rewarding alternative to buying pre-made batteries. So, why not give it a try?

Save Money on Expensive Replacement Batteries

Making a DIY electric car battery might seem like a daunting task, but it can actually save you a lot of money in the long run. When it comes time to replace the battery in your electric car, it can be a costly expense. But with some basic knowledge and a little bit of effort, you can create your own electric car battery and save yourself hundreds or even thousands of dollars.

Additionally, making your own battery can give you a sense of satisfaction and control over your car’s maintenance. You can choose the specific components and materials that go into the battery, ensuring that it’s made to your exact specifications. So why not give it a try and see how much money you can save in the process?

Control Over Battery Life & Performance

Making a DIY electric car battery is an excellent way to have more control over your car’s battery life and performance. Electric car batteries need to be replaced every few years, which can be expensive. However, by creating your own battery pack, you can control the quality of the batteries used, resulting in a longer lifespan for your car’s power source.

Additionally, you can customize the battery’s configuration to optimize performance for your particular needs. This can result in increased range or quicker acceleration, depending on your preferences. When considering a DIY electric car battery, it’s essential to ensure that you have the necessary knowledge and expertise to do so safely.

However, with the right preparation and research, it can be a rewarding project with significant long-term benefits.

Materials & Tools You’ll Need

If you’re looking to convert your child’s Power Wheels into an electric car then you’ll need a few materials and tools. The most important item would be a DIY electric car power wheels battery. You can purchase a pre-made battery, but a DIY option would allow you to customize the size and capacity to fit your specific needs.

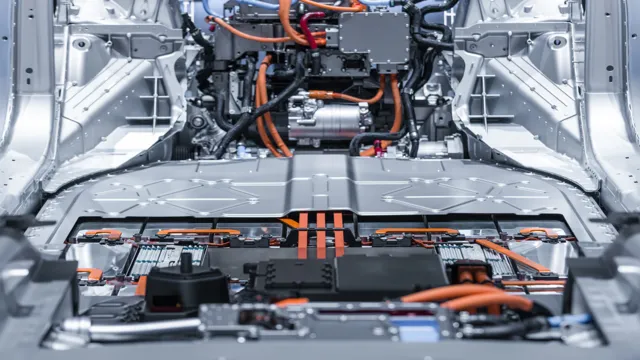

A lithium-ion battery pack is a popular choice for its high energy density and ability to hold a charge for a long period of time. You’ll also need a charger for your battery, making sure to match the voltage and amperage to your battery. Other materials include an electric motor, motor controller, wiring, and connectors.

Depending on your skill level, you can choose to purchase a kit or source individual parts. Basic tools such as a drill, screwdriver, wire stripper, and pliers will be necessary for assembly. Once you have all your materials and tools, you can begin building your electric car power wheels and watch your child’s face light up with joy as they ride around in their new, eco-friendly ride.

High Capacity Lithium Ion Battery

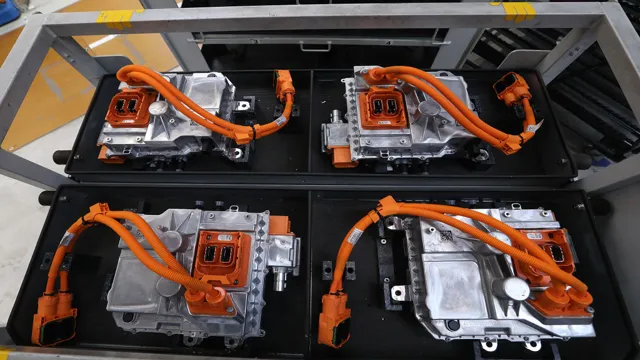

If you’re planning on building a high capacity lithium ion battery, there are a few key materials and tools that you’ll need to have on hand. First and foremost, you’ll need the battery cells themselves, which you can purchase online or from a specialized supplier. You’ll also need a battery management system (BMS) to regulate the battery’s charging and discharging, as well as a suitable enclosure to house everything.

Additionally, you’ll need wiring, connectors, and an appropriate charger for the battery. It’s important to note that building a lithium ion battery can be dangerous if proper safety precautions aren’t taken, so it’s best to work with an experienced builder or to thoroughly research the process before getting started. With the right materials and tools, however, you can create a high capacity lithium ion battery that’s perfect for powering all sorts of projects and applications.

Battery Protection Circuit Board

The Battery Protection Circuit Board (BPCB) is an essential component in any electronic device that utilizes a rechargeable battery. For those who are familiar with electronics, creating your own BPCB can be an exciting task. However, before getting started, you should ensure you have all the necessary materials and tools to complete the job.

You will need a PCB design software, a drill and bit set, copper clad board, a soldering iron, resistors, capacitors, and protection ICs. Designing a BPCB may seem challenging, but with the right tools, you can create a custom board tailored to your specific needs. The trick is to carefully follow instructions, be patient, and take your time to ensure you get it right the first time.

