Revolutionizing the Future: The Rise of Electric Car Batteries Manufacturing

Electric cars have become increasingly popular over the past few years, and it’s not hard to see why. They’re environmentally friendly, cost-effective, and now, thanks to advancements in battery technology, they’re more practical than ever. Batteries are essential to the functioning of electric cars, and manufacturers have been working hard to revolutionize them.

The focus has been on creating both more efficient and longer-lasting battery technology that can power cars for hundreds of miles on a single charge. One of the most exciting developments in electric car batteries is the use of lithium-ion technology. These types of batteries are lighter and more powerful than traditional lead-acid batteries, making them perfect for electric cars.

Advancements in lithium-ion battery technology mean that these batteries have longer lifetimes and are more efficient than ever, allowing electric cars to travel further on a single charge. In addition, research is being done to explore the use of solid-state batteries, which are even smaller, lighter, and have the potential to store even more energy. But battery technology isn’t just about making electric cars more practical.

It’s also about making them more accessible. As battery technology improves, the cost of manufacturing electric cars decreases, allowing more people to afford them. Additionally, the growth of charging infrastructure means that electric car owners no longer have to worry about running out of power on long journeys.

In conclusion, the rapid advancement of battery technology is revolutionizing transportation. Electric cars are becoming more practical, affordable, and sustainable, making them an attractive alternative to traditional petrol-based cars. With continued research, it’s only a matter of time before battery technology takes electric cars to the next level, making them an even better choice for drivers.

The Rise of Electric Cars

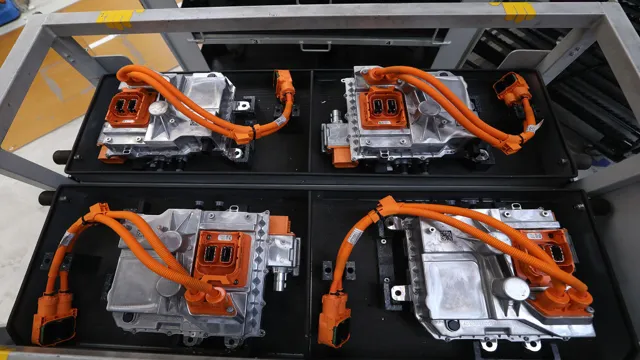

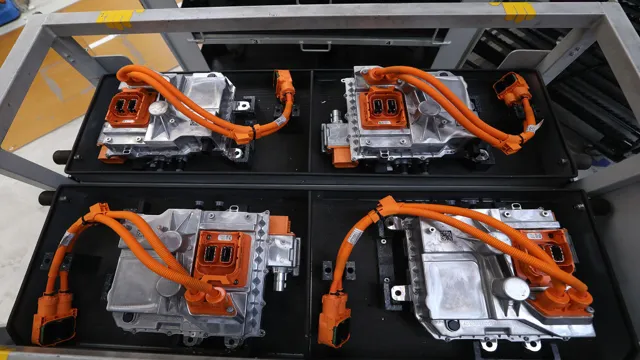

Electric car batteries manufacturing has become an increasingly important topic as the world shifts towards eco-friendly transportation. With electric vehicles (EVs) becoming more popular, the demand for efficient and long-lasting batteries has skyrocketed. The production of electric car batteries involves a complex process that requires specialized equipment, materials, and expertise.

Manufacturers must carefully balance factors such as energy density, safety, and cost-effectiveness to create the best possible product. One of the biggest challenges for the industry today is scaling up production to meet the growing demand for EVs. However, despite these challenges, advancements in technology and production methods have opened up new possibilities for electric car batteries manufacturing.

As the market for EVs continues to grow, we can expect to see even more innovation and development in this exciting field.

Statistics on Electric Car Sales

Electric car sales have significantly increased in recent years, which shows the rise of electric cars. According to the International Energy Agency (IEA), global electric car sales reached 1 million in 2019, and the number is expected to continue growing.

In fact, the IEA projects that electric car sales will hit 145 million by 2030. This rise of electric cars is due to a combination of factors, such as increased awareness of climate change and environmental concerns, government incentives, and improvements in technology. Electric cars have become more accessible and affordable, making them a viable option for many consumers.

As a result, many car manufacturers are investing in the development of electric vehicles, showing a shift toward more sustainable transportation options. The trend of electric cars is a promising sign of progress in the fight against climate change, and it is exciting to see how this industry will continue to grow and evolve in the coming years.

