Power Your Ride with Cobalt: The Future of Electric Car Batteries

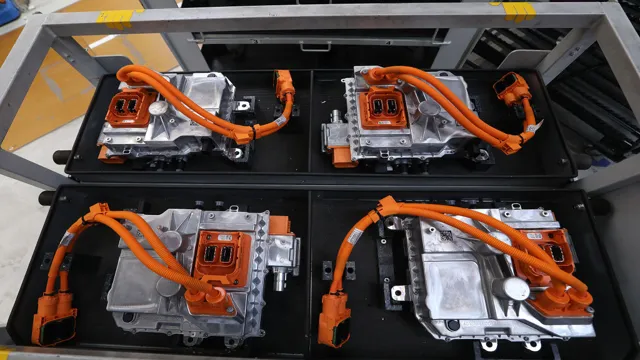

Electric cars are becoming increasingly popular as people strive to reduce their carbon footprint and rely less on fossil fuels. One crucial component of these vehicles is the battery, which must be both high-performing and long-lasting. Cobalt plays a significant role in electric car batteries, as it is used to create the cathode material that stores and releases energy.

However, there are growing concerns about the ethical and environmental implications of the cobalt mining industry, as well as the potential for supply chain disruptions. In this blog, we will explore the role of cobalt in electric car batteries, its importance, and the challenges associated with its use.

What is Cobalt?

Electric car batteries rely on cobalt, an essential element used in the production of the cathodes found in these batteries. This mineral helps to stabilize the electrical potential within the battery, allowing it to maintain a steady output of power. Despite its importance, there are concerns around cobalt sourcing due to the scarcity of the mineral and the ethical concerns around its mining practices in certain countries.

In response, some manufacturers are exploring alternative materials or new cobalt-free battery designs to reduce their reliance on this vital component. However, for the time being, cobalt remains a key component in the production of electric car batteries, and its availability will continue to play a significant role in the development of the industry.

The importance of cobalt in electric car batteries

Cobalt is a metallic element that has become increasingly important in the modern world because of its role in the manufacturing of lithium-ion batteries that are used in most electric cars. This mineral is a transition metal with a robust magnetic property that is used as a cathode in battery production. The reason that cobalt is so useful in batteries is that it helps increase the life of the battery and its overall performance.

It helps prevent battery overheating, which is crucial for electric vehicles as it can prolong the battery’s life and prevent possible catastrophes. Cobalt is also used in other industrial applications such as the production of jet engine parts, electronics, and alloys, but it’s electric car batteries that require most of the cobalt demand. The need for batteries is constantly rising as an increasing number of people switch to electric vehicles, making it a vital mineral in the safe transportation of the masses towards an eco-friendlier future.

Sources and mining of cobalt

Cobalt is a chemical element that is found in the Earth’s crust in trace amounts. It is a hard, brittle, silver-grey metal that is widely used in various applications such as batteries, jet engines, and superalloys. Cobalt is an important component of rechargeable lithium-ion batteries used in electric vehicles and smartphones.

The majority of the world’s cobalt comes from mines in the Democratic Republic of Congo (DRC). Cobalt mining in the DRC has been mired in controversy due to human rights abuses and child labor. Many companies are now looking for more responsible sources of cobalt, such as recycled batteries.

With the growing demand for electric vehicles and other clean energy technologies, the need for cobalt is only expected to increase. It is vital to find sustainable and ethical ways to mine and source cobalt to ensure its availability and minimize its impact on people and the environment.

Cobalt-Free Battery Developments

Electric cars are seen as the future of transportation, but their current batteries are still a concern for some. Cobalt, a material used in many electric car batteries, is expensive and controversial due to child labor and human rights concerns. Luckily, researchers have been making strides in developing cobalt-free batteries.

One emerging technology is the sodium-ion battery, which uses sodium instead of cobalt. These batteries are still in the development stage but have shown promising performance levels. Another option gaining traction is the solid-state battery, which replaces liquid electrolytes with a solid material, resulting in a safer and more efficient battery.

These new developments are exciting for the future of electric cars and show that the industry is committed to creating sustainable, ethical, and affordable electric vehicles.

Advantages of cobalt-free batteries

Advantages of Cobalt-Free Batteries As the world turns to renewable energy sources, battery technology has become increasingly important. One of the biggest issues with traditional batteries is the use of cobalt, which has been linked to unethical mining practices and human rights abuses. However, thanks to recent advancements in technology, cobalt-free batteries are becoming a viable alternative.

These batteries have several advantages over traditional batteries, including better safety, higher energy density, and longer lifetimes. Additionally, cobalt-free batteries are often less expensive to produce and more environmentally friendly. With these benefits in mind, it’s no surprise that many companies are starting to invest in cobalt-free battery technology.

By making the switch, they can improve their sustainability credentials and provide more reliable, cost-effective energy solutions for their customers.

Latest advancements in cobalt-free battery technology

Cobalt-free battery technology is quickly becoming a hot topic in the world of clean energy. Scientists and researchers are working tirelessly to develop innovative solutions to replace cobalt, a mineral often associated with unethical mining practices and environmental damage. With the demand for electric vehicles and renewable energy storage solutions on the rise, the need for sustainable and eco-friendly battery technology is more pressing than ever.

