Revving Up the Future: A Beginner’s Guide to Electric Car Battery Assembly

Electric car battery assembly is the backbone of electric vehicle technology. Without a reliable and efficient battery pack, electric cars would not be as popular and practical as they are today. Simply put, the battery is the heart of an electric vehicle, supplying power to the electric motor and all the onboard electronics.

But what goes into the production of an electric car battery pack? How are the batteries assembled, and what technologies are used to ensure their safety and performance? We will explore these questions and more in this blog post, delving into the intricacies of electric car battery assembly and its importance in the greater context of clean energy. Join us as we take a closer look at the technology behind electric car battery assembly and learn how this crucial component is helping to shape the future of transportation. Whether you’re an electric car owner, a technology enthusiast, or simply curious about the latest advances in green energy, this post is sure to provide you with valuable insights into the world of electric vehicle technology.

So buckle up and let’s dive in!

Why Use Electric Car Battery Assembly?

There are many compelling reasons to use electric car battery assembly when building electric vehicles. First and foremost, electric car battery assembly allows for increased efficiency and reliability in the performance of the vehicle. This is because electric car battery assembly uses specialized cells and materials that are specifically designed to work together in order to maximize energy output and storage.

Additionally, electric car battery assembly can also help to reduce emissions and lower carbon footprints, making it a more environmentally-friendly choice than traditional gasoline-powered vehicles. Furthermore, electric car battery assembly can also help to increase convenience and ease of use, as electric vehicles can be charged at home or at public charging stations, reducing the need for frequent trips to the gas station. Overall, electric car battery assembly is a game-changing technology that is revolutionizing the automotive industry and pushing us towards a more sustainable and eco-friendly future.

Efficient Electricity Usage

Electric car battery assembly is a smart technology that can revolutionize the way we use energy. It’s efficient, reliable, and eco-friendly, making it a great choice for modern consumers who want to make positive changes for the environment. By utilizing electric car battery assembly, we can save energy and reduce our carbon footprint.

This technology is particularly useful for those who travel frequently or live in urban areas where pollution is a major problem. Electric cars are equipped with batteries that can store energy and power the car’s electric motor. With proper maintenance and usage, these batteries can last for years, making them a cost-effective option.

Overall, electric car battery assembly is an innovative solution to improve efficiency and reduce energy usage, making it an excellent choice for environmentally-conscious individuals who want to make a positive impact on our planet.

Environmentally Friendly

Electric car battery assembly is a great choice for those who are environmentally conscious. Compared to traditional internal combustion engines, electric cars produce significantly fewer pollutants and greenhouse gases. In addition, the batteries used in these cars can often be recycled, reducing their impact on the environment even further.

Another advantage of electric car battery assembly is that it can significantly reduce the cost of fuel. While the initial cost of purchasing an electric vehicle may be higher than that of a traditional car, the long-term savings of not having to buy gasoline can more than make up for it. So, if you’re looking to reduce your carbon footprint and save money in the long run, considering an electric car with battery assembly is a wise choice.

Electric Car Battery Assembly Components

Electric car battery assembly components are the heart of an electric car’s power system. The electrical components of the battery assembly are responsible for converting the direct current (DC) stored in the battery into the alternating current (AC) that powers the car’s motor. The battery assembly includes several essential components that work together to deliver a smooth and efficient electric power system.

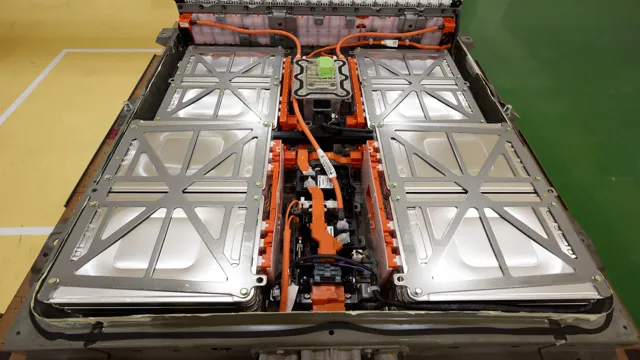

These components include the battery pack, the battery management system (BMS), the electrical connectors, the cooling system, and the charging system. Each of these components plays a critical role in the proper operation of the electric car battery assembly. The battery pack is the primary power source and is typically located beneath the car’s floor.

The BMS manages the battery’s functions, such as charging and discharging, while the electrical connectors connect the battery to the rest of the car’s electrical system. The cooling system helps to regulate the battery’s temperature, while the charging system allows the battery to recharge quickly and efficiently. With all these components working together, the electric car battery assembly can provide a reliable and efficient power source for the car’s motor, making electric cars a practical and sustainable transportation option for the future.

