Powering Up the Future: The Role of Rare Earth Minerals in Electric Car Batteries

If you’re wondering how electric cars work, it’s worth knowing about their impressive battery technology. Unlike gas-powered cars, which rely on internal combustion engines, electric vehicles rely on batteries to store and release energy. But what’s fascinating about these batteries is that they are made up of rare earth minerals, which have significant environmental implications for their production and disposal.

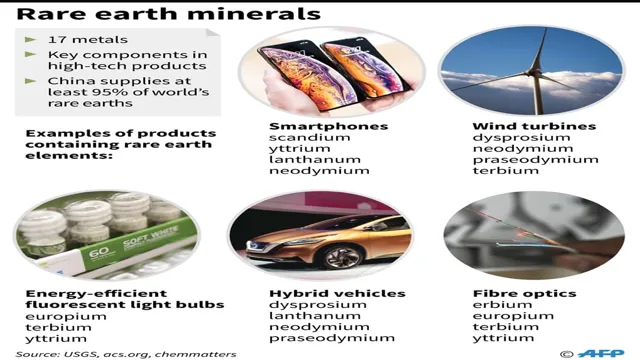

Rare earth minerals refer to a group of 17 elements that are crucial to the manufacturing of high-tech products, including electric cars. However, these elements are not actually rare in the earth’s crust. Rather, they are called “rare” because they are difficult and expensive to extract.

These minerals are found in various parts of the world, with China being the leading producer. While electric cars are certainly more environmentally friendly than their gas counterparts, their production can still have negative impacts on the environment. The mining, processing, and disposal of rare earth minerals can lead to pollution and other environmental harms.

As such, it’s important for electric car manufacturers to consider the environmental impact of battery production, as well as ways to improve battery recycling and disposal. Despite these challenges, electric cars are gaining popularity due to their numerous benefits for the environment and consumers. As more people switch to electric vehicles, the demand for rare earth minerals will continue to increase, making it crucial for manufacturers to prioritize sustainable and responsible practices in their production and disposal.

What Are Rare Earth Minerals?

Electric car batteries rely heavily on rare earth minerals, which are a group of 17 metallic elements with unique properties. These minerals are essential for the production of many automotive technologies, including electric and hybrid vehicle batteries. Rare earth minerals are highly sought after due to their various magnetic, conductive, and luminescent properties.

However, despite their immense importance, sourcing them can be challenging. The process for extracting rare earth minerals from the earth’s crust is complicated and expensive, which can create significant supply chain challenges for manufacturers and auto companies alike. Furthermore, rare earth minerals are not as readily available as other metals like copper and aluminum, making it even more challenging to meet the growing demand for electric cars.

This scarcity has driven up their prices, making it essential for companies to find alternative solutions to meet their needs without compromising their sustainability efforts.

Definition and Importance

Rare earth minerals are a group of 17 elements that are found in the earth’s crust. They are called “rare” because they are not found in large quantities in one location, although they are actually quite abundant in the earth’s crust. These minerals are used in many modern technologies, including electronics, wind turbines, and hybrid cars.

They are also used in defense technologies, such as missiles and jet engines. Due to their unique properties, rare earth minerals are difficult and expensive to extract from the ground. The importance of rare earth minerals lies in their critical role in modern technology and their scarcity, which makes them valuable resources.

Types of Rare Earth Minerals Used in Batteries

Rare earth minerals are a group of 17 elements that are crucial for the production of many modern technologies, including batteries. These minerals are called “rare earth” because they are not commonly found in large deposits and are difficult to extract. The most commonly used rare earth minerals in batteries are neodymium, praseodymium, and dysprosium.

These minerals are used to make powerful magnets that are essential components in the motors of electric vehicles (EVs) and wind turbines. Other rare earth minerals such as lanthanum and cerium are used in the production of the nickel-metal hydride batteries found in some hybrid vehicles. Although rare earths are critical to the manufacturing of many technologies, their supply is limited as they are primarily mined in China.

This has led to concerns about the availability of these minerals and the need for increased exploration and recycling of rare earths.

Electric Car Batteries & Rare Earth Minerals

Electric car batteries have become a modern marvel in terms of their environmental sustainability and efficiency compared to traditional gasoline-powered vehicles. However, there is a hidden component in the production of these batteries that many people are unaware of – rare earth minerals. These minerals are essential to the production of electric car batteries, specifically for the magnets and other components used in the battery’s construction.

The problem with rare earth minerals is that they are not readily available worldwide, and the production of these minerals can have negative environmental impacts if not managed properly. As the demand for electric cars grows, so will the demand for these minerals, thus highlighting the need for sustainable mining practices and research into alternative materials. While rare earth minerals may be essential to the production of electric car batteries, it is essential to take a holistic approach to their sourcing and consider the long-term environmental impact to promote a truly sustainable future.

Why Are Rare Earth Minerals Essential for Electric Car Batteries?

Rare earth minerals are essential for the production of electric car batteries due to their unique properties. These minerals are actually a group of 17 elements that are not found in concentrated forms, making them challenging to extract and refine. However, they have become increasingly important to the electric car industry as they provide high energy storage capabilities, durability, and efficiency.

Without rare earth minerals, electric car batteries would not be able to function effectively or efficiently, and the cars would not be able to travel the long distances that are necessary for their practical use. In fact, the demand for rare earth minerals is expected to continue to increase along with the demand for electric cars. While there are some concerns about the environmental impact of mining and processing these minerals, experts agree that the benefits of using them for electric car batteries make it essential to find sustainable solutions for their extraction and production.