Fortunately, several companies have made significant progress in cobalt-free battery technology. A leading contender in this field is Tesla, which is working on a new battery design that will eliminate the need for cobalt altogether. Meanwhile, other researchers are experimenting with new materials such as nickel, manganese, and aluminum to create high-performance, sustainable batteries.

The possibilities are exciting, and it’s only a matter of time before we see the widespread adoption of cobalt-free batteries in the market.

Drawbacks and challenges of cobalt-free batteries

Developments in cobalt-free batteries are increasingly gaining traction due to concerns over the ethical and environmental implications of cobalt mining. These batteries rely on alternative metals such as nickel, manganese, and iron to provide the conductivity and stability required for effective performance. Although these developments are promising, cobalt-free batteries come with their own set of drawbacks and challenges.

For instance, the materials used may not be as efficient as cobalt in terms of energy density, which can lead to a reduction in the battery’s performance. Additionally, the production of cobalt-free batteries may require higher amounts of energy and emit more greenhouse gases than their cobalt-containing counterparts. These challenges must be addressed to ensure the mainstream adoption of cobalt-free batteries and to fully realize their potential as a sustainable and ethical alternative.

The Future of Electric Car Batteries

Electric car batteries have come a long way in the past decade, evolving from bulky and inefficient models to sleek, high-powered versions that can go for miles on a single charge. One major component of these batteries is cobalt, a metal that has traditionally been used in the cathode of lithium-ion batteries to help improve their performance. However, cobalt is expensive and has been linked to unethical mining practices that harm the environment and exploit workers.

As a result, researchers are exploring new ways to reduce or eliminate the need for cobalt in electric car batteries. Some of the potential alternatives include nickel and manganese, which are cheaper and more abundant, and solid-state batteries that use a different type of electrolyte. While there is still much research to be done before these alternatives can become widespread, the future of electric car batteries is looking bright, as companies and governments invest more resources into developing cleaner, more sustainable options.

Impact of cobalt on the future of electric car batteries

Electric car batteries have come a long way over the past decade as manufacturers strive to improve their range and efficiency. One key element that has a significant impact on the future of these batteries is the cobalt used in their production. Cobalt is a crucial component of electric car batteries as it allows them to store energy efficiently and power the vehicle.

However, the mining of cobalt has come under scrutiny due to humanitarian and environmental concerns related to its extraction. Companies are now exploring alternatives such as nickel-manganese-cobalt (NMC) batteries that use less cobalt while providing the same performance. Moreover, advancements in battery chemistry could eventually eliminate the need for cobalt altogether, setting the stage for more sustainable and ethical production of electric car batteries.

The evolution of electric car batteries will continue to be shaped by advancements in materials science and manufacturing processes, as manufacturers work to improve the efficiency of batteries and reduce their environmental impact.

Emerging battery technologies and materials

Electric car batteries have come a long way in the last decade. However, emerging battery technologies and materials are changing the game for electric cars. Lithium-ion batteries are still the most commonly used type of battery in electric cars, but innovations like solid-state batteries show great promise for improving battery efficiency, safety, and affordability.

These batteries use solid electrolytes instead of liquid ones, which allow for higher energy density and faster charging times. Other materials, such as silicon, are also being explored as a replacement for graphite in battery anodes, which can further improve battery life and performance. With these advancements in battery technology, electric cars are becoming more accessible and practical for everyday use.

The future of electric car batteries looks bright, as the industry continues to push towards more efficient, sustainable, and affordable solutions.

Conclusion

After examining the role of cobalt in electric car batteries, it’s clear that this coveted mineral holds great power. Cobalt is an essential component in the production of batteries that allow electric vehicles to run smoothly and efficiently. As a result, its demand has skyrocketed in recent years.

However, there is also growing concern surrounding the ethical and environmental impacts of cobalt mining. As we move towards a more sustainable and responsible future, finding alternative sources of cobalt and improving mining practices will become increasingly important. So, while cobalt may be the key to unlocking the potential of electric cars, we must ensure that its power isn’t at the expense of our planet and its people.

“

FAQs

How does cobalt play a role in electric car batteries?

Cobalt is an important component in the manufacturing of electric car batteries as it helps to stabilize the battery and increases its longevity.

Are there any alternatives to using cobalt in electric car batteries?

Yes, there are alternative materials being developed such as nickel and manganese, but cobalt still remains a main component due to its efficiency in the battery.

Is the mining of cobalt ethical for the production of electric car batteries?

There have been concerns about the ethical mining of cobalt, as many of the mines are located in developing countries with poor working conditions. However, efforts are being made to ensure ethical mining practices are put in place.

Can electric car batteries be recycled and how does this impact the demand for cobalt?

Yes, electric car batteries can be recycled, and this can help to reduce the demand for new cobalt. However, as the production of electric cars increases, it is likely that the demand for cobalt will also continue to increase.