Battery Cells

Electric Car Battery Assembly Components When it comes to electric cars, the most important component is the battery cell. The battery assembly consists of many individual cells, each of which plays a crucial role in storing and supplying energy to the car’s motor. These cells are connected in series and parallel to create a large, powerful battery pack that can power the entire car.

The battery cells are typically made of lithium-ion, which has become the industry standard due to its high energy density and long life. However, there are several other types of batteries, such as nickel-metal hydride and solid-state, that are being developed for use in electric cars. In addition to the battery cells, the assembly includes other crucial components such as the Battery Management System (BMS), which monitors and controls the charging and discharging of the battery to ensure it remains safe and efficient.

Overall, the battery assembly represents a major technological advancement in the automotive industry, paving the way for a more sustainable and environmentally-friendly future.

Battery Management System

When it comes to the electric car battery, the battery management system (BMS) is a crucial component to consider. The BMS ensures that the battery operates safely, efficiently, and with a long lifespan. It monitors the temperature, state of charge, and voltage of each battery cell, preventing overcharging or discharging.

The BMS also communicates with the car’s main computer, which adjusts the car’s performance based on the battery’s condition. Furthermore, the BMS can detect and isolate any dead or malfunctioning cells, preventing them from damaging the whole battery or causing a fire hazard. So, the BMS is like the conductor of an orchestra, making sure every instrument is in tune and playing its best to create a beautiful symphony.

Without the BMS, an electric car would not function safely or effectively.

Thermal Management System

A crucial component of the electric car battery assembly is the thermal management system, which is responsible for regulating the temperature of the battery pack. The thermal management system ensures that the battery cells operate within their optimal temperature range, which prolongs the battery’s lifespan, ensures optimal performance, and reduces the risk of thermal runaway. The thermal management system consists of several components, such as the coolant, radiator, pump, and temperature sensors.

Think of the thermal management system as the air conditioning unit of your home. It keeps the battery pack cool during hot summer days and warm during cold winter nights. Without this system, the battery cells would overheat, causing damage to the cells and reducing their performance.

Over time, this could lead to a shorter lifespan and potentially dangerous situations. The coolant circulates through the battery pack, carrying away heat generated during charging and discharging, and dissipating it through the radiator. The pump regulates the flow of the coolant, ensuring that it reaches all parts of the battery pack.

Temperature sensors measure the temperature of the battery cells and send signals to the battery management system, which adjusts the cooling or heating accordingly. In summary, the thermal management system is a vital component of the electric car battery assembly. It ensures that the battery pack operates within its optimal temperature range, maximizing performance, and lifespan.

Types of Electric Car Battery Assembly

Electric car battery assembly has evolved significantly with advancements in technology and innovation. There are three different types of electric car battery assemblies: cylindrical, pouch, and prismatic. Cylindrical batteries are the most widely used and are typically manufactured by Tesla, but they are also used by other manufacturers.

Pouch batteries have a lower profile and are better-suited for compact car designs. Prismatic batteries are similar to pouch batteries but are made up of square cells rather than rectangular cells. The most important factor when choosing a battery assembly type is determining the most effective balance between size, weight, power output, and energy density that best suits the vehicle’s needs.

Ultimately, the battery assembly type that will work best is dependent on the specific design and performance requirements of the electric vehicle in question.

Lithium-Ion Battery

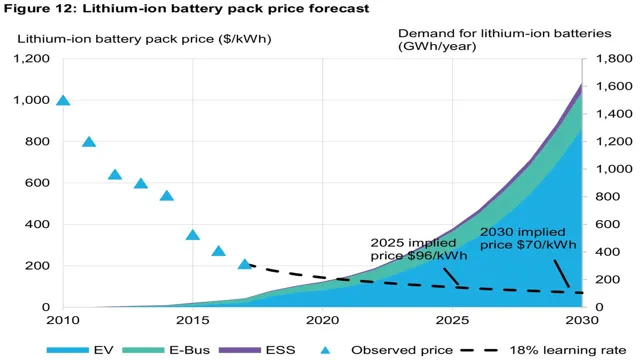

Lithium-Ion Battery When it comes to electric car batteries, there are several types of configurations that are used. Lithium-ion batteries are the most popular and commonly used type of battery in electric cars. These batteries are made up of individual cells that are chained together in series to create a higher voltage.

The number of cells used in the battery pack will determine the range of the electric car. Lithium-ion batteries are lightweight, efficient, and hold a high charge capacity. They can be rapidly charged and have a long cycle life, making them ideal for electric vehicles.