By doing so, you will have a reliable BPCB that will protect your batteries and safeguard your electronic devices.

Battery Management System

When it comes to building a battery management system, there are certain materials and tools that you will need to have on hand. Firstly, a microcontroller or an arduino board will be required as the central processing unit. This will be responsible for monitoring data from the battery cells and sending commands to the charging circuit.

You will also need a voltage sensor to measure the battery voltage, a temperature sensor to monitor the temperature of the battery, and a current sensor to measure the current being drawn from or supplied to the battery. In addition, a relay module, LEDs, and resistors will be needed for communication and feedback purposes. It is also important to have a soldering iron, solder wire, and a breadboard to connect the components together.

With the right materials and tools, you can build a functional and efficient battery management system that ensures the long-term health of your battery.

Charger & Power Supply

When it comes to making a charger and power supply, there are a few materials and tools that you’ll need. Firstly, you’ll need a transformer to convert the AC power to DC power. You can use a step-down transformer if you want to convert high voltage AC to low voltage DC.

You’ll also need capacitors, resistors, and LEDs to regulate the voltage and current flow. It’s recommended to use a breadboard to build the circuit before assembling it on a PCB board. Other materials you may need include heat sinks, diodes, and transistors.

As for tools, you’ll need a soldering iron, a multimeter to measure voltage and current, wire cutters, and pliers. It’s important to have a steady hand and strong focus as soldering small components can be a delicate and precise process. With the right materials and tools, you can create a custom charger and power supply that aligns with your specific needs.

Step-by-Step Guide

Are you looking to upgrade your child’s Power Wheels toy car into an electric vehicle? It’s easier than you may think! With just a few simple steps and some basic tools, you can convert the battery-powered car into a DIY electric car. First, you’ll need to purchase a 12-volt deep-cycle battery that is compatible with your Power Wheels model. Next, remove the old battery and disconnect the wiring.

Then, create a frame to mount the new battery onto the car and connect the wiring properly. Finally, test the new battery to make sure everything is working correctly. With your newly converted electric car, your child will have even more fun driving around the neighborhood or backyard.

Remember to always supervise your child during playtime and follow proper safety precautions when working with electricity.

Removing the Old Battery & Wiring

When it’s time to replace the battery on your car, truck, or boat, the first step is to remove the old battery and its wiring. This process can seem daunting, but with the right tools and a step-by-step guide, it can be a breeze. The first thing you need to do is ensure that the engine is turned off and the key is out of the ignition.

Then, locate the battery and identify which cables are positive and negative. You can usually tell by the color, with red being positive and black being negative. Use a wrench or pliers to loosen the nut or bolt holding each cable in place, starting with the negative cable.

Once both cables are loose, gently remove them from the battery terminals. With the cables removed, you can now remove the old battery from its bracket or holder. Lift it out carefully, being sure not to spill any acid or battery fluid.

Your old battery is now removed, and you’re ready to install the new one.

Preparing the Lithium Ion Battery

When it comes to preparing a lithium-ion battery, safety should always be your top priority. Before you begin, make sure you have all the necessary tools and equipment, including safety glasses, gloves, and a fire extinguisher. The first step is to fully charge the battery.

It’s important to do this before any modifications or maintenance to ensure the battery is at its highest capacity. Next, disconnect the battery from any device or equipment it may be connected to. Once the battery is fully charged and disconnected, you can begin cleaning the exterior.

Use a damp cloth to remove any dirt or debris from the casing. Avoid using any abrasive materials or chemicals that could damage the battery. With the exterior cleaned, you can move onto inspecting the battery for any signs of damage or leakage.

If you notice any defects or issues, do not attempt to use or repair the battery and dispose of it properly. By following these steps, you can ensure a safe and properly prepared lithium-ion battery for your project or device.

Installing the Protection Circuit Board & BMS

Installing a Protection Circuit Board and BMS in your electronics project can be a bit of a challenge, but with the right approach, it’s not too difficult. First and foremost, make sure you select a circuit board and BMS that are compatible with your battery and device. Next, connect the BMS to the battery according to the manufacturer’s instructions.

Once the BMS is connected, attach the protection circuit board, ensuring that it is securely affixed without any loose connections. Finally, test the circuit board and BMS to ensure that your project is protected against overcharging, over-discharging, short circuits, excess current, and overheating. By following these steps, you can rest assured that your electronics project will function safely and reliably.

Remember, safety first!

Connecting the Battery to the Power Wheels

Connecting the battery to the power wheels is a crucial step before your kid can enjoy driving their toy car. Here is a step-by-step guide to make this process easy for you. Firstly, locate the battery compartment on the power wheel.