How Do Car Manufacturers Obtain Rare Earth Minerals for Their Batteries?

When it comes to electric car batteries, rare earth minerals play a crucial role in their production. These minerals are mined from various locations around the world, including China, Australia, and the US. The most commonly used rare earth minerals for electric car batteries include neodymium, praseodymium, and dysprosium.

These minerals are highly sought after by car manufacturers due to their unique magnetic and conductive properties, which make them essential components in the production of electric car motors and batteries. However, acquiring these minerals can be challenging, as they are not always readily available. To obtain the necessary rare earth minerals, car manufacturers often partner with mining companies and other suppliers to ensure a steady and reliable supply.

Additionally, efforts are underway to develop alternative materials that can replace rare earth minerals in electric car batteries, but so far, these efforts have been hindered by the high cost and limited availability of these materials. Despite the challenges, the demand for electric cars continues to rise, and manufacturers must find ways to obtain the rare earth minerals needed for their batteries.

Impact of Rare Earth Mining on the Environment

Rare Earth Mining Rare earth minerals are essential components for the manufacturing of various technological devices, including electric car batteries. However, the impact of rare earth mining on the environment cannot be ignored. The mining process heavily relies on toxic and harmful chemicals that are detrimental to the health of the surrounding ecosystem and local communities.

These chemicals, including sulfuric acid and hydrochloric acid, are used to extract and refine the minerals, leading to air and water contamination, soil degradation, and the destruction of habitats. Moreover, the radioactive waste generated by the mining process poses great risks to human and animal health for years to come. Despite the efforts to minimize the environmental impact, the demand for rare earth minerals continues to increase rapidly, leading to more potential harm to the already struggling environment.

As consumers, it is our responsibility to support sustainable practices and minimize the use of rare earth minerals in our daily lives.

Future of Electric Car Batteries & Rare Earth Minerals

As the world moves towards a more sustainable future, the demand for electric vehicles continues to grow. Electric car batteries, which power these vehicles, need rare earth minerals to function efficiently. However, these minerals are scarce and difficult to mine, leading to concerns about the sustainability of electric vehicles in the long run.

Researchers and manufacturers are exploring alternative materials and methods to reduce the reliance on rare earth minerals. One method being explored is to use recycled materials and develop new technology to increase battery lifespan and efficiency. Additionally, alternative materials such as zinc and sodium-ion batteries are being researched as potential replacements for rare earth mineral-dependent batteries.

As the technology and research continues to progress, the future of electric car batteries appears promising as more sustainable and efficient methods are discovered, reducing our reliance on rare earth minerals.

Research and Development of Alternative Minerals

The future of electric car batteries is highly dependent on rare earth minerals. However, the research and development of alternative minerals is an ongoing process that may revolutionize the industry. Rare earth minerals such as neodymium, praseodymium, and dysprosium are vital components of batteries, yet they are finite resources with limited availability.

Exploration and development of new sources of these minerals are imperative to meet the increasing demand for electric car batteries. Fortunately, various alternatives are being studied, such as nano phosphates, lithium, and cobalt-free batteries. Although these alternatives are still in their early stages of development, they have shown significant potential in terms of durability, longevity, and cost-effectiveness.

Scientists and engineers are working tirelessly to make these alternative minerals a more sustainable option for the future of electric cars. The transition to alternative minerals may take some time, but it will undoubtedly benefit the planet by reducing the environmental impact of mining rare earth minerals.

Sustainability Initiatives in the Electric Car Industry

As the electric car industry continues to grow, sustainability initiatives have become a top priority. One aspect that is particularly important is the future of electric car batteries and rare earth minerals. Currently, most electric car batteries rely on lithium-ion technology, which requires rare earth minerals such as cobalt and nickel.

Unfortunately, the mining and extraction of these minerals can be environmentally damaging and can also have social and human rights implications. Fortunately, there are alternatives on the horizon, such as solid-state batteries, which use non-flammable and non-toxic materials that are easier to recycle. Additionally, some companies are exploring the use of other materials, such as sodium-ion or zinc-air batteries, which do not require rare earth minerals at all.

While there is still a long way to go before these technologies are widely adopted, there is hope that the future of electric car batteries will be more sustainable and ethical.

Conclusion

In conclusion, electric car batteries may require rare earth minerals, but don’t let that shock you. These minerals may be scarce, but their benefits are abundant, enabling cleaner and more efficient transportation. So, even though there may be a bit of a charge for these minerals, the switch to electric cars is electrifyingly worth it in the long run.

“

FAQs

Why are rare earth minerals important for electric car batteries?

Rare earth minerals are important for electric car batteries because they are used in the production of permanent magnets necessary for the car’s motor and in the creation of high-capacity rechargeable batteries.

Which rare earth minerals are commonly used in electric car batteries?

The most commonly used rare earth minerals in electric car batteries include neodymium, praseodymium, and dysprosium.

What are the environmental impacts of mining rare earth minerals for electric car batteries?

Mining rare earth minerals for electric car batteries can have significant environmental impacts, including habitat destruction, water pollution, and soil contamination.

Are there any alternatives to using rare earth minerals in electric car batteries?

While alternatives to rare earth minerals are being researched, they are not yet commercially viable. However, some manufacturers are working to reduce the reliance on these minerals by designing more efficient motors and using recycled materials.