Exploring the Future of Electric Cars: Unveiling the Raw Materials Behind Efficient Battery Performance

Electric cars are quickly becoming the norm on our roads, but have you ever wondered what goes into making their batteries? The answer lies in the raw materials used to create them, and the question of sustainability. Electric car batteries depend on a wide range of metals and minerals, including cobalt, lithium, nickel, and graphite. These materials may be found in abundance around the world, but mining them can be a costly and environmentally damaging process.

As more and more electric cars hit the market, the need for sustainable sourcing and recycling of raw materials in their production becomes increasingly important. Join us as we explore the ins and outs of electric car battery raw materials, and what the future might hold for this rapidly evolving industry.

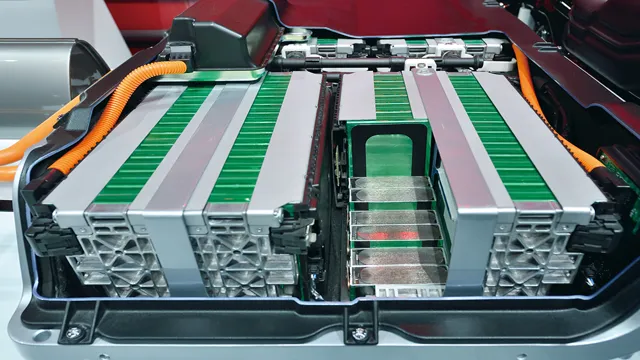

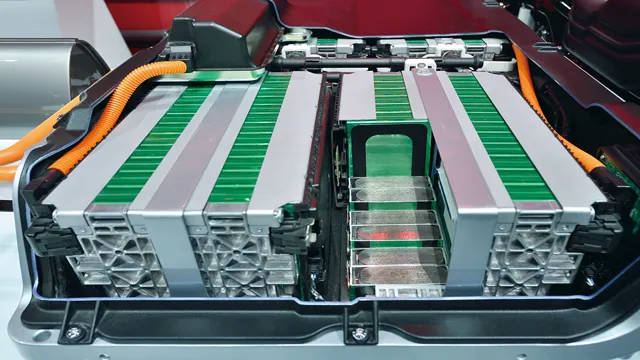

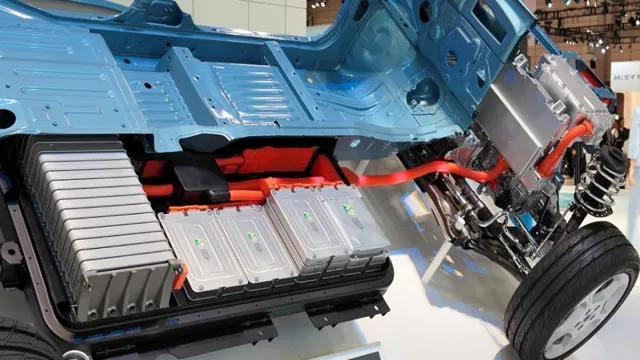

Lithium Ion Batteries

One of the key components of electric car batteries is the raw materials used in the manufacturing process. Lithium ion batteries are the most common type of battery used in electric cars, and they require a variety of raw materials to function properly. These include lithium, cobalt, nickel, and manganese.

Lithium is the most important of these materials, as it is the primary component of the battery’s electrolyte. Cobalt is also a critical component, as it helps to stabilize the battery’s performance and extend its lifespan. Nickel and manganese are used in smaller amounts, but they still play important roles in ensuring that the battery operates efficiently.

Overall, the raw materials used in electric car batteries are carefully chosen to ensure that the battery is both reliable and long-lasting, making them a critical factor in the growing popularity of electric vehicles.

Cobalt, Nickel, and Manganese

Lithium Ion batteries are an incredibly popular choice for powering portable electronic devices, from smartphones to laptops and beyond. These powerful batteries rely on a number of key components, including the metals cobalt, nickel, and manganese. These metals are essential for ensuring the efficient operation of lithium ion batteries, as they help to regulate the flow of electrons and promote optimal performance.

While there are concerns about the ethical sourcing of these metals, they remain critical for the development of ever-more advanced batteries that can power our devices for longer and more reliably than ever before. For those looking to make a positive impact on the environment while still enjoying the benefits of powerful lithium ion batteries, it’s important to choose products that promote sustainable and ethical sourcing practices. By doing so, you can rest assured that you’re supporting a brighter future for both the planet and your favorite devices.

Market Demand for Raw Materials

The market demand for raw materials has been seeing a significant increase in recent years, and a key player driving this growth is the lithium-ion battery market. As the world moves further into the age of electric vehicles, renewable energy, and portable electronics, the reliance on lithium-ion batteries is only going to continue to grow. This has led to a surge in demand for lithium, one of the primary materials used in creating these batteries.

However, this demand has also created concerns around the availability of this resource. Though lithium deposits exist all around the world, production can be limited due to the lengthy and costly extraction process, leading to discrepancies in supply and demand. Nonetheless, the industry is finding new ways to increase production to meet the market demand, and the future looks bright for the lithium-ion battery market.

Sourcing and Sustainable Practices

As demand for electric cars continues to rise, there is increased attention on the sourcing and sustainable practices of the raw materials used to make their batteries. Electric car batteries contain several materials, including lithium, cobalt, nickel, manganese, and graphite. These materials are finite and typically sourced from mines, some of which have been accused of poor working conditions and environmental degradation.