Environmental Benefits of Electric Cars

Electric Cars The rise of electric cars is not just an exciting trend in the automotive industry, it is also a positive step towards a greener and healthier environment. With increased awareness of the need to reduce carbon emissions and air pollution, people are beginning to see the value of electric cars. One of the biggest environmental benefits of electric cars is that they produce zero emissions.

This means that they do not release harmful pollutants into the air that contribute to climate change and poor air quality. Electric cars also rely on renewable energy sources such as solar and wind power, further reducing their carbon footprint. In addition, electric cars are also more energy-efficient than their gasoline counterparts.

As a result, they require less energy to operate and can travel longer distances on a single charge. The rise of electric cars is a promising development for the environment and the future of transportation.

The Importance of Electric Car Batteries

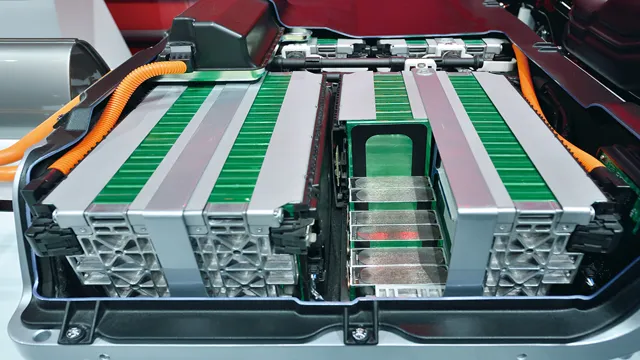

Electric car batteries manufacturing has become increasingly important as the demand for electric vehicles grows. The batteries are the heart of electric cars, enabling them to run without gas, and they are critical for achieving long driving ranges. Battery production involves the use of different materials, each of which has unique properties that impact a battery’s performance, safety, and cost-effectiveness.

Lithium-ion batteries, for instance, are widely used in electric cars because they are lightweight and can store a lot of energy. However, they require a significant amount of cobalt, which is a scarce and expensive material that raises concerns about social and environmental sustainability. To overcome these challenges, manufacturers are exploring new chemistries, such as solid-state batteries, that offer higher energy density and longer lifespans.

As the electric vehicle market continues to evolve, battery technology will play a key role in shaping its future and meeting the needs of consumers who are looking for sustainable and reliable transportation options. The development of efficient and sustainable electric car batteries will help promote the transition towards a greener future and reduce our dependence on fossil fuels.

Types of Electric Car Batteries

Electric Car Batteries Electric car batteries are the backbone of electric vehicles, providing the power that propels the car. The importance of these batteries cannot be overstated, as they determine not only the driving range of the vehicle but also its efficiency, performance, and cost. There are two main types of electric car batteries – lithium-ion batteries and solid-state batteries.

Lithium-ion batteries are currently the most popular type of electric car battery and are widely used in different types of electric vehicles. They are known for their high energy density, durability, and relatively low cost. However, solid-state batteries are the next generation of electric car batteries, as they offer higher energy density, faster charging times, and longer service life.

These batteries are still in the development stage, but once matured, they might revolutionize the electric vehicle industry. Ultimately, the type of electric car battery used will typically depend on a wide range of factors, including cost, performance requirements, and availability. Nevertheless, as the demand for electric vehicles continues to grow, research and development in electric car batteries will continue to advance, leading to more efficient and cost-effective options in the future.

How Electric Car Batteries Work

Electric car batteries are a crucial part of the electric car, as they store the energy needed to power the vehicle. The importance of these batteries cannot be overstated, as they determine how far an electric car can travel before needing a recharge. Generally, the battery’s capacity is measured in kilowatt-hours (kWh), with a higher number indicating greater capacity and therefore, longer driving distances.

However, the battery’s capacity is also affected by factors such as the weight of the car, the driving style, and the temperature. In fact, extreme temperatures can cause a battery’s capacity to diminish significantly, making it harder for a car to go long distances on a single charge. Despite these limitations, electric car batteries have come a long way in recent years, with advancements in technology continually being made to improve their capacity, durability, and charging speed.

As such, the future of electric cars looks promising, and with their continued growth in popularity, it is clear that electric car batteries will continue to play a critical role in the transition towards a more sustainable future.

Challenges in Electric Car Battery Manufacturing

Electric car batteries have become increasingly important in the automotive industry as more consumers turn to electric vehicles for their environmental benefits and cost savings. However, manufacturing these batteries poses several challenges. One of the biggest challenges is the sourcing of raw materials such as lithium and cobalt, which are used to make the batteries.

