Why Are Electric Car Batteries So Expensive? Exploring the High Costs of Green Energy

Electric cars have continued to rise in popularity as more people are opting for sustainable and eco-friendly modes of transportation. However, the price tag of these vehicles often includes a hefty sum for the battery. Have you ever wondered why electric car batteries are so expensive? Well, there isn’t a straightforward answer.

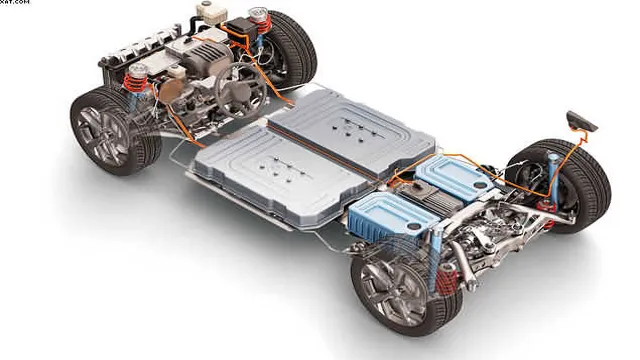

Electric car batteries are composed of expensive materials, require advanced technology to manufacture and are subject to supply and demand factors. At the heart of every electric car is the battery, which generates the power required to move the car. The most common type of battery used in electric cars is the lithium-ion battery, which has a higher energy density, allowing the car to travel further on a single charge.

However, lithium-ion batteries require rare and expensive materials such as cobalt, nickel, and lithium to manufacture. These materials are not easy to find, and their prices can fluctuate. Another factor contributing to the high cost of electric car batteries is the advanced technology required to manufacture them.

The process is complex and requires precision engineering, which adds to the manufacturing cost. In addition, the cost of research and development for electric cars is often higher than traditional combustion engine vehicles. Moreover, the supply and demand factor plays a significant role in the cost of electric car batteries.

The demand for electric cars continues to rise, and automakers need to keep up with the supply. Currently, there aren’t enough factories to keep up with the increasing demand, leading to a limited supply of batteries and driving up the costs. In conclusion, there are various reasons why electric car batteries are expensive.

The use of rare materials, advanced manufacturing technology, and supply-demand economics, all contribute to the high prices. However, the costs are expected to fall as battery technology advances, production expands, and more alternatives to rare materials are discovered.

Battery Material and Manufacturing Costs

It’s no secret that electric car batteries can be expensive. One reason for this is the cost of the materials used to make them. Most electric car batteries are made from lithium-ion, which requires a variety of rare metals such as lithium, cobalt, and nickel.

These materials are not cheap to source, and as demand for electric cars continues to grow, prices are likely to rise. Additionally, the manufacturing process for electric car batteries is complex and time-consuming, which also increases their cost. However, it’s important to note that as technology improves, the cost of materials and manufacturing is likely to decrease.

As more companies enter the market and competition increases, there may also be downward pressure on prices. Ultimately, the cost of electric car batteries is just one factor to consider when looking at the overall cost of owning an electric vehicle. Other factors such as fuel savings and tax incentives should also be taken into account.

Rarity and Price of Lithium and Other Materials

When it comes to the cost of battery manufacturing, one of the most significant factors that drive the price is the availability of the materials used to produce them. Lithium, for instance, is one of the essential materials used in battery production and makes up a considerable share of the cost. However, the rarity of other minerals and metals like cobalt, nickel, and copper also contribute heavily to the overall cost of the batteries.

These materials are not only necessary, but they are also in high demand, which can significantly impact the price. In addition, the costs of extracting and refining these materials, transportation costs and labor costs can also play a significant role. Ultimately, the cost of battery manufacturing is a complex mix of several factors, and manufacturers need to strike a balance between quality, cost, and environmental sustainability to ensure that their products are both economically and environmentally viable.

Precise Manufacturing Process and Equipment Costs

When it comes to producing batteries, the material and manufacturing costs can be quite high. It’s essential to have a precise manufacturing process to ensure that the final product is of high quality and meets the required standards. There are various factors that affect the costs involved in producing batteries, including the raw materials used, the equipment needed, and the labor costs.