To address these concerns, there is a push towards responsible sourcing and recycling of materials. This includes initiatives such as guaranteeing fair wages and safe working conditions for miners, implementing traceability systems to ensure transparency in the supply chain, and developing new technologies to recycle and reuse materials. By promoting sustainable practices, the electric car industry can not only reduce its impact on the environment but also improve the livelihoods of those involved in the supply chain.

Mining and Extraction Challenges

When it comes to mining and extraction, one of the major challenges is sourcing and maintaining sustainable practices. The extraction of materials from the Earth can have a huge impact on the environment and surrounding communities. Therefore, it is essential for mining companies to use sustainable practices that minimize their impact on the environment and ensure the long-term availability of resources.

One way that this can be achieved is through responsible sourcing practices. This involves working with suppliers and partners to ensure that materials are ethically sourced, reducing the risk of environmental and social damage. Additionally, mining companies can implement sustainable practices such as reducing waste, minimizing water consumption, and exploring alternative energy sources.

By implementing these initiatives, mining companies can help reduce their environmental impact and ensure that the resources they rely on are available for future generations.

Recycling and Reuse Solutions

When it comes to recycling and reuse solutions, the key to sustainability is not only in the end product but also in the sourcing and manufacturing process. As consumers, we have the power to demand transparency in the supply chain and encourage companies to adopt sustainable practices. It is important to choose products made from recycled materials and to support brands that prioritize waste reduction and resource conservation.

However, simply relying on recycling as a solution is not enough. We need to shift towards a circular economy model that prioritizes reuse and designing products with recyclability in mind. It’s like building a puzzle where every piece is designed to fit together and form a complete picture.

By embracing sustainable practices and choosing products that support them, we can contribute towards a brighter and more sustainable future for our planet.

Supply Chain Transparency

When it comes to supply chain transparency, sourcing and sustainable practices play a crucial role. As consumers become increasingly aware of the environmental impact of their purchases, companies must ensure they ethically source their products and implement sustainable practices to reduce their carbon footprint. This not only benefits the environment but also enhances the brand’s reputation and customer loyalty.

For example, a fashion brand could source their cotton from a Fairtrade supplier and use eco-friendly dyes to reduce water usage and pollution. Overall, by prioritizing ethical and sustainable sourcing practices, companies can ensure supply chain transparency and build a more sustainable future for all.

Future Innovations and Alternatives

Electric car batteries are powered by various raw materials that include minerals such as lithium, cobalt, and nickel. Recently, there has been growing concern about the ethical sourcing of these materials, prompting many automakers to explore new alternatives. With the global demand for electric vehicles on the rise, battery manufacturers are investing in sustainable and affordable materials to keep up with production.

For example, some companies are exploring the use of recycled batteries to reduce the reliance on newly mined materials. Others are experimenting with using graphene, which is a form of carbon that is lightweight, durable, and abundant, making it an ideal material for use in battery technology. These innovations not only improve the environmental impact of electric vehicles by reducing waste and pollution but also offer a more cost-effective and long-lasting solution for consumers.

As electric cars become increasingly mainstream, we can expect to see continued advancements and innovative solutions in the production of electric car batteries.

Solid State Batteries

Solid State Batteries Solid state batteries are quickly becoming the preferred choice for many electronics and transportation industries. These batteries use solid electrolytes instead of the traditional liquid ones found in regular batteries. This makes them more efficient, safer, and longer-lasting.

Solid state batteries also have a higher energy density, which means they can hold more charge and last longer. Additionally, they are more environmentally friendly as they contain less toxic chemicals and can be recycled more easily. As technology continues to evolve, solid state batteries will become even more important in powering devices and vehicles in the future.

Their potential for being used in electric cars and other sustainable transportation options makes them a valuable innovation that could revolutionize the way we power our lives.

Hydrogen Fuel Cells

Hydrogen fuel cells are considered to be an alternative energy source with great potential for the future. With the need for cleaner energy sources increasing, hydrogen fuel cells provide a promising solution that produces only water vapor and electricity as byproducts. Unlike fossil fuels, hydrogen is infinitely abundant and can be produced from renewable resources such as solar or wind power.

Despite their advantages, hydrogen fuel cells face some challenges, including cost and infrastructure. However, researchers and innovators are constantly working to address these challenges and improve the technology. With the potential to power everything from cars to homes, hydrogen fuel cells are a promising and innovative solution for a cleaner and more sustainable future.

Conclusion

In conclusion, the raw materials that go into making electric car batteries are not only essential for powering our vehicles, but also hold the potential to revolutionize our entire transportation industry. From lithium and cobalt to nickel and manganese, these elements may seem unassuming, but their impact on our lives and the environment cannot be understated. So, let’s keep innovating, exploring new solutions, and pushing the limits, because who knows? Perhaps the future of transportation will be powered by cheese or kryptonite- anything is possible!”

FAQs

What are some common raw materials used in electric car batteries?

Some common raw materials used in electric car batteries include lithium, cobalt, nickel, and graphite.

Are electric car batteries environmentally friendly?

While electric car batteries do have some environmental impacts during production and disposal, they are generally considered to be more environmentally friendly than traditional gasoline-powered cars.

How long do electric car batteries typically last?

The lifespan of an electric car battery can vary depending on factors such as usage and charging habits, but most electric car batteries are expected to last between 8 to 10 years.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled. In fact, recycling these batteries is important for reducing environmental impacts and conserving raw materials.