These materials are often found in unstable regions or countries with poor labor practices, making it difficult for manufacturers to ensure ethical sourcing. Another challenge is the complexity of the manufacturing process, which requires precise engineering and highly skilled labor. Additionally, the limited range of electric vehicles has led to the development of larger batteries, raising concerns about their safety and transportation.

Despite these challenges, manufacturers are continuously working to improve the manufacturing process to meet the growing demand for electric cars.

Innovations in Electric Car Battery Manufacturing

Electric car battery manufacturing has come a long way over the years, with new and improved innovations being introduced constantly. One such innovation is the use of solid-state batteries, which offer a range of benefits over traditional lithium-ion batteries, including faster charging times, longer life spans, and increased safety. Unlike their liquid-based counterparts, solid-state batteries use a solid electrolyte, making them less prone to leakage, explosion, and fire.

Another major innovation in electric car battery manufacturing is the use of recycled materials. In addition to being environmentally friendly, recycled materials can also reduce the cost of production, making electric cars more accessible and affordable for consumers. With these and other advancements in battery technology, the future of electric cars looks brighter than ever.

So, as demand for electric cars continues to rise, we can expect to see even more exciting innovations in battery manufacturing in the years to come.

New Materials and Techniques

Electric car batteries have come a long way in recent years, and manufacturers are constantly innovating to make them better and more efficient. One of the most exciting developments in this field is the use of new materials and techniques to produce batteries that are lighter, cheaper, and more environmentally friendly than their predecessors. For example, researchers are exploring the use of solid-state batteries, which use a solid electrolyte instead of a liquid one.

These batteries have the potential to hold more energy and charge faster than traditional lithium-ion batteries. Another area of focus is improving the manufacturing process itself. By using automated systems and machine learning algorithms, manufacturers can increase production efficiency and reduce waste, making electric cars more accessible to a wider range of consumers.

With these and other innovations on the horizon, the future of electric car batteries looks bright.

Advancements in Battery Recycling

Electric car battery production has advanced significantly in recent years. One significant development is in the innovation of the manufacturing process, which allows for easier recycling of batteries. Recyclable materials in the new batteries make them more eco-friendly and reduces waste.

The use of cobalt-free nickel batteries creates more sustainability in the manufacturing process while also ensuring longer-lasting battery life and better energy efficiency. Advances in battery recycling not only reduce waste and help the environment, but also increase the affordability and availability of electric cars and other electronic devices that rely on batteries. With these innovations, electric car batteries can now offer a more sustainable, cost-effective and eco-friendly solution for the future.

The Future of Electric Car Batteries

The electric car industry has grown exponentially over the past few years, and with that growth comes a sharp increase in demand for efficient and long-lasting batteries. As the focus shifts towards optimizing electric car batteries manufacturing, several exciting advancements are on the horizon. Scientists are working on developing solid-state batteries, which offer a higher energy density than conventional lithium-ion batteries.

This technology is still in the early stages, but it could revolutionize the industry by taking electric cars to the next level of efficiency and performance. Additionally, other researchers are exploring different materials for the anodes and cathodes of batteries, which could lead to improved energy storage and longer lifetimes. With innovations such as these being explored, it is an exciting time to be in the electric car industry.

As manufacturing techniques continue to improve, we can expect to see a steady increase in affordable and reliable electric cars on the market.

Conclusion

In conclusion, the world of electric car batteries manufacturing is charged with electric energy and innovative technology. From the production of lithium-ion batteries to the implementation of sustainable manufacturing processes, the industry is constantly evolving to meet the demands of a greener future. So, while we may still have a ways to go in terms of perfecting this technology, there’s no doubt that electric car batteries are currently powering us towards an exciting and eco-friendly future!”

FAQs

How do electric car batteries differ from traditional car batteries?

Electric car batteries use rechargeable lithium-ion cells, whereas traditional car batteries use lead-acid cells. Lithium-ion cells have a higher energy density and longer lifespan, making them ideal for electric vehicles.

What materials are commonly used in the manufacturing of electric car batteries?

Electric car batteries are primarily made of lithium, cobalt, nickel, and manganese. These materials are used to make the lithium-ion cells that power electric vehicles.

How long does it typically take to manufacture an electric car battery?

The manufacturing process for electric car batteries can vary depending on the size and complexity of the battery. However, it typically takes several hours to assemble and test a single battery.

How does the demand for electric car batteries affect the manufacturing process?

With the increasing demand for electric vehicles, the demand for electric car batteries has also risen. As a result, manufacturers have had to invest in new production facilities and technology to keep up with the demand. This has led to advancements in the manufacturing process and increased efficiency.