Revolutionizing the Automotive Industry: The 12 Volt Electric Car Battery that Packs a Punch at 688 kg

The race for electric cars with longer ranges and better performance is on, and a heavyweight champion has emerged: the 688 kg 12V battery. This mammoth battery can power electric cars for up to 600 miles on a single charge, making it perfect for long-distance road trips without the need for frequent recharging stops. But what sets this battery apart from the rest? Why is it considered the best in the market? In this blog, we’ll dive into the technology behind the 688 kg 12V battery and explore its impressive features that make it the ultimate game-changer for electric vehicles.

So buckle up, and let’s see what makes this battery a heavyweight champion.

What is a 12V Battery and Why is it Important?

When it comes to electric cars, the 12V battery is often overlooked, but it plays a crucial role in keeping the vehicle running smoothly. This battery is responsible for powering all the electronic components other than the electric motor, such as the lights, dashboard displays, and audio system. In fact, the 12V battery in an electric car can weigh as much as 34 kilograms, contributing to the vehicle’s overall mass.

Despite its smaller size, the 12V battery is just as important as the larger lithium-ion battery in electric cars. Without it, the vehicle’s essential systems would not work, leading to a potentially dangerous situation. So, while it may not get as much attention as the more prominent components of an electric car, the 12V battery is a vital part of the vehicle that should never be overlooked.

Understanding the Basics of an Electric Car

When it comes to electric cars, many people overlook the role of the 12V battery. Unlike the main battery that powers the electric motor, the 12V battery is responsible for powering the auxiliary systems in the car, such as the lights, infotainment system, and air conditioning. Think of it as the backup battery that ensures that your car’s electronic systems remain operational even when the main battery is drained.

In addition to providing backup power, the 12V battery is also important for initializing the car’s main system. When you first turn on the car, the 12V battery sends a signal to the main battery, telling it to activate the electric motor. Without the 12V battery, the electric motor wouldn’t be able to start, and the car wouldn’t be able to move.

Overall, the 12V battery may be small in size, but it plays a crucial role in the functioning of your electric car. So, the next time you start your car, take a moment to appreciate the importance of this often overlooked component.

Advantages of a 12V Battery in Electric Cars

A 12V battery is an essential component of an electric car’s overall power system. It serves as a backup to the main battery and ensures that critical electronic systems, such as the lights and radio, continue to function even when the car is turned off. It also provides power to various components, including the power steering and brake system, which rely on the battery for their operation.

The 12V battery is typically less expensive than the main battery, making it an affordable option for car manufacturers. Having a 12V battery in an electric car also adds an additional layer of safety in case the main battery fails. In summary, the inclusion of a 12V battery in an electric car is important as it improves the overall functionality and safety of the vehicle.

The Challenge of the 688 kg 12V Battery

Electric cars have been gaining traction over the past few years as the world becomes more environmentally conscious. However, one of the biggest challenges that electric car manufacturers face is the sheer weight of the batteries. The 12V battery is one of the most significant contributors to the overall weight of the car, weighing in at a whopping 688 kg.

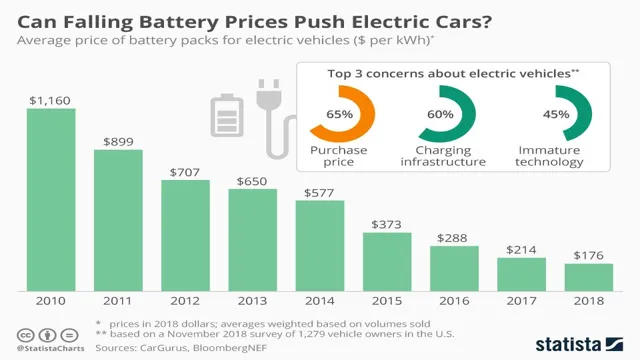

This mass can make it difficult to construct a car that is both lightweight and long-lasting. To solve this issue, manufacturers are exploring alternative battery technologies, such as solid-state batteries. These batteries have the potential to be lighter and more efficient, making electric cars a more practical and feasible mode of transportation in the future.

For now, though, the challenge remains to create an electric car that is both environmentally friendly and practical, despite the burden of the 12V battery.

Why the 12V Battery in Electric Cars is So Heavy

Electric cars are becoming increasingly popular, but with all their benefits, there’s one major challenge that manufacturers still need to overcome: the weight of the 12V battery. Weighing in at nearly 688 kg, this battery is much heavier than the standard battery found in gasoline-powered cars. This is partly due to the fact that electric cars need much more power to drive, which requires a larger battery.

However, in addition to providing power for the vehicle’s motor, the 12V battery also powers other systems like lighting, air conditioning, and infotainment. This means that the battery needs to be able to handle a lot of different functions at once. Manufacturers are constantly looking for ways to reduce the weight of the 12V battery without sacrificing performance, but in the meantime, it remains one of the biggest challenges facing the electric car industry.