Many high-end electric car manufacturers use lithium-ion batteries in their vehicles, including Tesla, Nissan, and Chevrolet. These batteries offer a high level of performance and reliability, making them a popular choice for electric car owners.

Lead-Acid Battery

When it comes to electric car batteries, there are a few different types of assemblies to consider. One of the most common types is a lead-acid battery, which has been around for over 150 years and is used in many conventional cars as well. These batteries use lead plates and an electrolyte solution to store and release energy, and while they may not be as efficient or long-lasting as some of the newer battery technologies, they are still a relatively affordable and reliable option.

However, lead-acid batteries can be quite heavy and may not provide as much power as other types of batteries. Additionally, they require regular maintenance and can be hazardous if not handled properly. Overall, lead-acid batteries are a viable option for some electric car owners, but there are certainly other options available that may be better suited to certain use cases or preferences.

Nickel-Cadmium Battery

One of the main types of electric car battery assembly is the nickel-cadmium battery. This battery has been around for quite some time and is still commonly used in hybrid vehicles. One of the advantages of nickel-cadmium batteries is their ability to handle high currents, which makes them excellent for use in electric vehicles.

They are also known for their durability and long lifespan, making them an excellent choice for those who want a reliable and long-lasting battery option. However, nickel-cadmium batteries do have their disadvantages as well. They tend to be heavier and less energy-dense than some of the other battery options out there, which can make them less efficient in certain applications.

Additionally, they also have environmental concerns associated with their use since cadmium is a toxic heavy metal that can be harmful to ecosystems. Despite these drawbacks, nickel-cadmium batteries remain a popular option for some electric car manufacturers.

Electric Car Battery Assembly Maintenance

Maintaining the battery assembly in your electric car is crucial to ensure it performs at its best. Regularly checking and maintaining the battery assembly can help extend its lifespan and avoid expensive repairs down the line. It’s recommended to inspect the battery assembly every six months and to clean it as needed by removing any dirt or debris that could potentially harm the battery.

It’s also essential to keep the battery properly charged and avoid letting it completely drain, as this can cause irreversible damage. By taking care of your electric car battery assembly, you can ensure a safe and reliable driving experience while also reducing your carbon footprint.

Check Battery Health

Have you checked your electric car’s battery health lately? Battery assembly maintenance is crucial in keeping your electric vehicle running smoothly. A healthy battery can maximize your car’s range and efficiency, but a poorly maintained one can lead to reduced performance and even failure. Regularly checking the battery’s state of charge and monitoring its temperature can give you an idea of its overall health.

A good rule of thumb is to aim for a charge level of around 80% to 90% and avoid letting it dip below 20% whenever possible. Think of it like checking your own health vitals regularly. By keeping an eye on your battery health, you can catch any issues early and prevent costly repairs down the road.

Keep It Clean

Electric car batteries require regular maintenance to keep them in tip-top shape. One of the most important aspects of maintaining an electric car battery assembly is to keep it clean. This means regularly checking for any signs of dirt, grime, or debris on the battery terminals and ensuring that the connections are tight.

Any buildup of dirt or debris can cause a decrease in the battery’s performance, and can even cause permanent damage in some cases. To keep the battery clean, simply wipe the terminals with a clean cloth and use a wire brush to remove any stubborn buildup. It’s also important to keep the battery dry, as moisture can cause corrosion and reduce performance.

By keeping your electric car battery assembly clean and dry, you can ensure that it performs at its best for years to come.

Conclusion

In conclusion, assembling electric car batteries may seem like a daunting task, but it’s a spark of genius that’s changing the game in the automotive industry. It’s electrifying to see the advancements in battery technology that are revolutionizing the way we drive and reducing carbon emissions. So, let’s recharge our excitement for the future of transportation and get charged up for a cleaner, greener world.

“

FAQs

What is electric car battery assembly?

Electric car battery assembly is the process of putting together multiple individual battery cells to create a battery pack that can power an electric car.

Can an electric car battery assembly be repaired or replaced?

Yes, electric car battery assembly can be repaired or replaced, but it depends on the extent of damage, age of battery, and manufacturer’s warranty.

What is the typical lifespan of an electric car battery assembly?

The lifespan of an electric car battery assembly varies depending on how often it is charged, type of driving, and maintenance practices. Generally, it lasts for 8 to 10 years or around 100,000 miles.

How can the efficiency of electric car battery assembly be improved?

The efficiency of electric car battery assembly can be improved by developing more advanced battery chemistries, reducing the weight of battery components, and improving heat management. Research is ongoing in this field.