Next, open the compartment lid and take out the old battery if it’s already there. Now, slide the new battery into the same compartment while ensuring that the wires are facing the right way. The next step is to connect the wire terminals to the right sockets while ensuring that the positive and negative sides are in the correct order.

After you’ve made all the connections, carefully tuck the wires away from the battery and close the compartment lid. Lastly, charge the battery before use and ensure that it’s functioning correctly before your kid jumps into their new ride. Always remember, safety first! It’s important to only use the recommended battery size and to follow all safety instructions when charging and handling batteries to keep everyone safe.

Charging Your DIY Electric Car Battery

If you’ve completed building your DIY electric car, the next step is to charge the battery. Although the process may seem daunting, it’s actually quite simple if you follow a few key steps. First, ensure that your charging station is compatible with your battery type and that it’s safely installed.

Then, connect the charging cable to both the station and your car, being sure to check that the connection is tight. Once the charging process begins, monitor the battery’s temperature and voltage to ensure that it’s charging correctly. You may also want to plan ahead by scheduling your charging sessions during off-peak hours, as this can save you money and provide a more reliable charge.

It’s also important to note that regular battery maintenance, such as cleaning and monitoring its health, can increase its lifespan and performance. By following these steps and staying informed about your battery’s needs, you’ll be able to keep your DIY electric car running smoothly for years to come.

Safety First: Precautions & Tips

If you’re planning to build a DIY electric car power wheels battery, there are important safety precautions you should take to ensure your project is both successful and free from hazards. For starters, make sure you have a suitable workspace that is well-ventilated and free from flammable materials. Before you start working on your battery, make sure to wear proper safety equipment including gloves, goggles and a face mask.

When working with batteries, be sure to handle them with care, as they can be dangerous if not handled properly. Also, only use chargers that are specifically designed for your battery, as using the wrong charger can cause the battery to overheat and potentially explode. Additionally, always keep an eye out for any signs of damage or wear and tear on your battery, and replace it immediately if you notice any issues.

Remember, safety is paramount when working with electronics, so always take the necessary precautions to ensure a successful and safe project.

Proper Handling & Disposal of Lithium Batteries

Lithium batteries have become ubiquitous in our daily lives, powering everything from smartphones to electric cars. However, these batteries can be dangerous when handled improperly. To ensure safety when handling lithium batteries, it’s important to take some precautions.

First, never puncture or crush a lithium battery, as it can lead to a chemical reaction that could result in a fire or explosion. When storing lithium batteries, keep them in a cool, dry place and away from flammable objects. When it comes to disposing of them, always follow your municipality’s guidelines and never dispose of them in the trash.

Recycling is the best option, and many electronics stores offer battery recycling services. By taking these precautions and properly disposing of lithium batteries, we can stay safe and help protect the environment.

Avoiding Short Circuits & Overcharging

When it comes to charging your electronic devices, it’s important to prioritize safety to prevent short circuits and overcharging. Short circuits occur when the electrical current takes an unintended path, which can cause damage to your device or even start a fire. Overcharging, on the other hand, can cause your battery to overheat and potentially explode.

To avoid these risks, always use the charging cable and power adapter that came with your device. Using third-party cables and adapters may not be compatible and could damage your device. Additionally, avoid charging your device on flammable surfaces, and never leave it unattended while charging.

By taking these precautions, you can ensure a safe and efficient charging experience for your electronic devices.

Conclusion: Experience the Power of a DIY Electric Car Battery

In conclusion, building your own electric car using Power Wheels and a battery is not only a fun and rewarding DIY project, but it is also a practical and environmentally friendly solution. Not to mention, you’ll be the coolest parent at the park with a mini Tesla-esque car for your child. So, let’s give petrol-guzzling, loud and polluting rides the boot, and embrace the power of DIY electric vehicles – it’s the way of the future!”

FAQs

How do I convert my power wheels into an electric car?

To convert your power wheels into an electric car, you will need to purchase a DIY electric car conversion kit. These kits usually come with a battery, motor, and controller that can be installed onto your power wheels to turn it into an electric car.

What type of battery do I need for a DIY electric car conversion?

For a DIY electric car conversion, you will need a deep cycle battery with a high capacity. A popular option is the lithium-ion battery, as it provides long-lasting power and is more efficient than traditional lead-acid batteries.

How long does it take to charge an electric car battery for a DIY conversion?

The charging time for an electric car battery will depend on the battery’s capacity and the type of charger used. It can take anywhere from a few hours to overnight to fully charge the battery.

Can I use a solar panel to charge the battery for my DIY electric car?

Yes, you can use a solar panel to charge the battery for your DIY electric car. This will require a solar panel, charge controller, and an inverter to convert the solar energy into electrical energy that can be stored in the battery.