The Impact of Heavy Batteries on Electric Car Performance

When it comes to the performance of electric cars, the weight and size of the batteries play a critical role, causing significant challenges in several areas. One such challenge is the heftiness of the 688 kg 12V battery. This battery is essential to electric vehicles as it powers the electric motor that drives the car.

The issue is that its weight causes reductions to acceleration, range, and overall speed, leading to a less effective driving experience. Additionally, the battery requires big amounts of power to charge, necessitating a comprehensive charging infrastructure. While technological advancements have led to lighter battery construction, the performance of electric vehicles still significantly relies on battery design.

The challenge before us is to continue innovation in battery technology, with lighter, better-performing, and sustainable batteries with higher energy density to enhance electric car performance.

Alternative Solutions to Heavy 12V Batteries in Electric Cars

Electric cars are the future of sustainable transportation, but they face a challenge in the form of heavy 12V batteries. The average weight of a 12V battery used in an electric car is around 688 kg, which is a significant amount to carry around. Alternative solutions to this issue include using smaller, lightweight lithium-ion batteries that can be distributed throughout the car.

These batteries can power the car’s lighting, electronics, and air conditioning systems, reducing the load on the 12V battery. Another solution could be to use supercapacitors, which can quickly charge and discharge electricity, making them ideal for short trips in electric cars. Additionally, regenerative braking can help to reduce the load on the battery by recharging it when the car is slowing down.

All these alternative solutions can help electric cars become more efficient and environmentally friendly without compromising on performance. As the world moves towards a greener future, it is essential to explore various solutions to ensure that electric cars can become the norm.

The Future of 12V Batteries in Electric Cars

One of the challenges facing electric car manufacturers is the mass of 12-volt batteries. These batteries are necessary for running the car’s accessories and controlling the overall power system, but they add extra weight that can reduce the vehicle’s range. Currently, electric cars typically use lead-acid batteries for this purpose, which can weigh up to 50 pounds each.

However, there are efforts underway to develop lighter, more efficient alternatives to these batteries, such as lithium-ion or solid-state batteries. These new technologies could significantly reduce the mass of 12-volt batteries in electric cars, resulting in longer ranges and improved overall performance. In fact, some experts believe that the mass of these batteries could be reduced by up to 75% in the near future, which would be a major breakthrough for the electric car industry.

As electric cars continue to gain popularity, the demand for better battery technology will only increase, driving further innovation in this area.

Innovations in 12V Battery Technology for Electric Cars

12V Battery Technology for Electric Cars Electric cars are becoming increasingly popular as people move towards a more sustainable and environmentally friendly mode of transportation. One crucial component of these vehicles is the 12V battery which powers the car’s accessories such as lights, radio, and other essential systems. However, with advancements in technology and the growing need for more efficient and reliable battery options, automakers are developing innovative solutions to improve 12V battery technology.

One promising approach is the use of lithium-ion batteries, which offer higher energy density and greater resistance to extreme temperatures compared to traditional lead-acid batteries. Another potential solution is the use of supercapacitors, which can quickly charge and discharge energy and are ideal for short bursts of power needed in starting the engine or powering accessories. The future of 12V battery technology for electric cars is exciting, promising more efficient and sustainable solutions that will make these vehicles more reliable and cost-effective in the long run.

Trends in Reducing the Weight of 12V Batteries in Electric Cars

The future of 12V batteries in electric cars is one that focuses on reducing weight. As electric cars gain more popularity, reducing their weight becomes an issue of utmost importance. One way to do this is by reducing the size of the 12V batteries that power the car’s auxiliary systems.

These systems include lighting, HVAC, and infotainment systems. With improvements in technology, smaller and lighter 12V batteries are now available. Lithium-ion batteries, for example, are a good option as they are lighter and more efficient than traditional lead-acid batteries.

Car manufacturers are also investing in hybrid systems that combine a smaller 12V battery with a larger main battery, reducing the overall weight of the vehicle. These trends in reducing the weight of 12V batteries will have a positive impact on the electric car industry, making electric cars more affordable, efficient, and accessible to the masses.

Conclusion: The Role of 12V Batteries in the Electric Car Revolution

In conclusion, the 12 volt battery in an electric car may seem like a small piece of the puzzle, but with a mass of 688 kg, it packs quite a punch. This hefty battery is responsible for powering everything from the headlights to the radio, and as electric car technology advances, we can only expect these batteries to become even more impressive. So the next time you see an electric car cruising down the road, take a moment to appreciate just how much that 12 volt battery is contributing to a greener, more sustainable future.

“

FAQs

1. What is the weight of the electric car’s 12 volt battery?

The mass of the electric car’s battery pack can affect its performance by increasing its weight and reducing its overall range. 3. Is it possible to increase the range of an electric car by reducing the mass of its battery pack?

Yes, reducing the mass of an electric car’s battery pack can increase its range by decreasing the overall weight of the vehicle. 4. How does the mass of an electric car’s battery pack compare to that of a traditional gasoline-powered car?

The mass of an electric car’s battery pack is typically much heavier than that of a traditional gasoline-powered car, due to the denser energy storage required for electric vehicles.