The most commonly used materials in battery production are lithium, cobalt, and nickel, which are all relatively expensive. The manufacturing process for batteries is also complex, requiring specialized equipment that is costly to purchase and maintain. However, as the demand for batteries increases, the costs associated with production are likely to decrease as manufacturers develop more efficient processes and technologies.

In the end, the precise manufacturing process and equipment costs play a significant role in determining the final cost of the batteries, but as technology advances, it is expected that costs will continue to become more affordable.

R&D Costs

Electric car batteries are expensive due to high research and development (R&D) costs. Since electric vehicles are still a relatively new technology, manufacturers are continually researching and developing new battery technologies. This involves a lot of money and resources, resulting in higher production costs that are passed on to the consumer.

Additionally, the materials used to make electric car batteries, such as lithium, cobalt, and nickel, are also expensive. As demand for electric vehicles continues to rise, companies are investing even more in R&D to improve their battery technology and make them more affordable. It’s a necessary expense to keep up with the advancements in the industry and make electric vehicles a more viable option for consumers.

However, as the technology improves and more manufacturers enter the market, we can expect the cost of electric car batteries to decrease over time.

Continuous Improvement and Innovation for Better Performance

When it comes to continuous improvement and innovation, research and development (R&D) comprise a vital aspect of enhancing business performance. R&D encompasses the process of exploring new technologies, techniques, products, and services. The more novel and experimental the approach, the higher the associated costs.

These costs can be onerous for most businesses and can deter them from implementing much-needed changes for improvement. Despite this, investing in R&D is essential to the growth and sustainability of any business. Finding new ways to enhance products or services, and researching new technologies, can lead to increased efficiencies, reduced operational costs, and ultimately, increased profitability.

In today’s fast-paced world, innovation is at the forefront of companies that are successfully improving customer satisfaction and keeping ahead of the curve. It is, therefore, necessary for businesses to allocate an appropriate budget for research and development to reap the full benefits of innovation and continuous improvement.

Long-Term Research for Advanced Battery Solutions

When it comes to developing advanced battery solutions, the costs of research and development (R&D) are a major consideration. Long-term R&D efforts are necessary to create batteries that can store more energy, charge faster, and have a longer lifespan. While these advancements have the potential to revolutionize many industries, the costs involved can be prohibitive for some organizations.

However, the benefits of investing in advanced battery technology are numerous, including reduced emissions, increased efficiency, and improved reliability. As such, many companies are willing to invest in R&D to stay ahead of the curve and be at the forefront of technological progress. It’s important to note that these costs can vary widely depending on the scope and complexity of the project.

Some companies may choose to collaborate with academic institutions or other organizations to share these costs and benefit from a wider pool of expertise. Ultimately, as demand for more advanced battery solutions continues to grow, R&D efforts will play a critical role in shaping the future of energy storage.

Market Demand and Supply

Electric car batteries are often considered expensive due to the market demand and supply factors. As we shift towards green energy, the demand for electric vehicles is on the rise. However, the supply of the batteries required for these cars is limited, which leads to higher prices.

The production of electric car batteries requires a significant amount of resources, including rare earth metals, which are costly to extract and process. This raises the production cost of batteries and makes them expensive for the end-users. Additionally, the technology used in these batteries is relatively new, which contributes to the higher prices associated with electric cars.

However, as the demand for electric cars increases, manufacturers are investing more in research and development to produce batteries at a lower cost. The advancements in technology and economies of scale will eventually make electric cars more affordable for the masses.

Limited Production Capacity and High Demand

Limited Production Capacity and High Demand When it comes to the market demand and supply of a product, limited production capacity and high demand can create a challenging situation for businesses. In this scenario, demand exceeds supply, and it is a good problem to have. However, a business must be careful not to disappoint customers.

This can result in loss of market share and reputation. A business can address this challenge by improving its production efficiency, increasing production capacity, and managing inventory. Additionally, a good strategy would be to prioritize high-demand products and discontinue products with low demand.

By doing so, a business can maintain its product quality and reputation while catering to the market’s demands adequately. It is essential to find the right balance between production capacity and demand to ensure customer satisfaction and maximize profits. Overall, limited production capacity and high demand require a business to be proactive and agile in its decision-making process.

Higher Prices for High-Quality and High-Performance Batteries

As the demand for electric vehicles (EVs) continues to grow, so does the demand for high-quality and high-performance batteries that power them. This phenomenon is driven by the need for greater driving ranges, faster charging times, and longer battery lifecycles. Companies that manufacture EV batteries are investing heavily in research and development to create cutting-edge battery technologies that meet these demands.

As a result, the prices for high-quality and high-performance batteries have risen, reflecting the increased cost of production. However, the market demand for these batteries continues to be strong, and consumers are willing to pay a premium price for them. The supply of such batteries is also growing, with an increasing number of manufacturers entering the market.

Moreover, advancements in battery technology are resulting in improved energy densities and lower costs, which is making EVs more affordable and accessible to the general public. Overall, this trend bodes well for the future of the EV industry and is driving innovation and competition among battery manufacturers.

Government Incentives and Programs

Electric car batteries can be expensive, but there are government incentives and programs that can help offset the cost. For instance, in the United States, there’s the federal tax credit for electric cars, which can amount to as much as $7,500 depending on the vehicle’s battery capacity. Some states also offer incentives such as rebates, tax credits, and even access to HOV lanes to encourage the adoption of electric vehicles.

Additionally, some car manufacturers offer discounts or incentives for purchasing electric cars. While the initial cost of an electric car with a sophisticated battery might be higher, the long-term benefits of lower fueling costs and reduced environmental impact make for a compelling case. And with the government incentives and programs available, going electric is becoming more accessible and affordable for many people.

Subsidies and Tax Credits for Electric Car Manufacturers

In recent years, governments around the world have started offering incentives and programs to promote the use of electric cars, which are more environmentally friendly than traditional gasoline-powered vehicles. One of the most significant incentives that the government offers is subsidies and tax credits for electric car manufacturers. By offering these financial rewards, the government can encourage car manufacturers to develop more electric cars while also making them more affordable for consumers.

These subsidies and tax credits help to offset the higher costs of producing electric cars, as well as reducing the cost for customers who want to purchase them. As a result, more people are choosing to buy electric cars, which is helping to reduce the use of fossil fuels and limit the impact of climate change. Overall, these incentives and programs are crucial in driving the adoption of electric cars and promoting sustainable practices.

Conclusion

When it comes to electric car batteries, they say you get what you pay for – and unfortunately, that’s a high price. While the cost may seem shocking at first glance, it’s important to remember that the investment not only supports a more sustainable future, but also pays off in the long term with lower fuel and maintenance costs. So, while electric car batteries may be expensive, they ultimately spark a brighter future for both the environment and our wallets.

“

FAQs

Why are electric car batteries so expensive?

The high cost of electric car batteries is due to the materials used to make them, such as lithium-ion. Additionally, the technology for producing these batteries is still relatively new and evolving, which also contributes to the cost.

Will the price of electric car batteries decrease in the future?

Yes, as technology for producing electric car batteries improves and as demand increases, the price should decrease. Additionally, government incentives and subsidies may also make electric cars more affordable in the future.

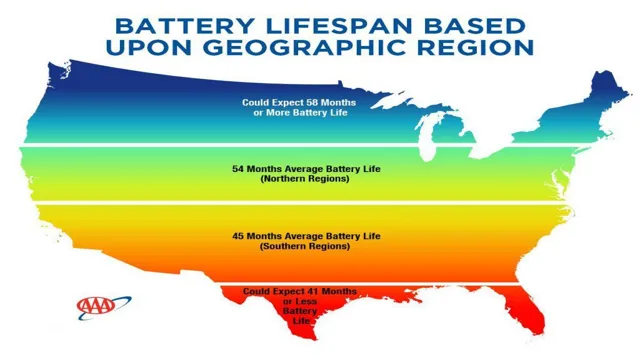

How long do electric car batteries last?

The lifespan of electric car batteries varies based on the model and use of the vehicle, but they typically last between 8-10 years. However, advancements in battery technology may result in longer battery life in the future.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. Currently, recycling rates are relatively low, but efforts are being made to improve the recycling process to make electric vehicles more sustainable and environmentally friendly.